Cable recovery integrated treatment device

A comprehensive processing and cable technology, which is applied in the field of cable recycling comprehensive processing devices, can solve the problems of waste of leather materials and waste of core materials, and achieve the effects of avoiding secondary pollution, reducing social costs, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

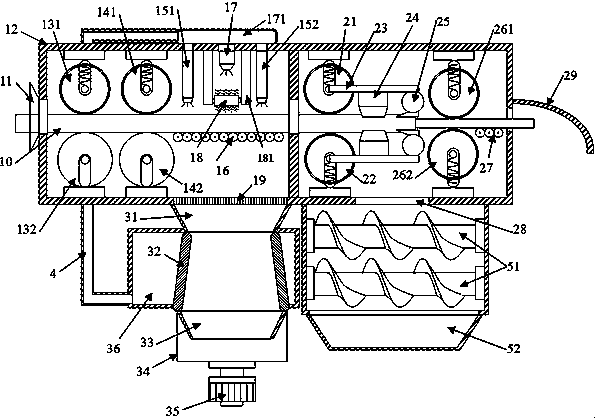

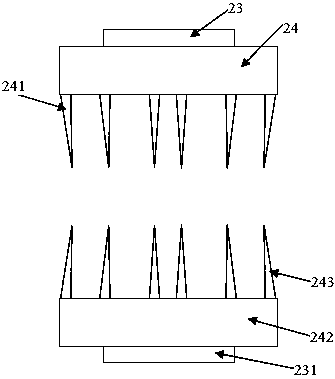

[0031] Further explanation in conjunction with accompanying drawings: as figure 1 with figure 2 The shown cable recycling comprehensive processing device includes a cleaning device, a peeling device, a water treatment device, a return pipe and a crushing and recycling device.

[0032] Such as figure 1 The cleaning device shown in the upper left part includes a cleaning device shell, a general cable inlet, a first pinch roller part, a first backup roller part, a second pinch roller part, a second backup roller part, a first high-pressure nozzle, The second high-pressure spray pipe, the first conveying roller part, the water spray pipe, the water spray box, the rotating cleaning brush part, the cable outlet of the cleaning device and the water filter net; the total cable entrance is arranged on the side wall of the cleaning device shell, The first pinch roller part and the first backup roller part are arranged up and down opposite to each other inside the shell of the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com