Flame retardant and application of flame retardant in thermoplastic polyurethane elastomer flame retardancy

A thermoplastic polyurethane and flame retardant technology, applied in the field of flame retardant thermoplastic polyurethane elastomer modification, can solve the problems of large heat release, dripping dripping, and large amount of flame retardant added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Control the temperature of the internal mixer at 180°C, and the rotational speed is 30 rpm, add thermoplastic polyurethane elastomer with a mass percentage of 90.875% into the internal mixer, and add high-concentration carbon microspheres with a mass percentage of 1.25% after it is melted Thermoplastic polyurethane elastomer masterbatch, melt and blend for 3 minutes, add ammonium polyphosphate with a mass percentage of 7.875%, melt and blend for 10 minutes, take out the composite material and put it in 100×100×3mm 3 In the mould, press into tablets with a flat vulcanizer, control the temperature at 170-180°C, hold the pressure for 10-15 minutes, and cool for 50-60 seconds to obtain the product. Put the sample at 35kW / m 2 The cone calorimeter test was carried out under the radiation power, and the results are shown in Table 1.

Embodiment 2

[0034] The temperature of the internal mixer is controlled at 180°C, the rotating speed is 30 rpm, and the thermoplastic polyurethane elastomer with a mass percentage of 89.75% is added to the internal mixer, and the high-concentration carbon microspheres with a mass percentage of 2.5% are added after it is melted Thermoplastic polyurethane elastomer masterbatch, melt and blend for 3 minutes, add ammonium polyphosphate with a mass percentage of 7.75%, melt and blend for 10 minutes, take out the composite material and put it in 100×100×3mm 3 Press into a tablet with a flat vulcanizing machine, control the temperature at 170-180° C., hold the pressure for 10-15 minutes, and cool for 50-60 seconds to obtain the sample. Put the sample at 35kW / m 2 The cone calorimeter test was carried out under the radiation power, and the results are shown in Table 1.

Embodiment 3

[0036] The temperature of the internal mixer is controlled at 180°C, the rotating speed is 30 rpm, and 83% by mass of thermoplastic polyurethane elastomer is added to the internal mixer, and after it is melted, 10% by mass of high-concentration carbon microspheres are added Thermoplastic polyurethane elastomer masterbatch, melt and blend for 3 minutes, add ammonium polyphosphate with a mass percentage of 7%, melt and blend for 10 minutes, take out the composite material and put it in 100×100×3mm 3 Press into a tablet with a flat vulcanizing machine, control the temperature at 170-180° C., hold the pressure for 10-15 minutes, and cool for 50-60 seconds to obtain the sample. Put the sample at 35kW / m 2 The cone calorimeter test was carried out under the radiation power, and the results are shown in Table 1.

