A kind of preparation method of microporous cemented carbide material

A cemented carbide and microporous technology, which is applied in the field of preparation of microporous cemented carbide round rods, can solve the problems that round rods are difficult to realize, and achieve the effect of uniform diameter and straight holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

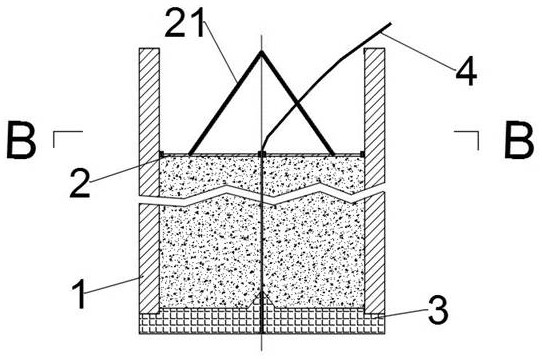

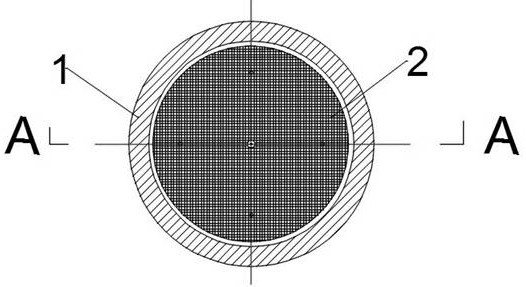

[0027] The present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention.

[0028] as attached Figure 1~2 Shown, a kind of microporous cemented carbide material prepares mold, comprises: mold (1), screen cloth (2), upper plug (not shown in the figure), lower plug (3), soft core rod ( 4); Mold (1): This molding method adopts a dry bag isostatic mold, the mold size is diameter Φ (8.2 ~ 130mm) × length (200 ~ 650mm), and the mold material is rubber, plastic, polyurethane or modified polyurethane Screen cloth (2): screen cloth (2) is made up of screen cloth frame, screen cloth main body and central hole cover, and the outer diameter of screen cloth frame is consistent with die cavity size, and balance pull bar (21) is arranged on the screen cloth frame, guarantees that The screen (2) is pulled upwards smoothly, and the center hole of the screen (2) has a small round hole of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com