Preparation method of strongly fragrant beef tallow

A thick-flavored, butter technology, applied in the direction of oil/fat refining, edible oil/fat, and fat production, can solve the problems of high moisture and various hydrophilic impurities, heavy odor, and easy to generate a lot of foam, etc. Achieve the effect of low cost, stable storage and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

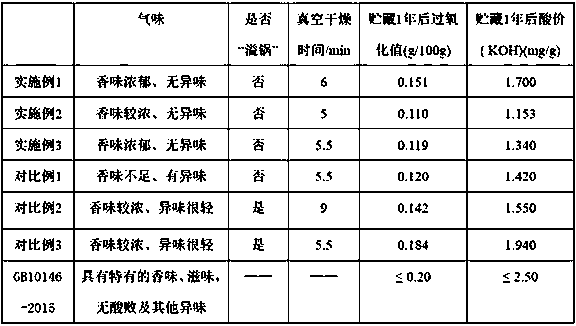

Examples

Embodiment 1

[0026] A production process of strong-flavored butter includes the following steps:

[0027] (1) Raw material crushing: crush the frozen raw fat into blocks of 7-10 cm;

[0028] (2) Fat lifting: The raw materials in step (1) are warmed and preheated to 85 ℃; 0.01% glucose and 0.1% ethanol are added for fat lifting, the temperature is controlled at 160±5 ℃, and the cooking time is 5.0 h;

[0029] (3) Coarse filtration: After placing the sedimentation to remove slag, use 60 mesh, 120 mesh, and 200 mesh stainless steel vibrating screens to filter in sequence;

[0030] (4) Fine filtration: separate first; add 0.1% perlite and filter;

[0031] (5) Vacuum drying: the refined filtered oil is vacuum dried to moisture content ≤0.5%;

[0032] (6) Homogenization: add 0.01% glycerol, at a temperature of 110 ℃, the first stage pressure is 15 MPa, and the second stage pressure is 3 MPa for homogenization; reduce the oil temperature to 60-80 ℃;

[0033] (7) Filling and cooling: After filling, cool to be...

Embodiment 2

[0035] A production process of strong-flavored butter includes the following steps:

[0036] (1) Raw material crushing: crush the frozen raw fat into blocks of 7-10 cm;

[0037] (2) Fat-lifting: the raw materials of step (1) are heated and preheated to 80 ℃; 0.2% maltose and 1.0% ethanol are added for fat-lifting, the temperature is controlled at 160±5 ℃, and the cooking time is 1.0 h;

[0038] (3) Coarse filtration: After placing the sedimentation to remove the slag, use 60 mesh, 80 mesh, 120 mesh, 180 mesh, 240 mesh, 300 mesh stainless steel vibrating screen in order to filter;

[0039] (4) Fine filtration: separate first; add 0.15% perlite and filter;

[0040] (5) Vacuum drying: the refined filtered oil is vacuum dried to moisture content ≤0.5%;

[0041] (6) Homogenization: add 0.5% glycerol, at a temperature of 80 ℃, the first stage pressure is 25 MPa, and the second stage pressure is 5 MPa for homogenization; reduce the oil temperature to 60-80 ℃;

[0042] (7) Filling and cooling: Af...

Embodiment 3

[0044] A production process of strong-flavored butter includes the following steps:

[0045] (1) Raw material crushing: crush the frozen raw fat into blocks of 7-10 cm;

[0046] (2) Fat lifting: The raw materials of step (1) are heated and preheated to 80 ℃; fructose 0.1% and ethanol 0.05% are added for fat lifting, the temperature is controlled at 160±5 ℃, and the cooking time is 2.5 h;

[0047] (3) Coarse filtration: After placing the sedimentation to remove the slag, use 60 mesh, 120 mesh, 180 mesh, 240 mesh, 300 mesh stainless steel vibrating screen in order to filter;

[0048] (4) Fine filtration: separate first; add 0.12% perlite and filter;

[0049] (5) Vacuum drying: the refined filtered oil is vacuum dried to moisture content ≤0.5%;

[0050] (6) Homogenization: add 0.2% glycerin, at a temperature of 100 ℃, the first stage pressure is 20 MPa, and the second stage pressure is 4 MPa for homogenization; reduce the oil temperature to 60-80 ℃;

[0051] (7) Filling and cooling: After fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com