Cabin type refrigerating machine room and construction method thereof

A refrigeration machine room and refrigeration machine technology, applied in heating methods, industrial buildings, household heating, etc., can solve the problems of unguaranteed quality and construction period, hidden safety hazards, and high labor consumption, so as to reduce the difficulty of assembly and improve safety Sexuality, the effect of reducing the number of pipe fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

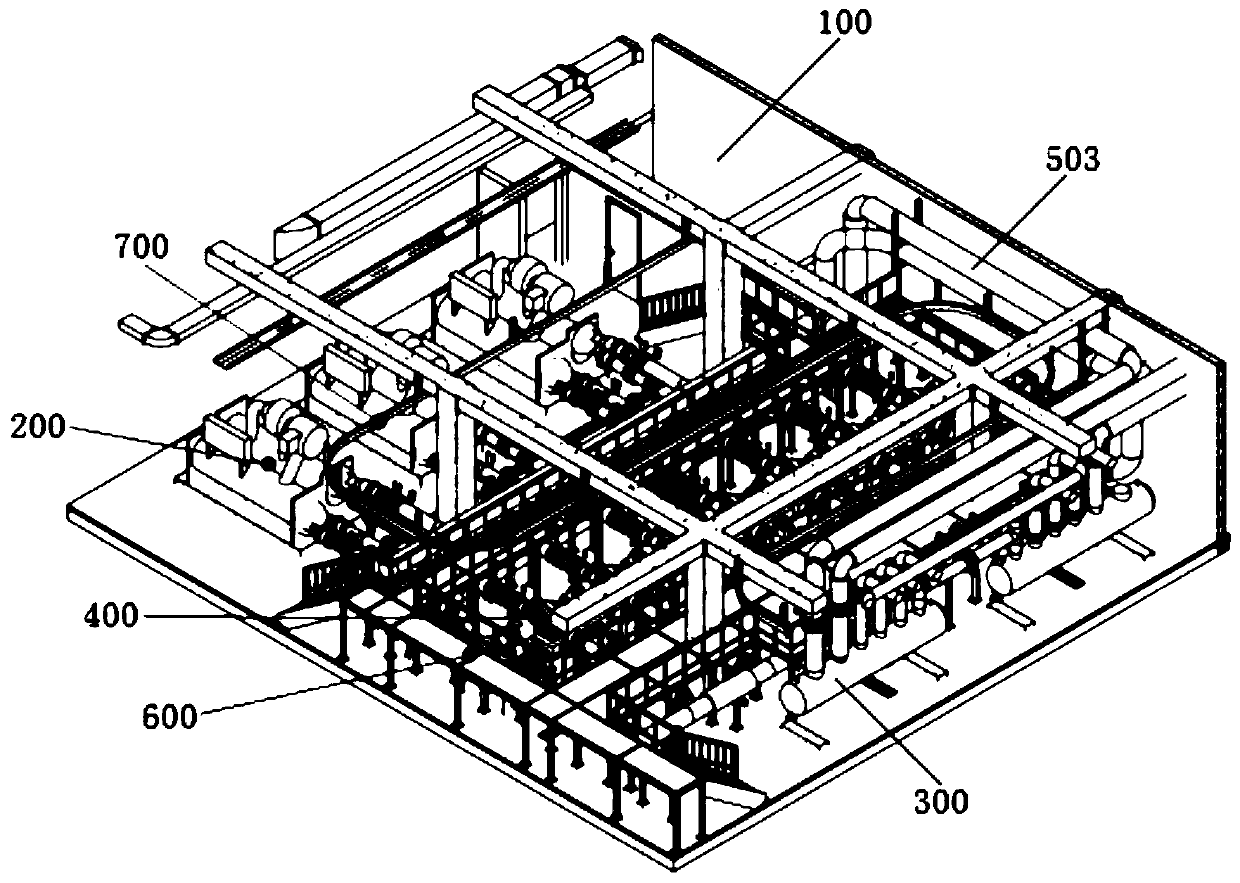

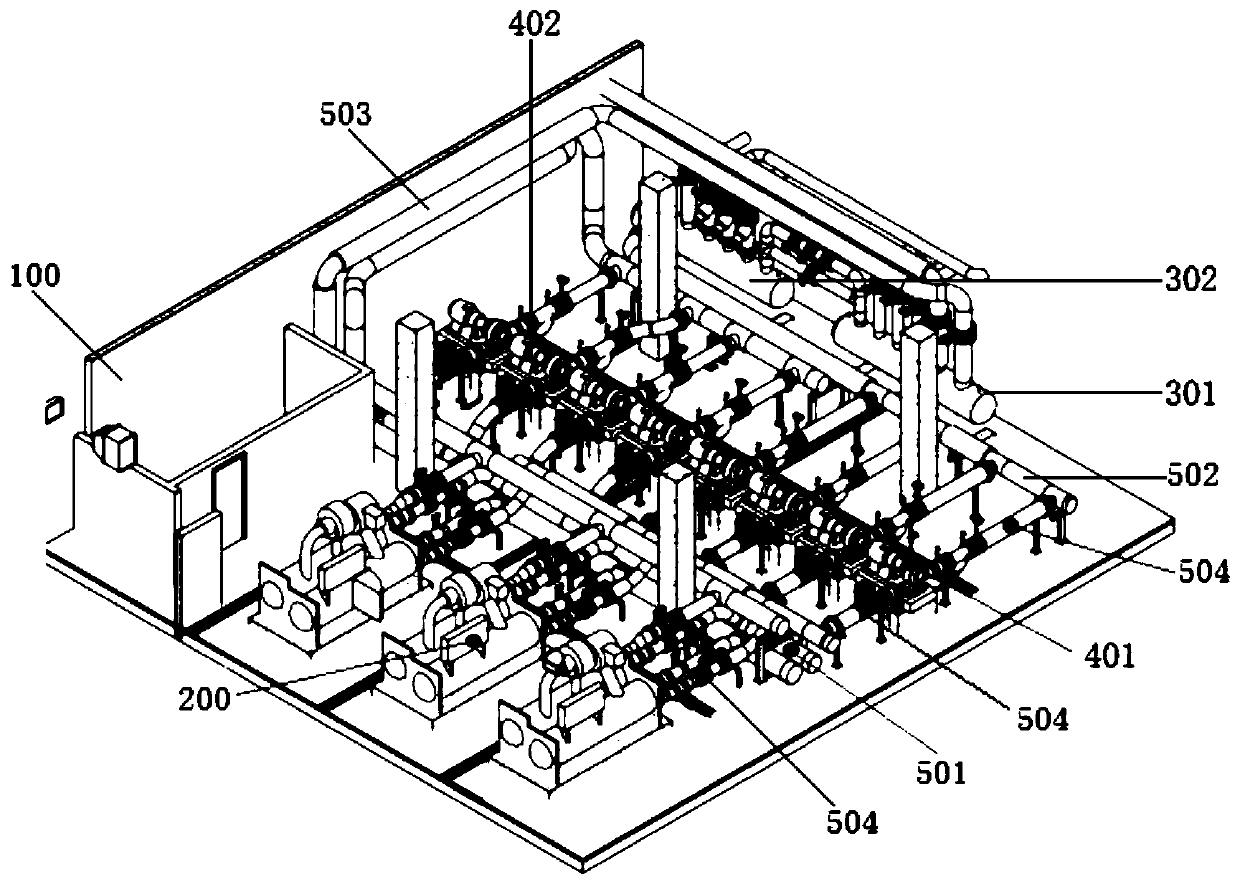

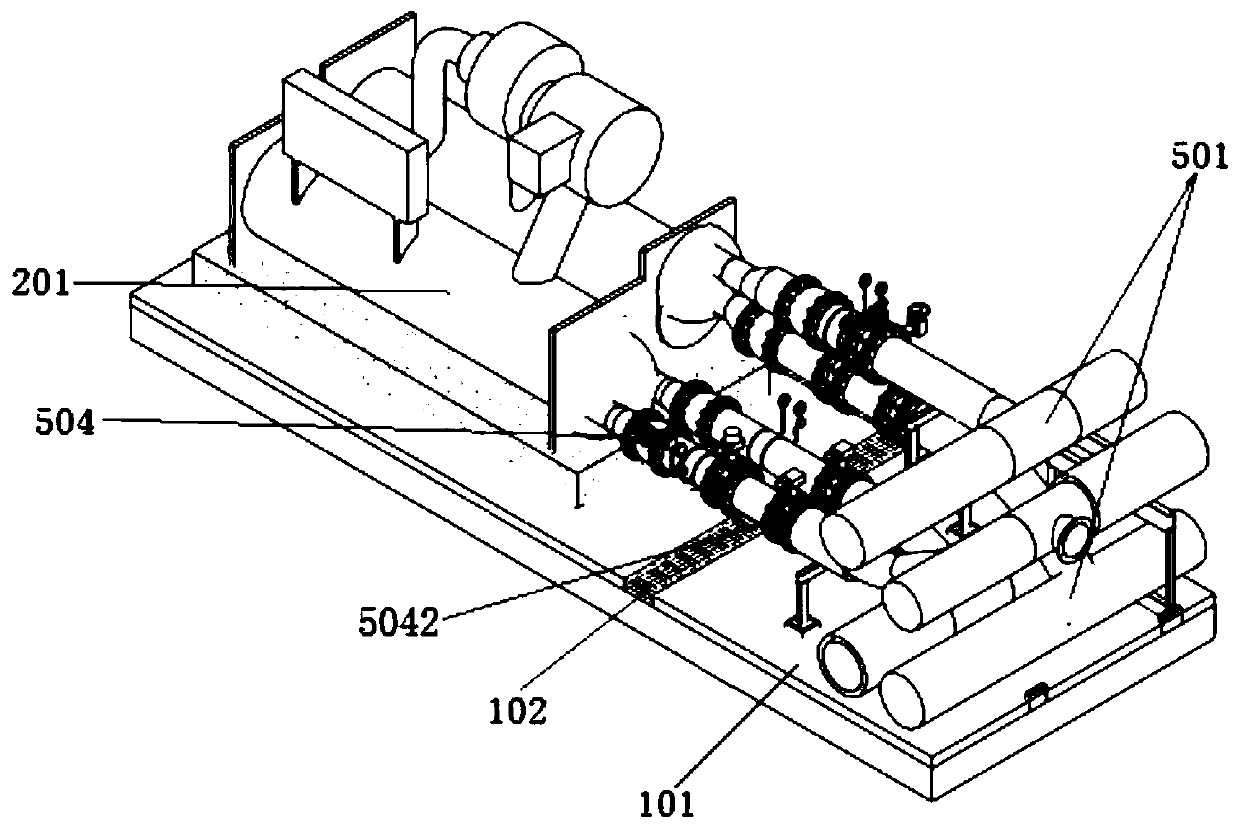

[0041] Such as figure 1 and figure 2 , the embodiment of the present invention provides a cabin type refrigerator room, including a room body 100, a plurality of refrigerators 201, a plurality of chilled water pumps 401 and a plurality of cooling water pumps 