A multi-segment carbonization column with external natural circulation cooling

A natural circulation, carbonization tower technology, used in carbonate preparations, reagents, educts, etc., can solve the problems of low conversion rate, many equipment and complex process of external cooling carbonization tower, and achieve high carbonization conversion rate and extended operation. The effect of high cycle and absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

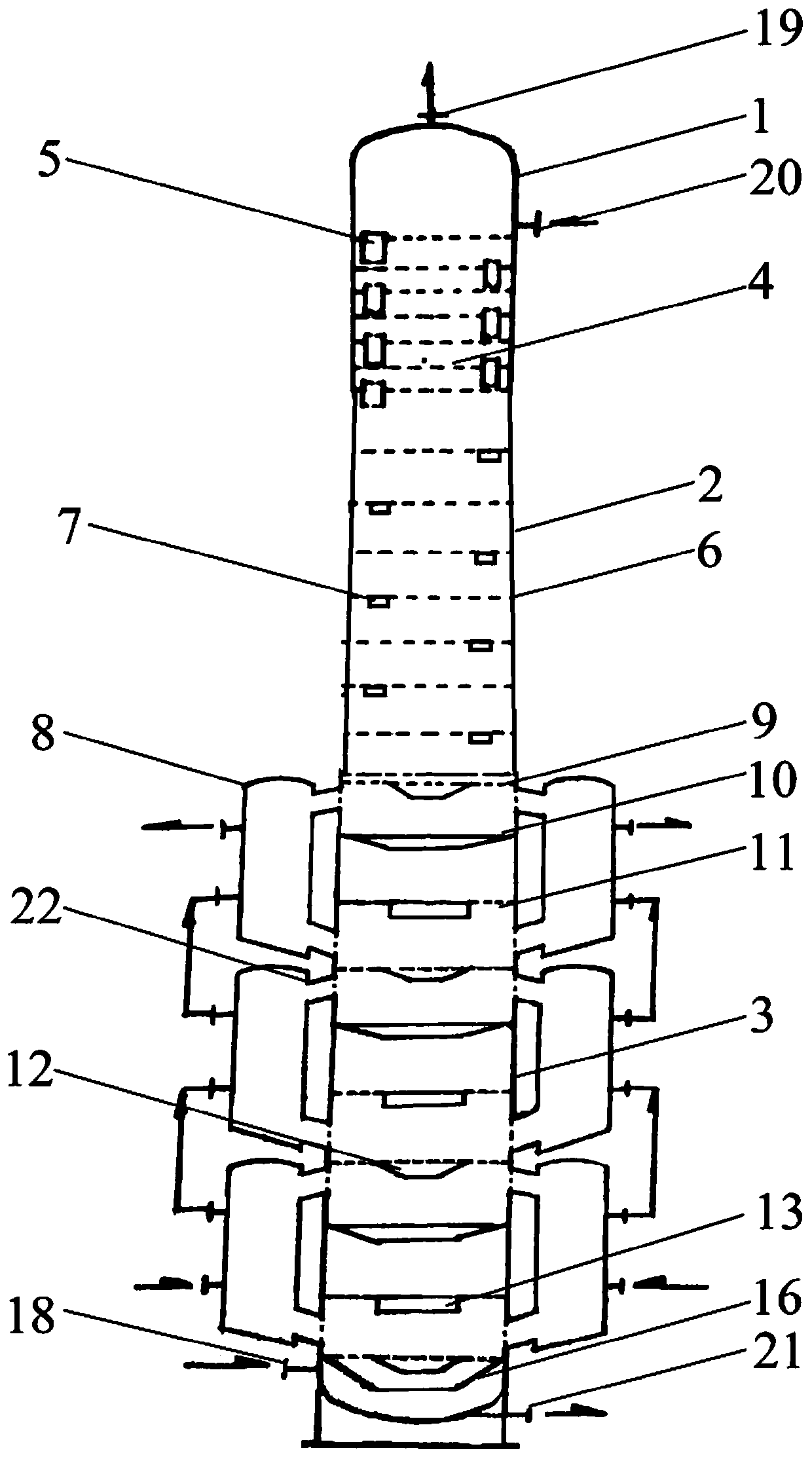

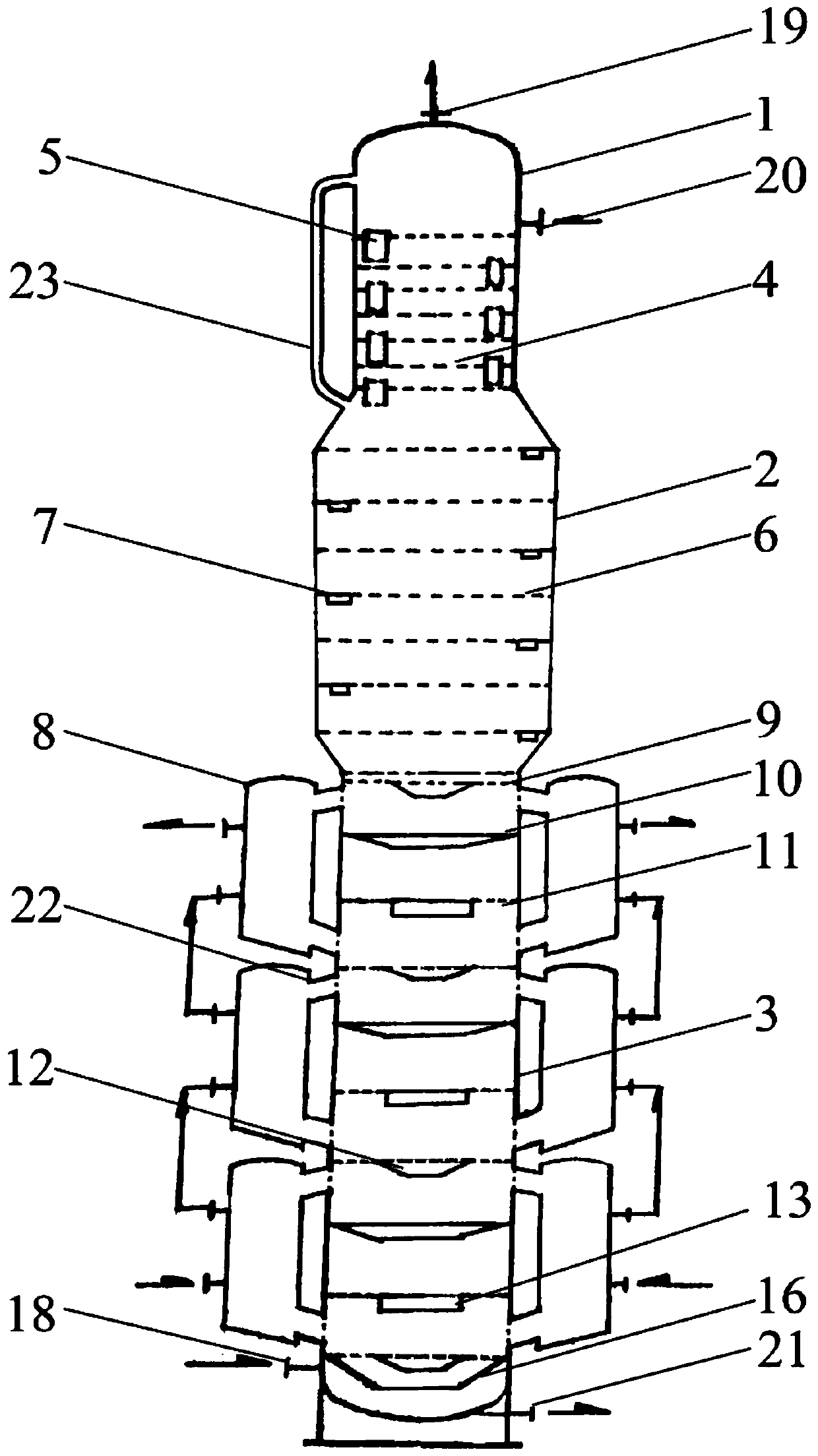

[0081] The large-scale carbonization tower that present embodiment is used for combined alkali method is as figure 2 As shown, its daily output of soda ash is 330-360 tons, and it is a three-stage external natural circulation cooling carbonization tower. The large-scale carbonization tower is composed of an upper tower body 1, a middle tower body 2 and a lower tower body 3, which are sequentially connected from top to bottom. The diameter of the upper tower body is 2.8m, the diameter of the middle tower body is 4.5m, and the lower tower body The diameter of the body is 3.5m, and the total height of the tower is 32m. The outer peripheral side wall of the lower tower body is provided with an air inlet 18 for passing gas into the tower, and the top of the upper tower body is provided with a tail gas outlet 19 for tail gas discharge; There is a liquid inlet 20 for liquid in the tower, and a liquid outlet 21 for liquid discharge is opened at the bottom of the lower tower body.

...

specific Embodiment 2

[0092] The large-scale carbonization tower that present embodiment is used for combined alkali method is as figure 2 As shown, its daily output of soda ash is 450-500 tons, and it is a three-stage external natural circulation cooling carbonization tower. The large-scale carbonization tower is composed of an upper tower body 1, a middle tower body 2 and a lower tower body 3, which are arranged sequentially from top to bottom. The diameter of the upper tower body is 3.0m, the diameter of the middle tower body is 5.0m, and the lower tower body The diameter of the body is 4.0m, and the total height of the tower is 32.7m. The air inlet 18, the tail gas outlet 19, the liquid inlet 20 and the liquid outlet 21 of the tower body are set the same as those in the specific embodiment 1. The setting of each section tray in the tower is the same as setting in the specific embodiment 1.

