Extraction method of pseudo-ginseng polysaccharide

A technology of Panax notoginseng polysaccharide and extraction method, which is applied in the field of extraction of Panax notoginseng polysaccharide, can solve the problems of low extraction rate and high impurity content of Panax notoginseng polysaccharide, and achieves the improvement of extraction rate, product quality and high absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

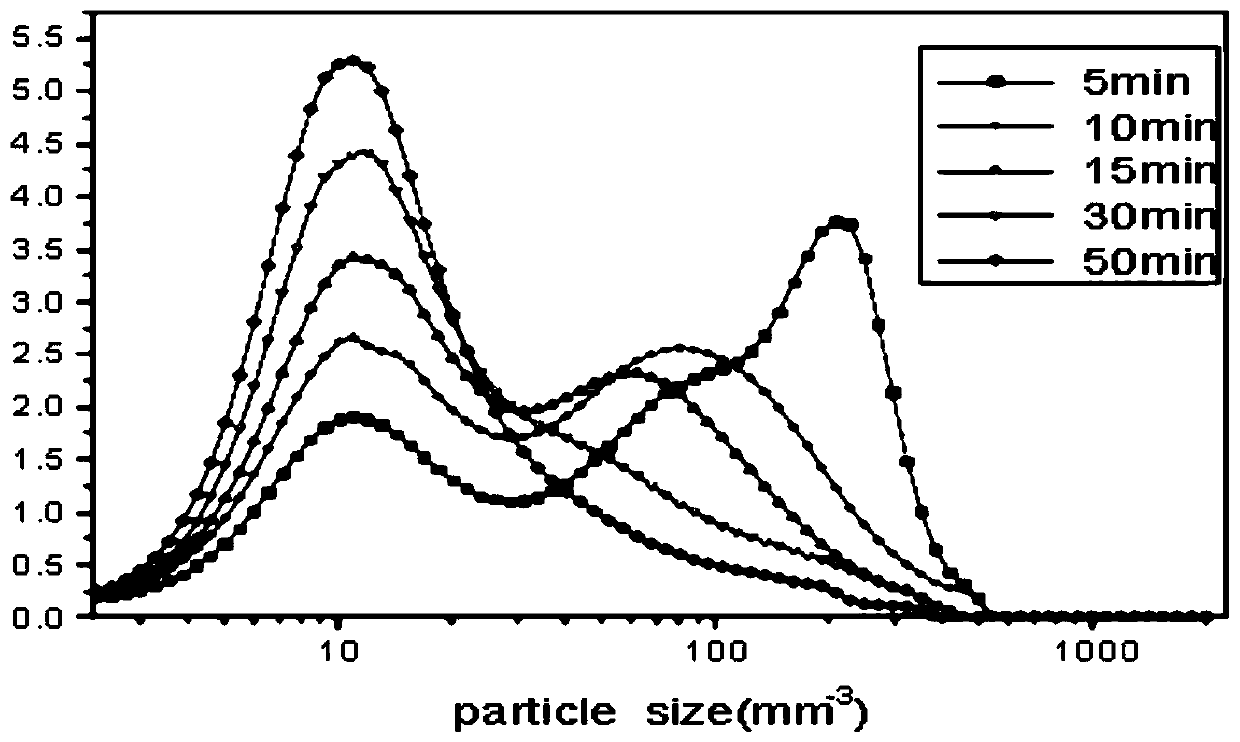

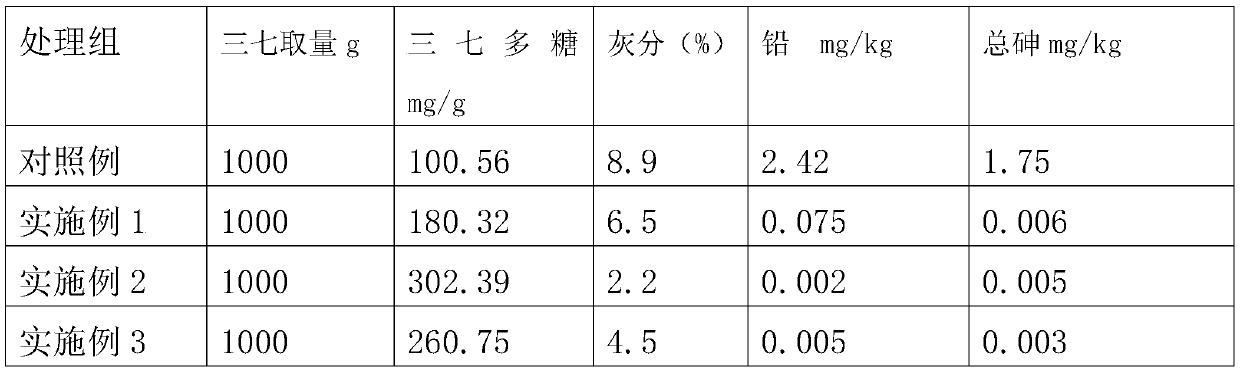

[0024] Take 1000g of Panax notoginseng lump medicinal material, add 30% ethanol, then pour it into a wet micro-powder machine for pulverization, the pulverization time is 8min, then filter and collect the filtrate, the mass of the added ethanol solution is 8 times of that of Panax notoginseng. The collected filtrate is separated by a centrifuge to obtain a centrifuge; the centrifuge is passed through an automatic concentrator to shrink the volume to obtain an extract, and the extract is concentrated under reduced pressure to a Baume degree of 8-10°; after obtaining the extract Add purified water to dissolve it, then add trifluoromethanesulfonic acid with 4% mass of the mixture, and hydrolyze it in airtight at 90°C for 20min, recover trifluoromethanesulfonic acid under vacuum at 45-65°C to obtain crude polysaccharide extract; Cationic resin was added, washed with purified water, and combined to obtain eluates. The mass ratio of cationic resin to polysaccharide crude extract is ...

Embodiment 2

