Method used for processing methyl orange dye waste water with bean product waste water and waste residue

A technology for soy product wastewater and dye wastewater, which is applied in the directions of oxidized water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as environmental organism damage, reduce environmental damage, and prevent toxic Harmful ingredients, the effect of solving degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

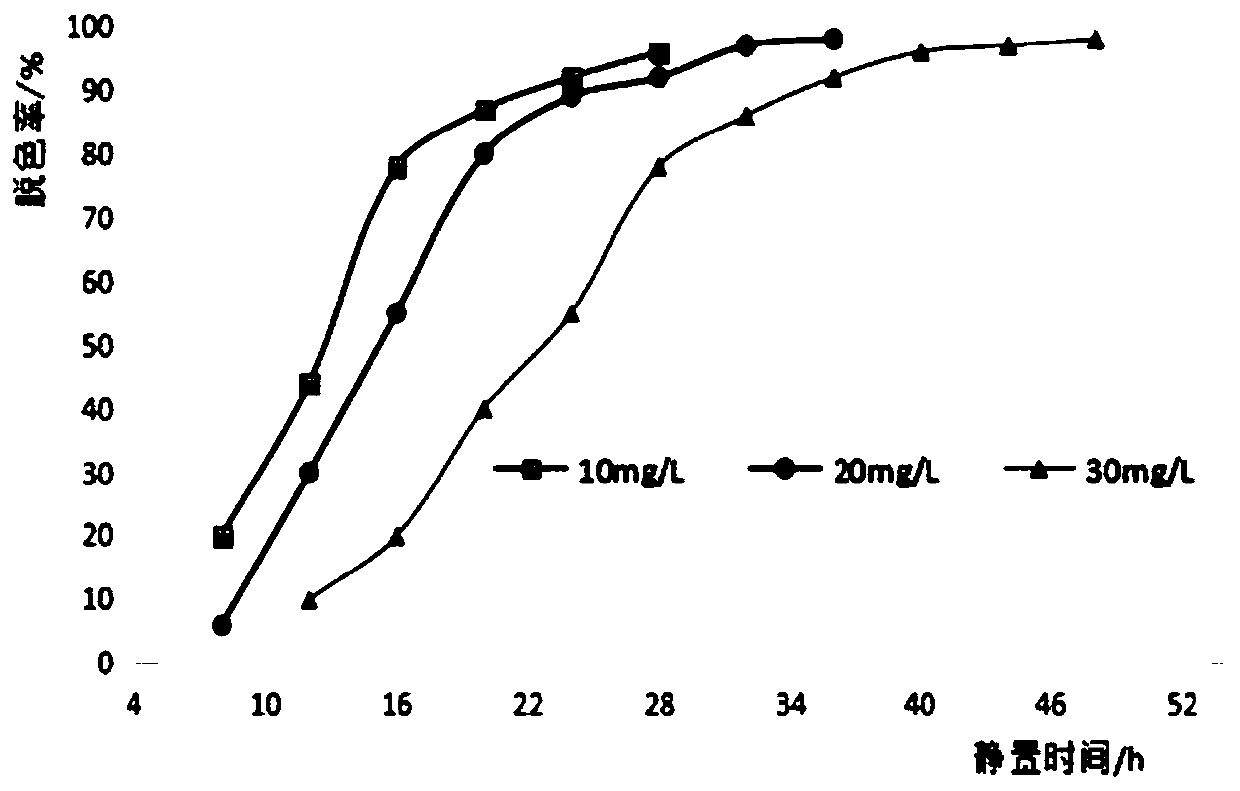

[0027] (1) Take 100mL of fresh yellow pulp water (about pH 6.0) and add it to a beaker, then add methyl orange (the final concentration is 10-30mg / L), shake it well and let it stand for 48 hours with the open mouth at a temperature of 15-30 ℃. At 15°C, its oxidative degradation and fading effect is as follows: figure 1 shown.