[0093] In the three-stage cooling zone of the lower tower body, four external coolers 8 with a diamet...

specific Embodiment 3

[0102] The large-scale carbonization tower that present embodiment is used for ammonia-soda method is as figure 1 As shown, it produces 500 tons of soda ash per day, and it is a three-stage external natural circulation cooling carbonization tower. The large-scale carbonization tower is composed of an upper tower body 1, a middle tower body 2 and a lower tower body 3, which are arranged sequentially from top to bottom. The diameter of the upper tower body is 4.5m, the diameter of the middle tower body is 4.5m, and the lower tower body The diameter of the body is 3.6m, and the total height of the tower is 33.2m. The air inlet 18, the tail gas outlet 19, the liquid inlet 20 and the liquid outlet 21 of the tower body are set the same as those in the specific embodiment 1.

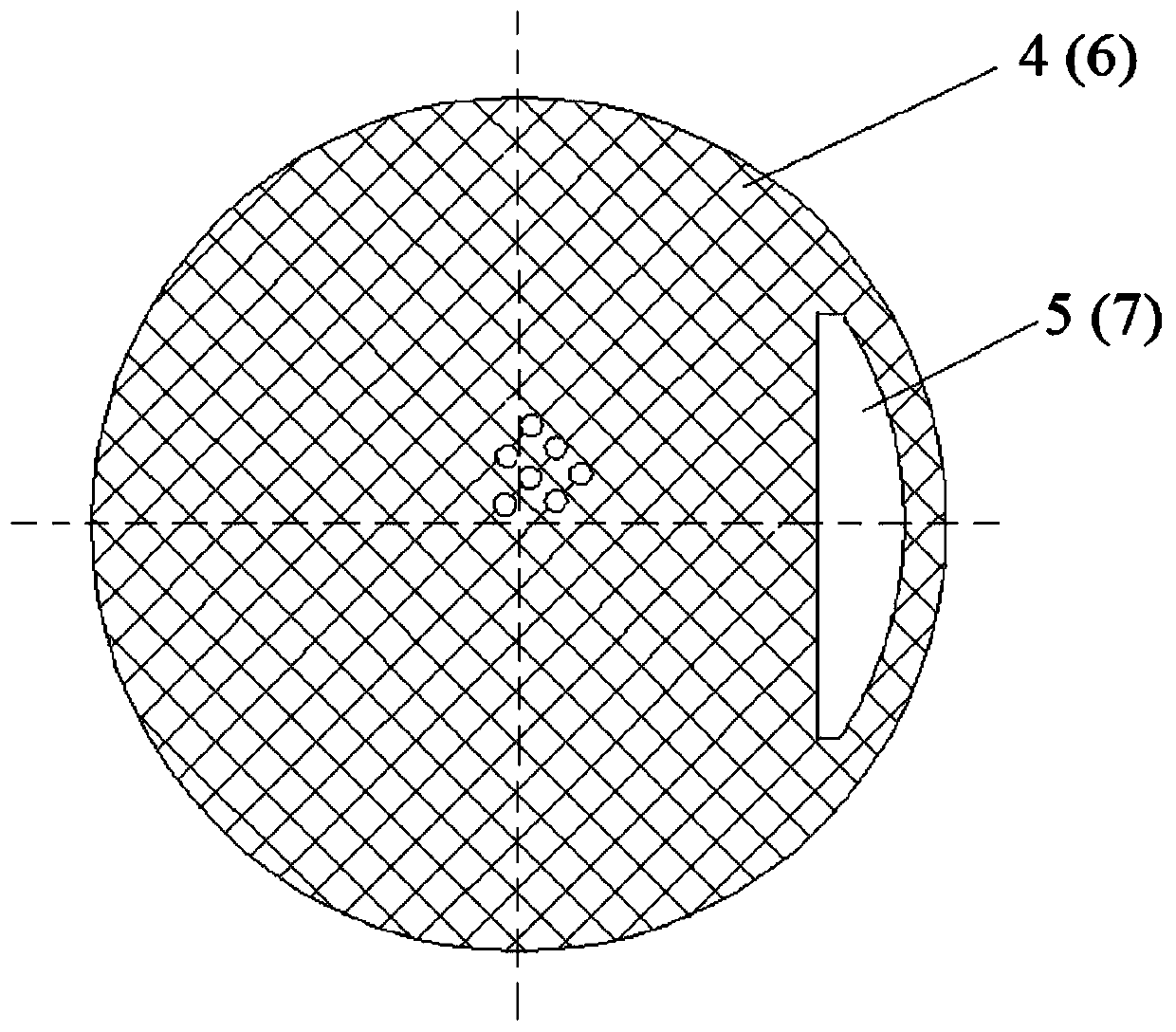

[0103] The tower is equipped with a number of sieve trays with a low opening ratio and a downcomer with the liquid phase as the continuous phase. In this specific embodiment, eight upper trays 4 are arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com