Cardanol modified nitrile-based phenolic resin adhesive and preparation method thereof

The technology of cardanol nitrile-based resin and nitrile-based phenolic resin is applied in the field of cardanol-modified nitrile-based phenolic resin adhesive and its preparation, and can solve the problems of poor process performance, low bonding strength, and high brittleness of phenolic resin. , to achieve the effect of improving processing performance and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

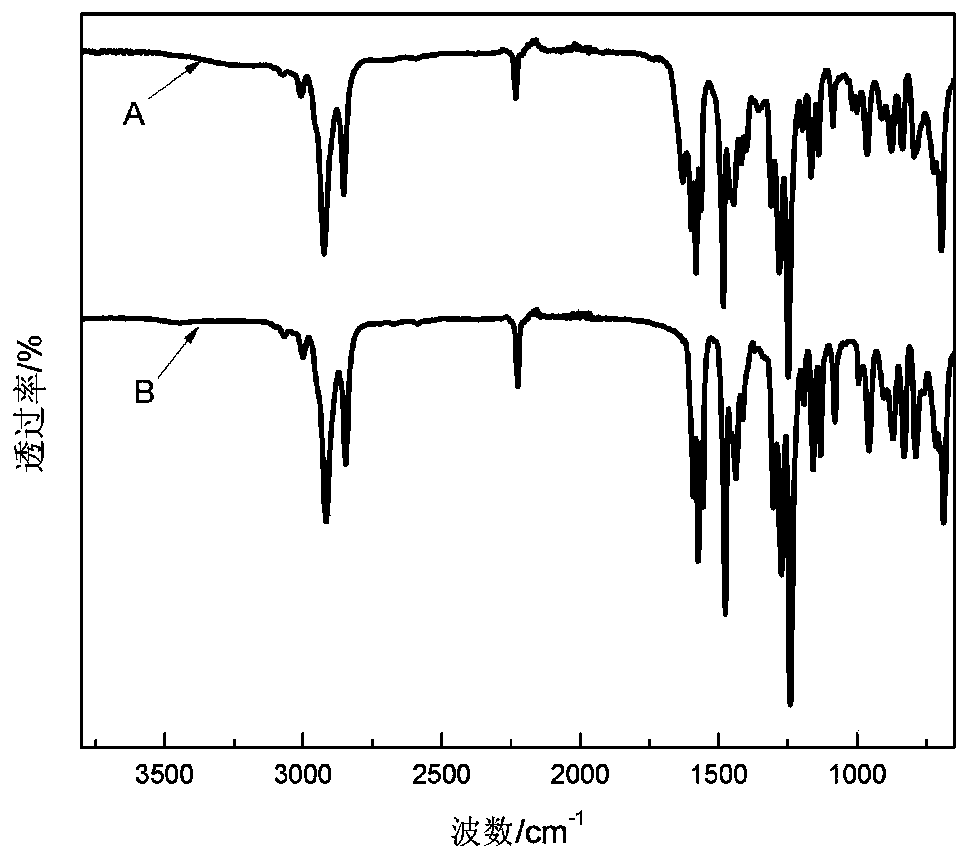

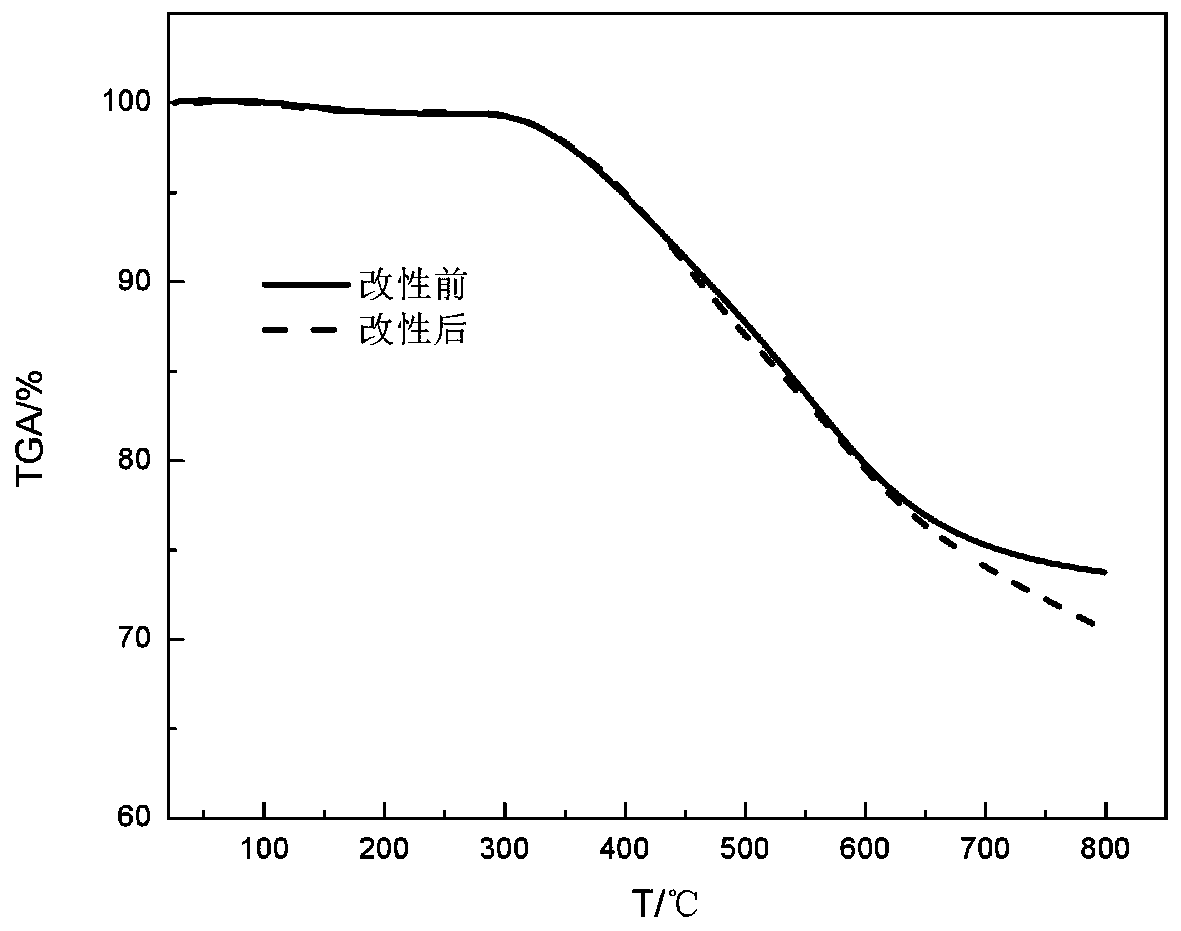

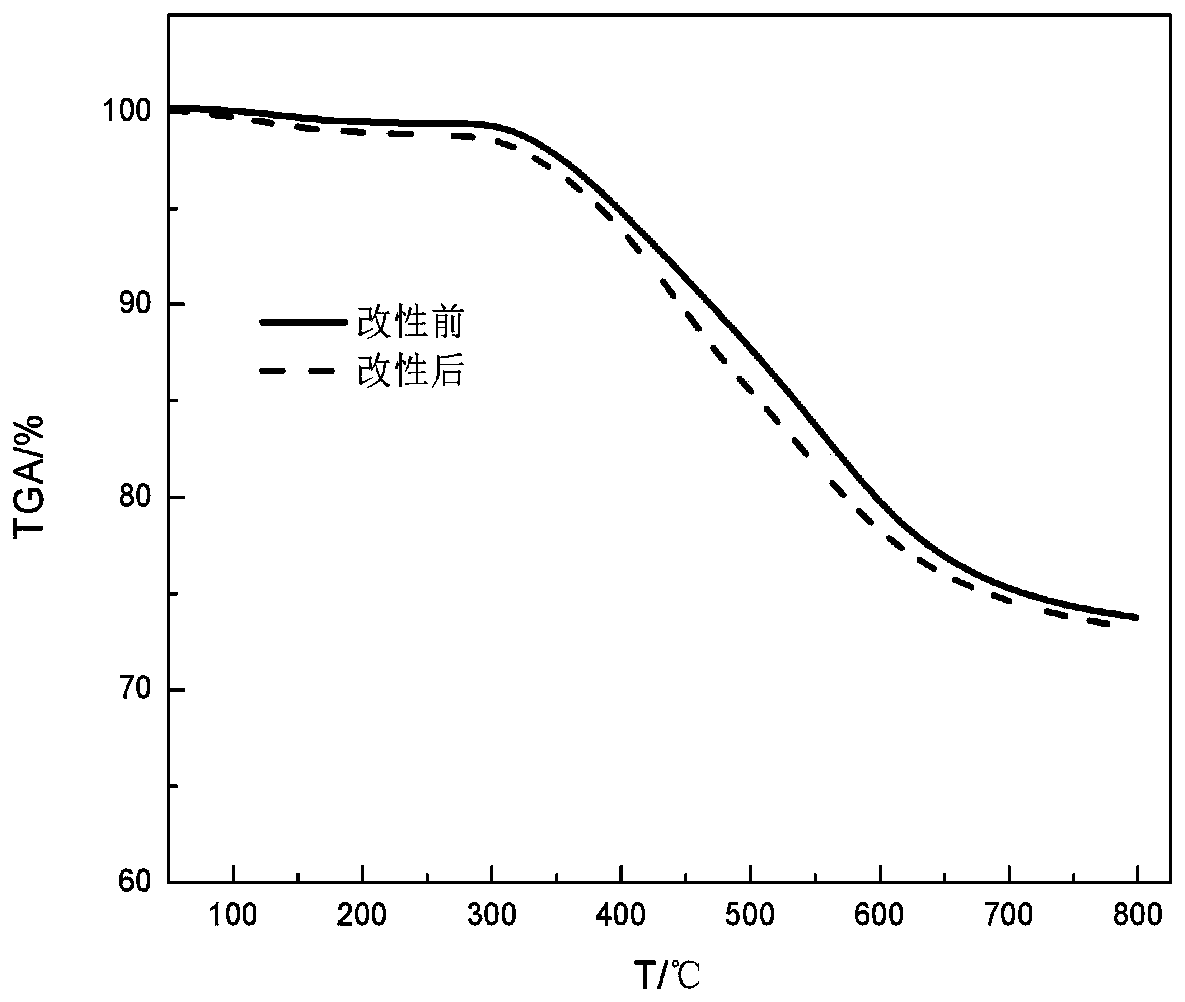

Method used

Image

Examples

Embodiment 1

[0036] A cardanol-modified nitrile-based phenolic resin adhesive, comprising the following components in parts by mass: 100 parts of nitrile-based phenolic resin and 2.5-50 parts of cardanol-based nitrile-based resin.

