A kind of aluminum base mofs/chitosan composite microsphere and its preparation method and application

A technology of composite microspheres and chitosan, which is applied in the field of environmental science and engineering, can solve the problems of decreased adsorption performance of MOFs, low adsorption efficiency, difficult separation and recovery, etc., and achieves low requirements for equipment conditions, low cost and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of aluminum-based MOFs / chitosan composite microspheres

[0043] Disperse 5.00 g of monomeric aluminum-based MOFs in 95.00 g of deionized water, stir evenly and then heat. During the heating process, slowly add 0.8 g of cross-linking agent sodium alginate, and cool to room temperature after complete dissolution to obtain a mixed solution. Then 1.0g chitosan and 2.0g anhydrous CaCl 2 Dissolve in 1wt% acetic acid aqueous solution to obtain a mixed solution of chitosan-calcium chloride, and finally add the mixed aqueous solution of aluminum-based MOFs-sodium alginate to the chitosan-calcium chloride solution dropwise at a flow rate of 10mL / min. React in the mixed solution to form balls, filter after standing for 12 hours, wash with deionized water, and freeze-dry to prepare the aluminum-based MOFs / chitosan composite microspheres.

Embodiment 2

[0045] Preparation of aluminum-based MOFs / chitosan composite microspheres

[0046]Disperse 5.00 g of monomeric aluminum-based MOFs in 95.00 g of deionized water, stir evenly and then heat. During the heating process, slowly add 0.8 g of cross-linking agent sodium alginate, and cool to room temperature after complete dissolution to obtain a mixed solution. Then 1.5g chitosan and 2.0g anhydrous CaCl 2 Dissolve in 1wt% acetic acid aqueous solution to obtain a mixed solution of chitosan-calcium chloride, and finally add the mixed aqueous solution of aluminum-based MOFs-sodium alginate to the chitosan-calcium chloride solution dropwise at a flow rate of 10mL / min. React in the mixed solution to form balls, filter after standing for 12 hours, wash with deionized water, and freeze-dry to prepare the aluminum-based MOFs / chitosan composite microspheres.

Embodiment 3

[0048] Preparation of aluminum-based MOFs / chitosan composite microspheres

[0049] Disperse 5.00 g of monomeric aluminum-based MOFs in 95.00 g of deionized water, stir evenly and then heat. During the heating process, slowly add 0.8 g of cross-linking agent sodium alginate, and cool to room temperature after complete dissolution to obtain a mixed solution. Then 2.0g chitosan and 2.0g anhydrous CaCl 2 Dissolve in 1wt% acetic acid aqueous solution to obtain a mixed solution of chitosan-calcium chloride, and finally add the mixed aqueous solution of aluminum-based MOFs-sodium alginate to the chitosan-calcium chloride solution dropwise at a flow rate of 10mL / min. React in the mixed solution to form balls, filter after standing for 12 hours, wash with deionized water, and freeze-dry to prepare the aluminum-based MOFs / chitosan composite microspheres.