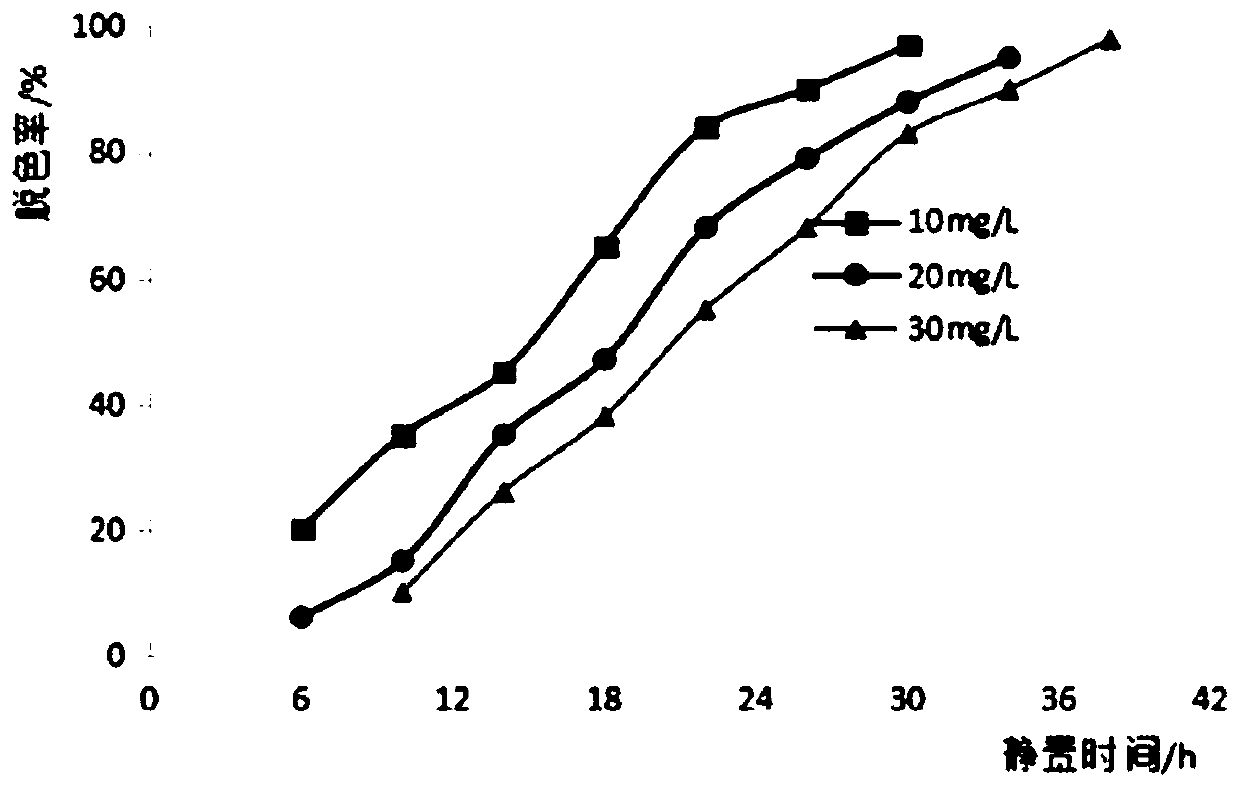

[0028] (2) Take 100mL of fresh yellow pulp water (about pH 6.0) into the beaker, then add methyl orange (the final concentration is 10-30mg / L), shake well, seal and let it stand for 36h at a temperature of 15-30°C , at 15°C, its oxidative degradation and fading effect is as follows figure 2 shown.

