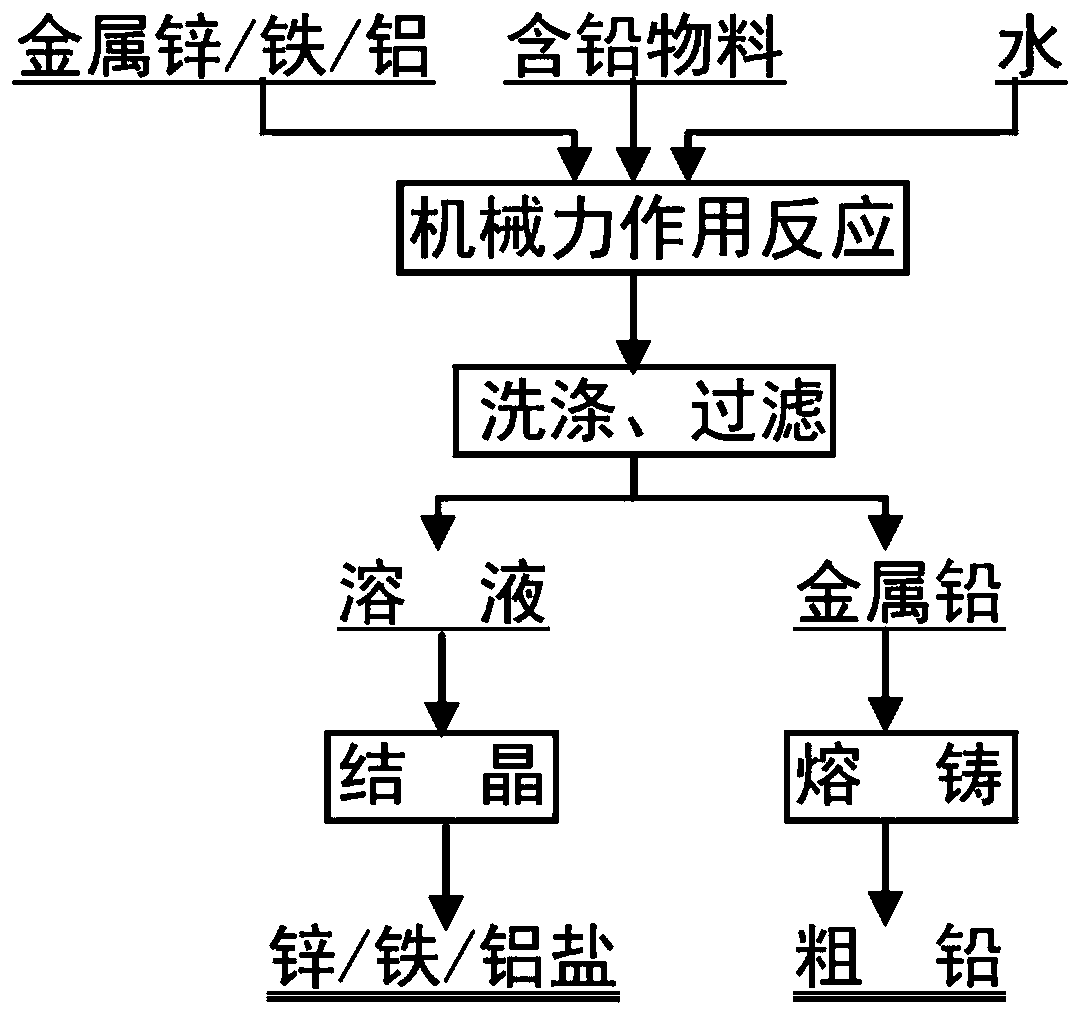

A method for directly preparing metallic lead from lead-containing materials by solid phase reaction

A technology of solid phase reaction and metal lead, applied in the field of hydrometallurgy, can solve the problems of limited raw material processing capacity, occupying more land resources, and long process flow, etc., and achieves low reagent cost, simple process flow, and large processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

