Upright wood dust granulation machine facilitating feeding

A pellet machine, vertical technology, applied in the field of wood processing, can solve the problems affecting the quality and efficiency of pellet forming, affecting the compactness of pellets, and unstable material entry, to avoid blockage, improve quality, and improve the effect of compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

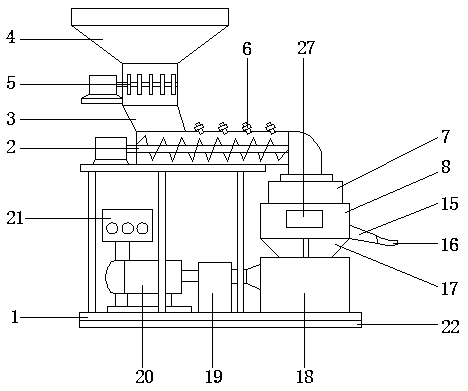

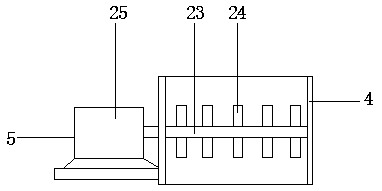

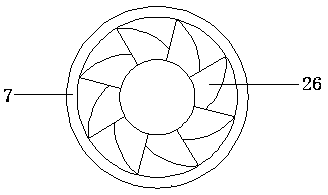

[0024] see Figure 1-Figure 5 As shown, the present invention provides a technical solution: a vertical wood pellet machine that is convenient for feeding, including a base 1, and the left side of the top of the base 1 is connected with a horizontally placed screw conveyor 2 through a support frame, which can stabilize and quickly The material is transported into the granulator, which improves the efficiency of feeding. The feeding port of the screw conveyor 2 is obliquely connected with a feeding pipe 3, and the top of the feeding pipe 3 is connected with a feeding hopper 4, and the feeding A feeder 5 is installed at the bottom of the inner cavity of the bucket 4 to avoid material blockage. The top of the spiral tube of the screw conveyor 2 is evenly connected with a spray nozzle 6, which can atomize the material and increase the humidity of the material. The discharge port of the conveyor 2 is connected with a material gathering box 7, and the bottom of the material gatherin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com