Cornus officinalis and aronia melanocarpa composite fruit vinegar and preparation method thereof

A technology of dogwood and rowan, applied in the field of compound fruit vinegar of dogwood and black fruit rowan and its preparation, can solve the problems of preparing fruit vinegar from black fruit rowan, which can improve process parameters, lower blood pressure, The effect of lowering the extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

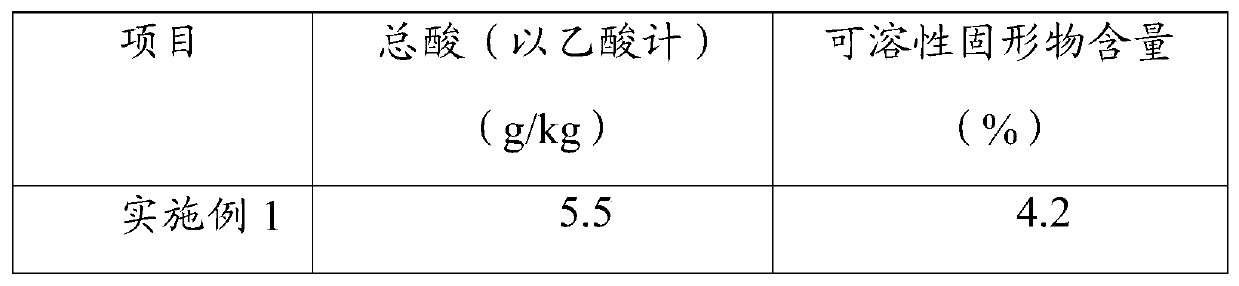

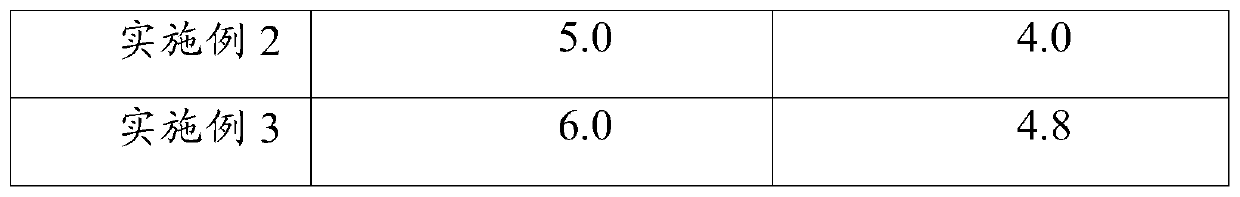

Examples

Embodiment 1

[0047] A compound fruit vinegar product and preparation method of dogwood black berry rowan, the specific steps are as follows:

[0048] S1, Cornus officinalis

[0049] Select 100kg of dry fruit of Cornus officinalis produced in the year, crush it with a pulverizer, spray and mix well with 500mL of 35% edible alcohol, and store it sealed at room temperature for 48 hours to complete the deastringency;

[0050] S2, enzymatic hydrolysis and extraction of Cornus officinalis

[0051] Add clear water to the deastringent Cornus officinalis according to the material-to-liquid ratio of 1kg:12L, heat to 45°C, add cellulase with a mass fraction of 0.4%, and incubate for 3h, and stir once every 0.5h during this period to obtain an extract;

[0052] S3, preparation of dogwood juice

[0053] Filtrate the extract obtained by S2 while it is hot, collect the filtrate, and cool to normal temperature to obtain Cornus officinalis juice;

[0054] S4, preparation of rowan pulp

[0055] Select f...

Embodiment 2

[0071] A compound fruit vinegar product and preparation method of dogwood black berry rowan, the specific steps are as follows:

[0072] S1, Cornus officinalis

[0073] Select 100kg of dry fruit of Cornus officinalis produced in the year, crush it with a pulverizer, spray it with 450mL of 38% edible alcohol, mix well, and store it sealed at room temperature for 40 hours to complete the deastringency;

[0074] S2, enzymatic hydrolysis and extraction of Cornus officinalis

[0075] Add clear water to the deastringent Cornus officinalis according to the material-to-liquid ratio of 1kg:15L, heat to 48°C, add cellulase with a mass fraction of 0.3% and incubate for 2.5h, and stir once every 0.5h during this period to obtain an extract;

[0076] S3, preparation of dogwood juice

[0077] Filtrate the extract obtained by S2 while it is hot, collect the filtrate, and cool to normal temperature to obtain Cornus officinalis juice;

[0078] S4, preparation of rowan pulp

[0079] Select ...

Embodiment 3

[0095] A compound fruit vinegar product and preparation method of dogwood black berry rowan, the specific steps are as follows:

[0096] S1, Cornus officinalis

[0097] Select 100kg of dry fruit of Cornus officinalis produced in the year, crush it with a crusher, spray it with 550mL of 32% edible alcohol, mix well, and store it sealed at room temperature for 42 hours to complete the astringency removal;

[0098] S2, enzymatic hydrolysis and extraction of Cornus officinalis

[0099] Add clear water to the deastringent Cornus officinalis according to the material-to-liquid ratio of 1kg:18L, heat to 42°C, add cellulase with a mass fraction of 0.5% and incubate for 3.5h, and stir once every 0.5h during this period to obtain an extract;

[0100] S3, preparation of dogwood juice

[0101] Filtrate the extract obtained by S2 while it is hot, collect the filtrate, and cool to normal temperature to obtain Cornus officinalis juice;

[0102] S4, preparation of rowan pulp

[0103] Sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com