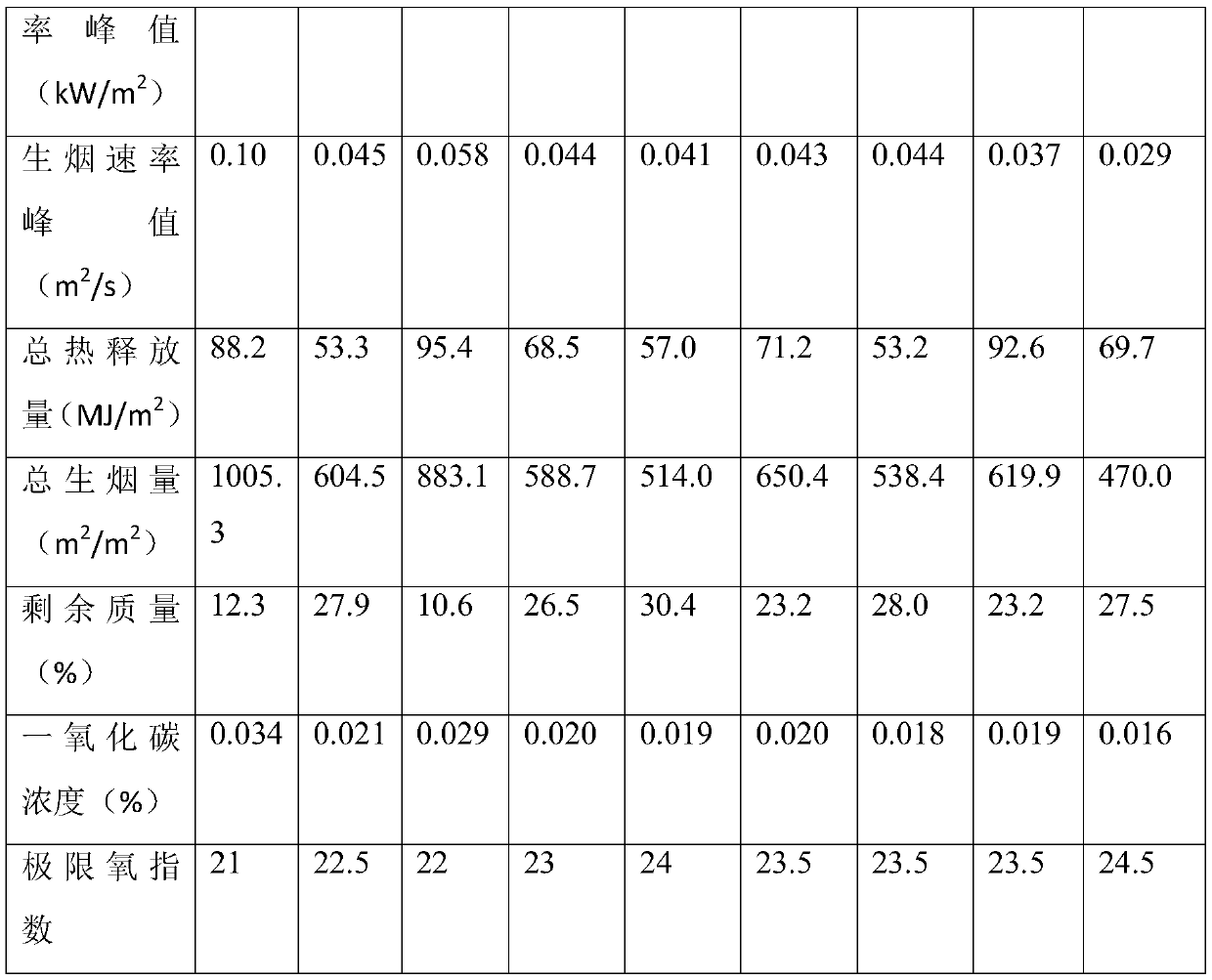

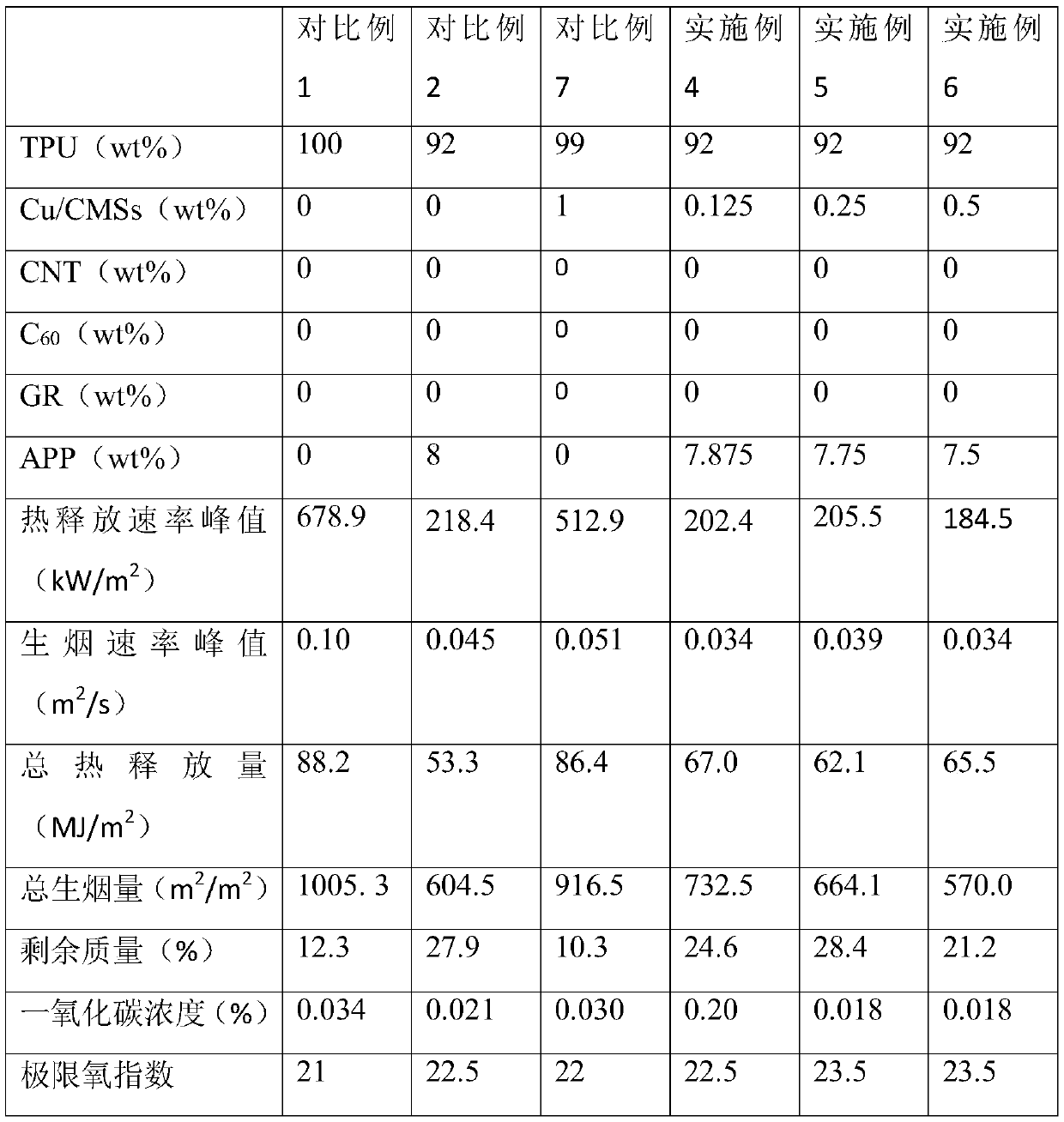

[0037] Table 1 Flame-retardant thermoplastic polyurethane elastomer composite material performance table-1 of the present invention

[0038]

[0039]

[0040] It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com