[0026] Take 1000g of Panax notoginseng block medicinal material, add 70% ethanol, then pour it into a wet micro-powder machine for pulverization, the pulverization time is 10min, then filter and collect the filtrate, the mass of the added ethanol solution is 10 times of that of Panax notoginseng. The collected filtrate is separated by a centrifuge to obtain a centrifuge; the centrifuge is passed through an automatic concentrator to shrink the volume to obtain an extract, and the extract is concentrated under reduced pressure to a Baume degree of 9°; in the obtained extract, add Dissolve in purified water, then add trifluoromethanesulfonic acid with 5% mass of the mixture, and hydrolyze in airtight at 90-95°C for 25 minutes, recover trifluoromethanesulfonic acid under vacuum at 45-65°C to obtain crude polysaccharide extract; Cationic resin was added, washed with purified water, and combined to obtain eluates. The mass ratio of cationic resin to polysaccharide crude extract is 3...

Embodiment 3

[0028] Take 1000g of Panax notoginseng block medicinal material, add 90% ethanol, then pour it into a wet micro-powder machine for crushing, the pulverization time is 30min, then filter and collect the filtrate; the mass of the added ethanol solution is 12 times of that of Panax notoginseng. The collected filtrate is separated by a centrifuge to obtain a centrifuge; the centrifuge is passed through an automatic concentrator to shrink the volume to obtain an extract, and the extract is concentrated under reduced pressure to a Baume degree of 10°; in the obtained extract, add Dissolve in purified water, then add trifluoromethanesulfonic acid with 6% mass of the mixture, and after airtight hydrolysis at 90-95°C for 30 minutes, vacuum recover trifluoromethanesulfonic acid at 45-65°C to obtain crude polysaccharide extract; Cationic resin was added, washed with purified water, and combined to obtain eluates. The mass ratio of cationic resin to polysaccharide crude extract is 4:1. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com