Embodiment 2

[0038] A cardanol-modified nitrile-based phenolic resin adhesive, comprising the following components in parts by mass: 100 parts of nitrile-based phenolic resin and 2.5 to 50 parts of cardanol-based nitrile-based resin, wherein the structural formula of the cardanol-based phenolic-based resin is:

[0039]

[0040] where R=C 15 h 32-n .

[0041] The viscosity of the cardanol nitrile resin used in the present embodiment at 25°C is not more than 600mPa·s,

Embodiment 3

[0043] The present embodiment provides a kind of preparation method of cardanol modified nitrile phenolic resin adhesive, comprises the steps:

[0044] Step 1, prepare cardanol nitrile-based resin:

[0045] Weigh cardanol and nitro-substituted phthalonitrile according to a certain molar ratio and put it into an organic solvent, fully stir to obtain a uniform mixed solution, add a certain amount of basic catalyst to the mixed solution, and make the reaction system Stirring at a certain temperature while reacting for a certain period of time, after the reaction is completed, the resulting product is cooled to room temperature, allowed to stand for stratification, and the upper layer liquid is collected, washed with water, extracted with a solvent, and distilled under reduced pressure to obtain a cardanol nitrile-based resin;

[0046] Step 2, prepare phenolic resin:

[0047] Mix phenol and formaldehyde evenly in a certain molar ratio, add catalyst a at a certain reaction tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Room temperature shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com