402 are arranged on the floor 101 of the room body, and the floor of the room body Ground layer chilled water pipelines and ground layer cooling water pipelines are also arranged on 101, the chilled water piping system of the refrigerator 201 and the chilled water piping system of the chilled water pump 401 are respectively communicated with the ground layer chilled water pipelines through the adapter pipe 504 , the cooling water piping system of the refrigerator 201 and the cooling water piping system of the cooling water pump 402 are respectively communicated with the ground layer cooling water piping through the adapter pipe 504 .

[0042] Conventionally, a water separator 300 is arranged inside the house body 100 , w...

Embodiment 2

[0062] This embodiment relates to the construction method of the cabin-type refrigerator room provided in the first embodiment above, including the following steps:

[0063] Step 1: Create the structural model of the refrigeration machine room and the structural model of the maintenance platform;

[0064] Step 2: According to the structural models created in Step 1, perform assembly design on the maintenance platform 600 and the water pipes in the machine room to obtain the machine room assembly plan;

[0065] Step 3: Off-site prefabrication of the water pipes in the machine room and the maintenance platform structural parts;

[0066] Step 4: According to the machine room assembly scheme obtained in Step 2, complete on-site assembly in the room body 100, wherein the cooling water and / or chilled water pipes between the sub-collectors 300, each of the refrigerators 201 and each of the water pumps 400 are connected All are carried out on the body floor 101.

[0067] Further, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com