Arsenic-iron slag cement solidifying method with humic acid serving as additive

A technology of cement solidification and additives, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., to achieve the effect of cost saving, low price and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

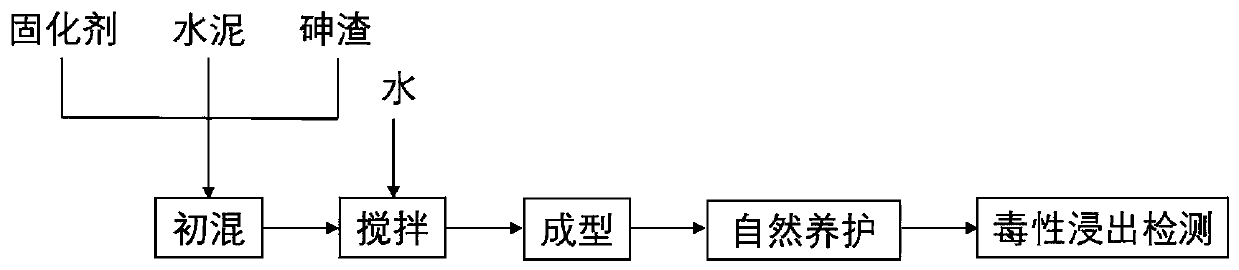

Method used

Image

Examples

Embodiment 1

[0022] Example 1. The arsenic slag in this example is specifically the iron salt arsenic slag of the acidic leaching solution of copper smelting dust. The main components of the arsenic slag are: Cu 0.57%, As 31.36%, Fe 23.49%, Zn 0.45%, Cd 0.31%, proceed as follows:

[0023] (1) According to the weight percentage of arsenic slag: Portland cement: humic acid = 100:15:1, take cement, arsenic slag and humic acid, grind them, pass through a 100-mesh sieve, and mix them evenly. After fully mixing the mixture with water, pour it into the mold and shake it fully. Natural curing at room temperature for 24 hours, demoulding;

[0024] (2) Curing the cured body after demolding at room temperature for 15 days;

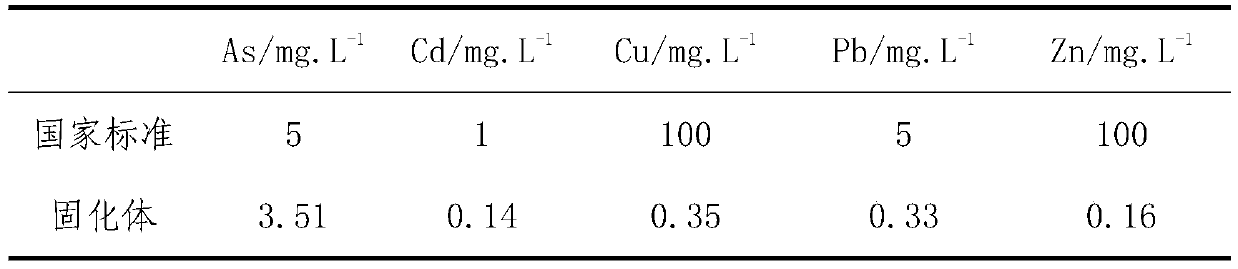

[0025] (3) Carry out toxicity leaching test on the solidified body of the obtained arsenic slag, detect the leaching concentration of As plasma, and analyze the leaching concentration of relevant toxic substances according to the GB5085.3-2007 hazardous waste identification sta...

Embodiment 2

[0028] Embodiment 2, the arsenic slag in the present embodiment is the arsenic slag in embodiment 1, and the method is carried out according to the following steps:

[0029] (1) According to the weight percentage of arsenic slag: Portland cement: humic acid = 100:25:2, take cement, arsenic slag and humic acid, grind them, pass through a 100-mesh sieve, and mix them evenly. After fully mixing the mixture with water, pour it into the mold and shake it fully. Natural curing at room temperature for 24 hours, demoulding.

[0030] (2) Curing the cured body after demolding at room temperature for 20 days;

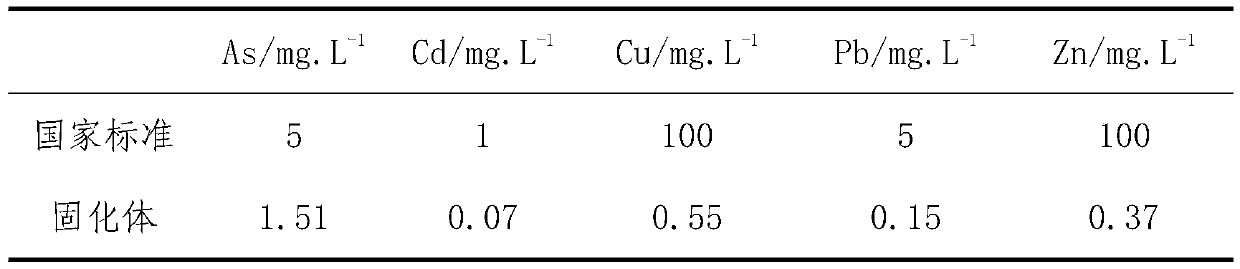

[0031] (3) Toxic leaching test was carried out on the solidified body of the obtained arsenic slag, and the leaching concentration of As plasma was detected, and the leaching concentration of relevant toxic substances was analyzed according to the GB5085.3-2007 hazardous waste identification standard, and the results are shown in Table 2.

[0032] Table 2 Concentration of each i...

Embodiment 3

[0034] Example 3, the arsenic slag in this embodiment is specifically the iron salt arsenic precipitation slag of the acidic leaching solution of copper smelting dust, and the main components of the arsenic precipitation slag are: Cu 0.03%, As 16.48%, Fe 16.3%, Zn 1.01%, Cd 0.45%. The method proceeds as follows:

[0035] (1) According to the weight percentage of arsenic slag: Portland cement: humic acid = 100:20:3, take cement, arsenic slag and humic acid, grind them, pass through a 100-mesh sieve, and mix them evenly. After fully mixing the mixture with water, pour it into the mold and shake it fully. Natural curing at room temperature for 24 hours, demoulding.

[0036] (2) The cured body after demoulding is naturally cured for 25 days at room temperature;

[0037] (3) Carry out toxicity leaching test on the solidified body of the obtained arsenic slag, detect the leaching concentration of As plasma, and analyze the leaching concentration of relevant toxic substances accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com