Oilfield modular processing system

A processing system and modular technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of low integration, difficulty in complete set of process equipment, small scale of equipment, etc., to overcome the incomplete complete set, safe operation, manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

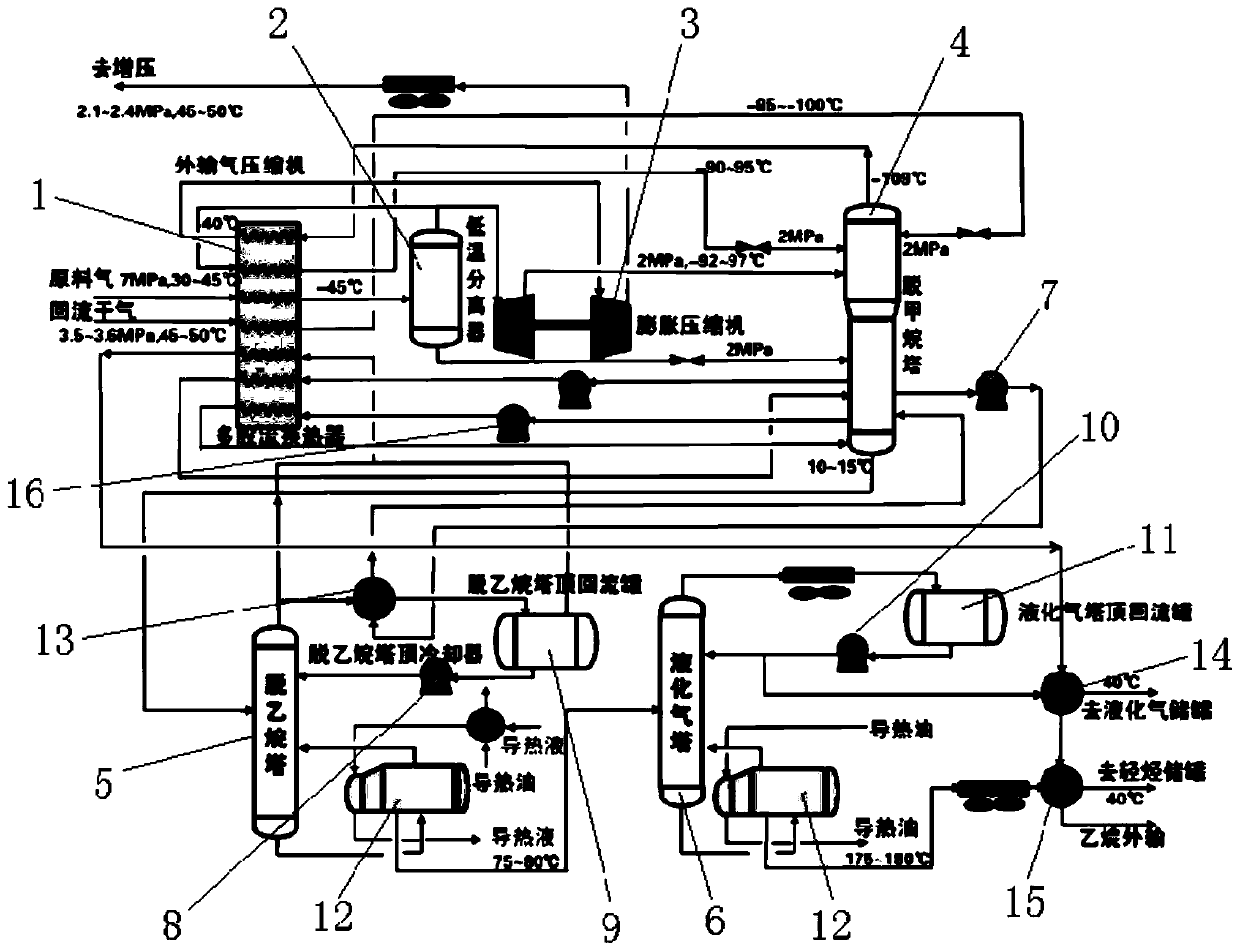

[0015] like figure 1 As shown, an oilfield modular treatment system includes a rectification skid, a cryogenic dehydrogenation skid, and a molecular sieve dehydration skid. The cryogenic dehydrocarbon skid is mainly divided into three areas: the low temperature area, the tower area, and the reflux tank reflux pump area. Among them, the low temperature zone mainly has multi-stream heat exchanger 1 , low temperature separator 2 and expansion compressor 3 . The tower area consists of a demethanizer 4, a deethanizer 5, and a liquefied gas tower 6 to form a combined tower platform. The demethanizer side line pump 7, the deethanizer reflux pump 8, the deethanizer top reflux tank 9, the liquefied gas tower reflux pump 10, and the liquefied gas tower top reflux tank 11 form the reflux tank reflux pump area. The multi-stream heat exchanger 1 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com