Embodiment 2

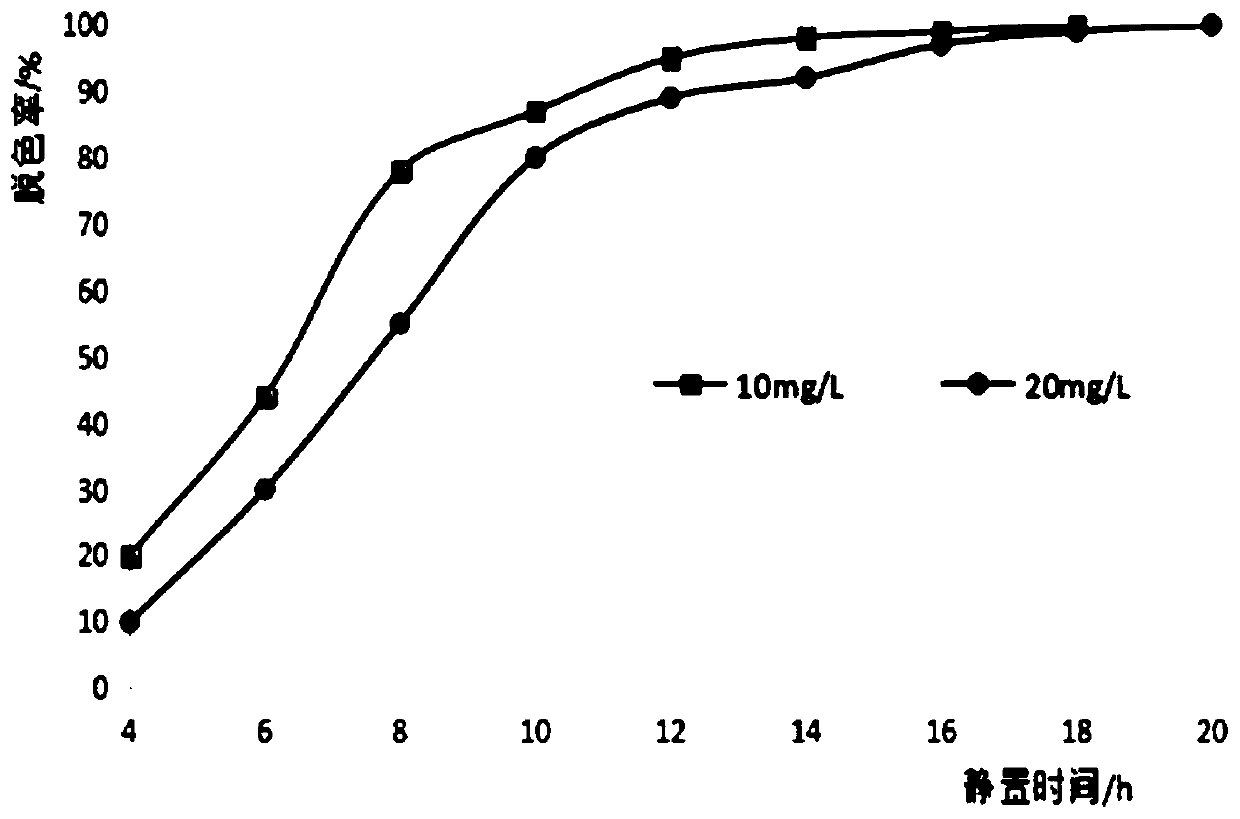

[0030]Take (1) and (2) yellow slurry water that has completely faded, then add methyl orange (the final concentration is 10-20mg / L), shake well and place it at 15-30°C for 20h, at 15°C, Its oxidative degradation and fading effects are as follows: image 3 shown. Repeat 3 to 5 times, the effect is the same.

Embodiment 3

[0032] (1) Take 100mL of yellow slurry water (about pH 4.0) that has been left for 1-3 days and add it to a beaker, add methyl orange (the final concentration is 10-20 mg / L), shake well and place it at 20°C for 16 hours ,Such as Figure 4 shown.

[0033] (2) Take 100mL of yellow pulp water (about pH 4.0) that has been left for 1-3 days and add it to a beaker, add methyl orange (the final concentration is 30mg / L), shake well and place it at 20°C for 28 hours, as Figure 5 shown.

[0034] (3) Take (1) and (2) yellow slurry water that has completely faded, then add methyl orange (the final concentration is 10-30mg / L), shake well and place it at 20-28°C for 6-14h , completely faded, the effect is good, and no abnormal color appears after being placed for a period of time. Can be repeated 3 to 5 times in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com