Online estimation system and method for basic heat value received by low-heat-value coal power generation as-fired fuel

A technology with low calorific value and fuel into the furnace, applied in information technology support systems, computing, relational databases, etc., can solve problems such as troublesome research and reference data, difficult problems, etc., and achieve the effect of eliminating unstable influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

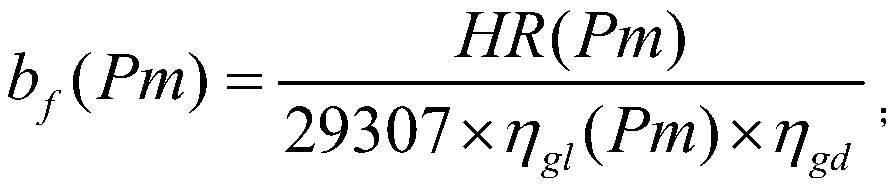

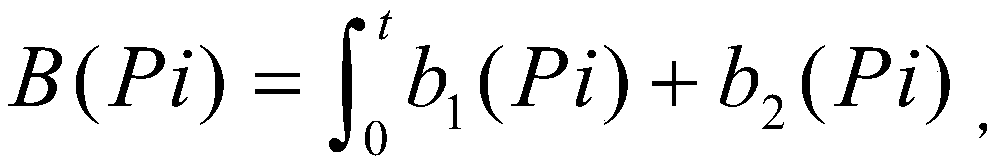

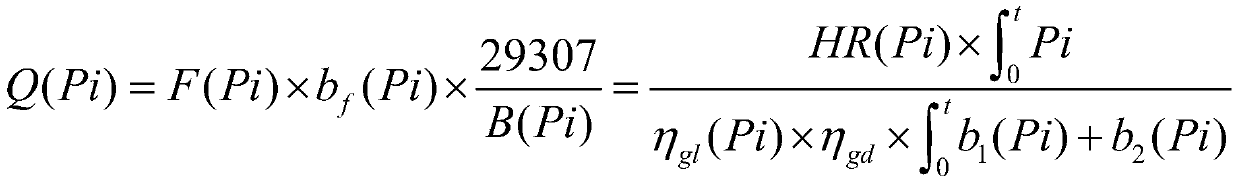

Method used

Image

Examples

Embodiment

[0085] Approval test of a unit in a power plant using low calorific value coal to generate electricity.

[0086] 1. Overview of main equipment:

[0087] The 2×330MW CFB unit of the power plant is equipped with DG1100 / 17.4-Ⅱ2 circulating fluidized bed boiler produced by Dongfang Boiler (Group) Co., Ltd., and the steam turbine is N330-16.7 / 538 / 538 steam turbine of Dongfang Steam Turbine Factory.

[0088] The boiler is subcritical, single drum, natural circulation, and circulating fluidized bed combustion. It is mainly composed of membrane water-cooled hearth, three air-cooled cyclone separators and a rear shaft flue (HRA) covered by an air-cooled wall. There are twelve panel-type superheater tube panels (six panels for the middle and high panels) and six panel-type reheater tube panels arranged on the front wall of the furnace, and two water-cooled evaporation panels are arranged on the rear wall. There are eight coal inlets arranged in front of the boiler furnace, which are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com