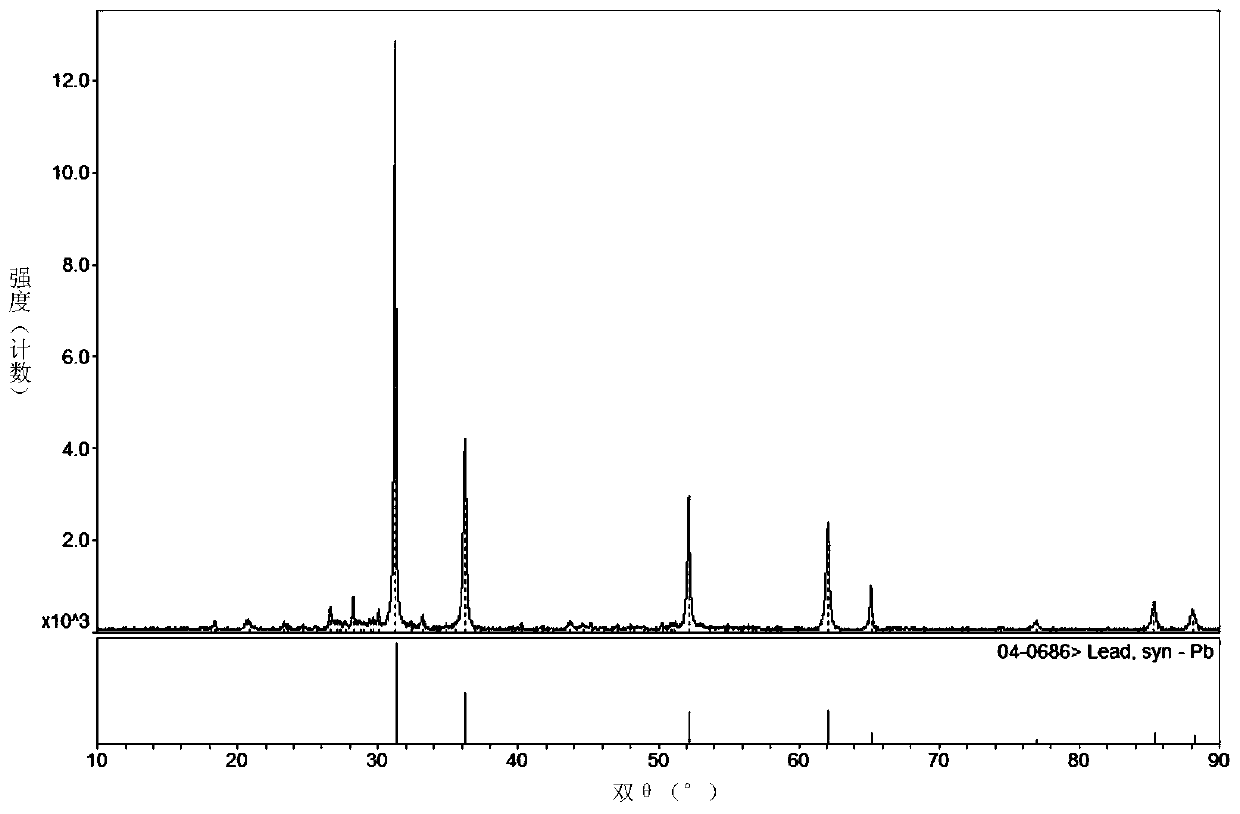

Embodiment 1

[0040] Solid phase reaction: 1kg of lead paste (Pb 70.8%), the amount of zinc powder is 1.0 times the theoretical amount, the reaction equipment is a stirring mill, the weight ratio of ball to material is 2:1, and the ratio of water to material is 0.3:1 (m 3 / t), add sulfuric acid to control the reaction pH3.0, the reaction time is 0.2h, and the lead conversion rate reaches 98.8%.

[0041] Solid-liquid separation: Wash and filter the solid-phase reaction product to obtain metallic lead and zinc sulfate solutions.

[0042] Metal lead melting and casting: the melting and casting temperature is 600°C, the amount of coal is 2.5%, and the obtained crude lead contains 99.1% lead. Crystallization: crystallize the zinc sulfate solution to obtain the zinc sulfate product.

Embodiment 2

[0044] Solid phase reaction: 1kg of lead paste (Pb 70.8%), the amount of zinc particles is 1.0 times the theoretical amount, the reaction equipment is a ball mill, the weight ratio of ball to material is 12:1, and the ratio of water to material is 1:1 (m 3 / t), add sulfuric acid to control the reaction pH to 4.0, the reaction time is 1h, and the lead conversion rate reaches 97.8%.

[0045] Solid-liquid separation: Wash and filter the solid-phase reaction product to obtain metallic lead and zinc sulfate solutions.

[0046] Metal lead melting and casting: the melting and casting temperature is 600°C, the coal consumption is 2.5%, and the crude lead obtained contains 98.1% lead. Crystallization: crystallize the zinc sulfate solution to obtain the zinc sulfate product.

Embodiment 3

[0048] Solid phase reaction: 1kg of lead paste (Pb 70.8%), the amount of iron filings is 1.0 times the theoretical amount, the reaction equipment is a stirring mill, the weight ratio of ball to material is 10:1, and the ratio of water to material is 0.5:1 (m 3 / t), add sulfuric acid to control the reaction pH to 3.0, the reaction time is 1h, and the lead conversion rate reaches 97.6%.

[0049] Solid-liquid separation: wash and filter the solid-phase reaction product to obtain metallic lead and ferrous sulfate solution.

[0050] Metal lead melting and casting: the melting and casting temperature is 570°C, the amount of coal is 2%, and the obtained crude lead contains 98.9% lead. Crystallization: Crystallize the ferrous sulfate solution to obtain the ferrous sulfate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com