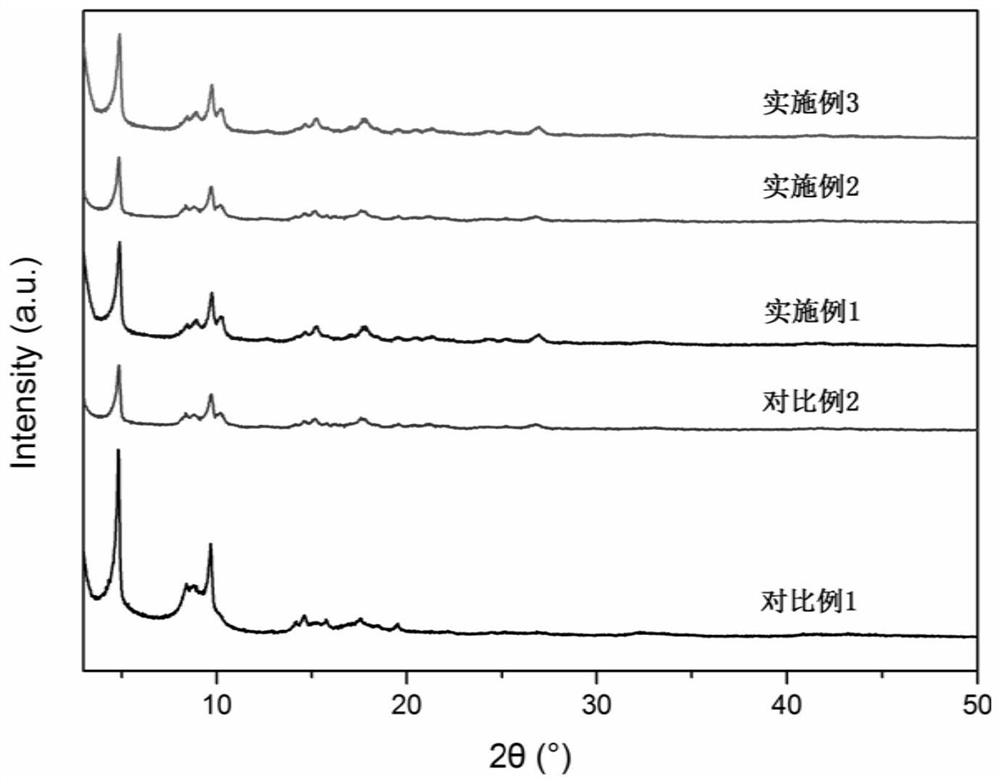

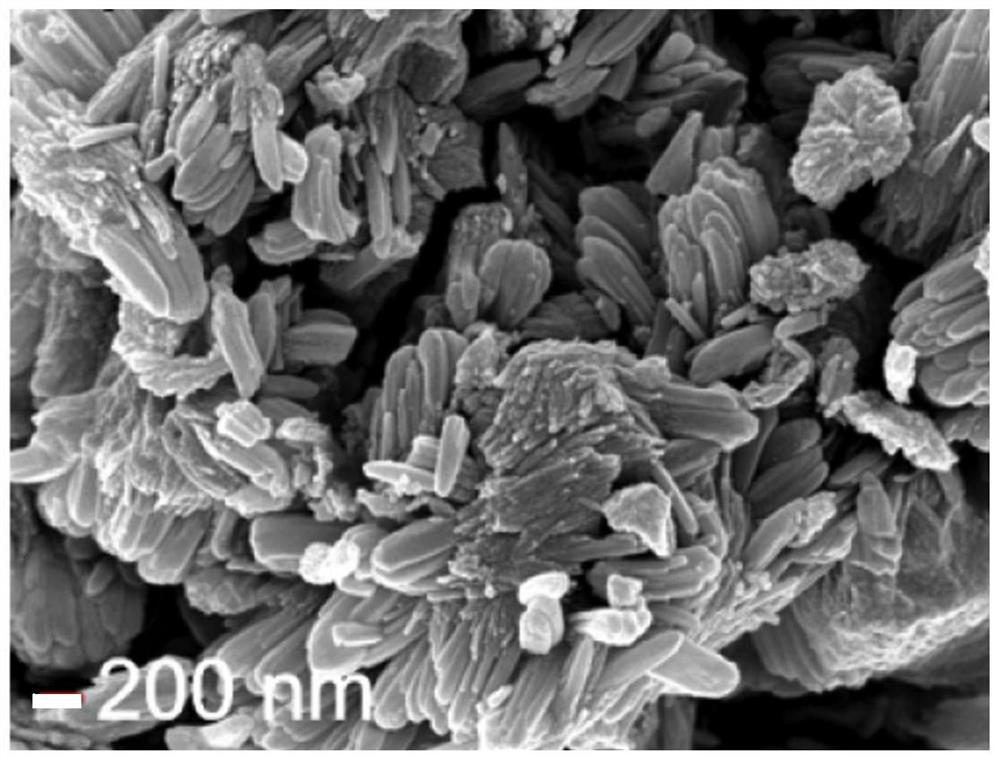

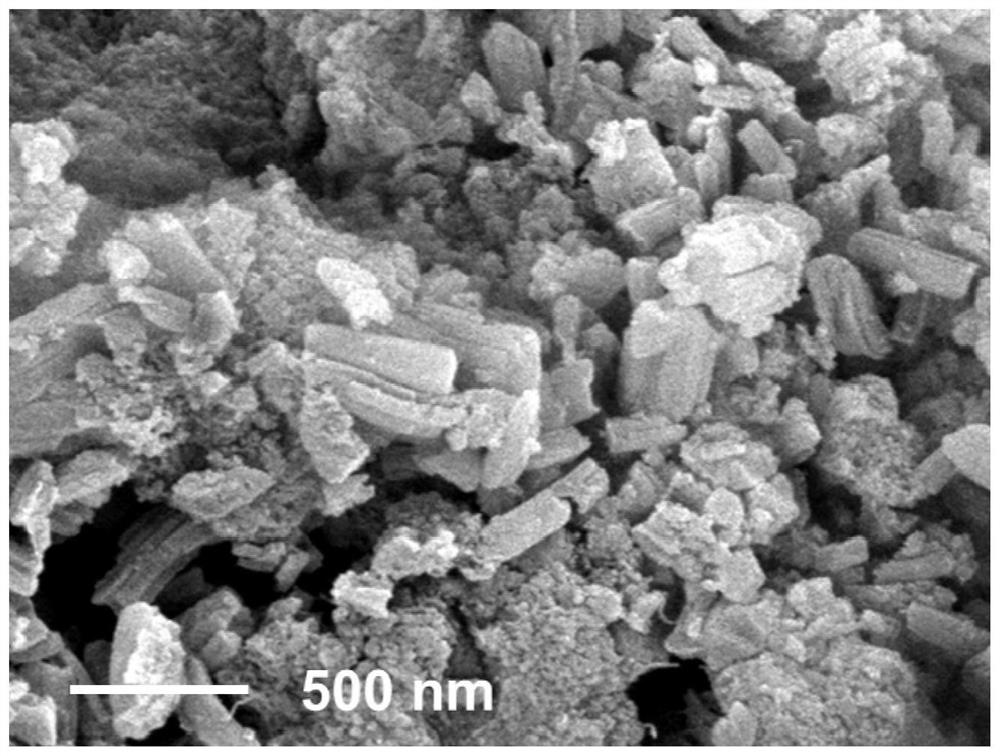

[0050] The aluminum-based MOFs / chitosan composite microspheres prepared by Comparative Example 1, Comparative Example 2 and Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com