TSV-based accumulative MOS variable-capacitance diode and preparation method thereof

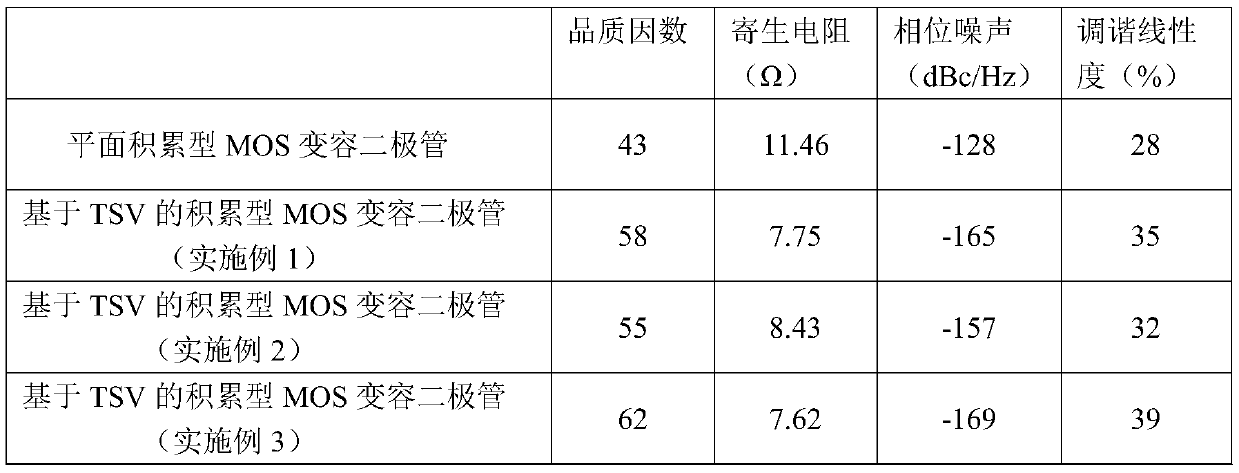

A varactor diode, accumulation-type technology, applied in semiconductor/solid-state device manufacturing, advanced technology, electrical components, etc., can solve problems such as large signal loss, and achieve high quality factor, no signal loss, and low phase noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

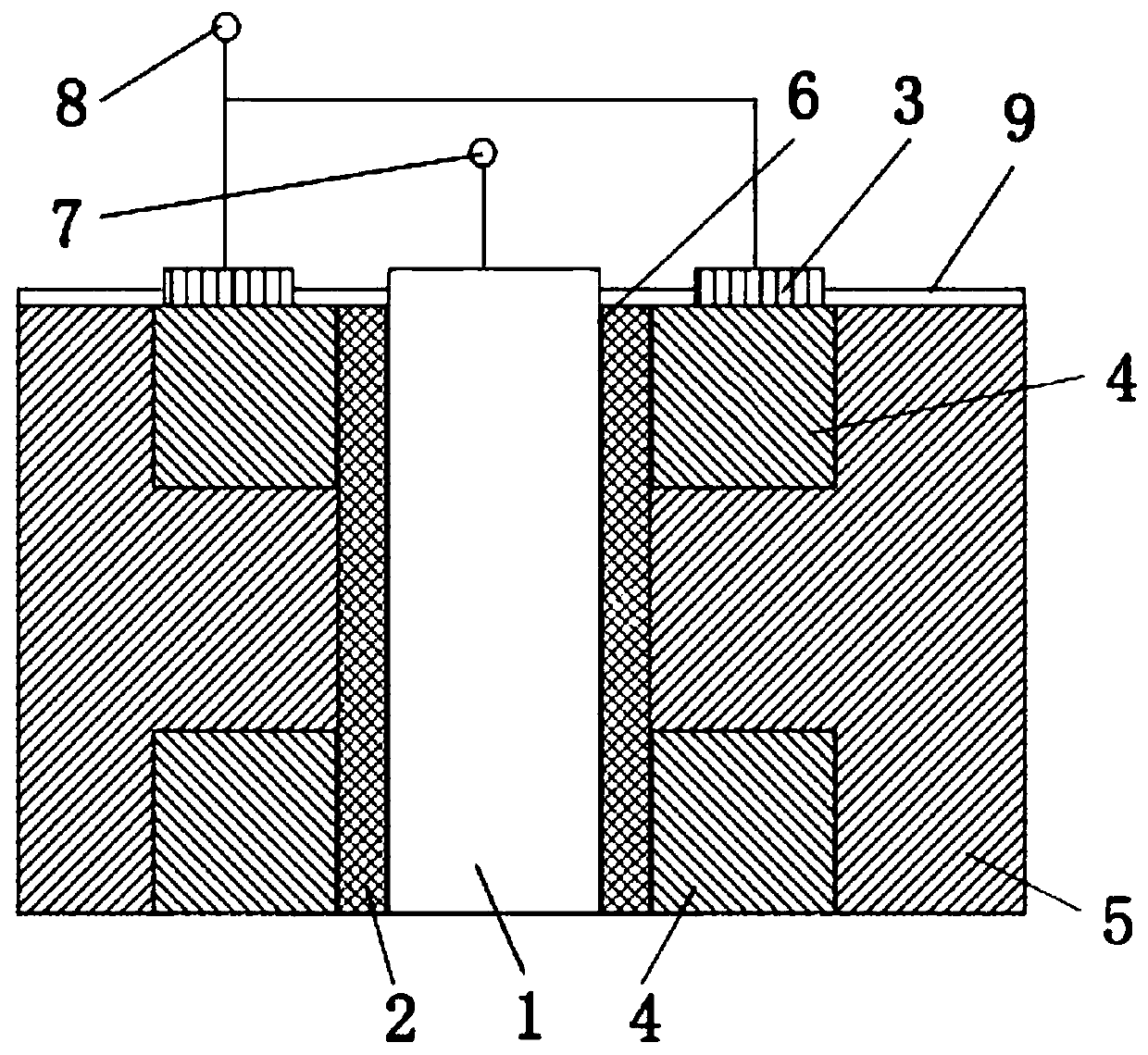

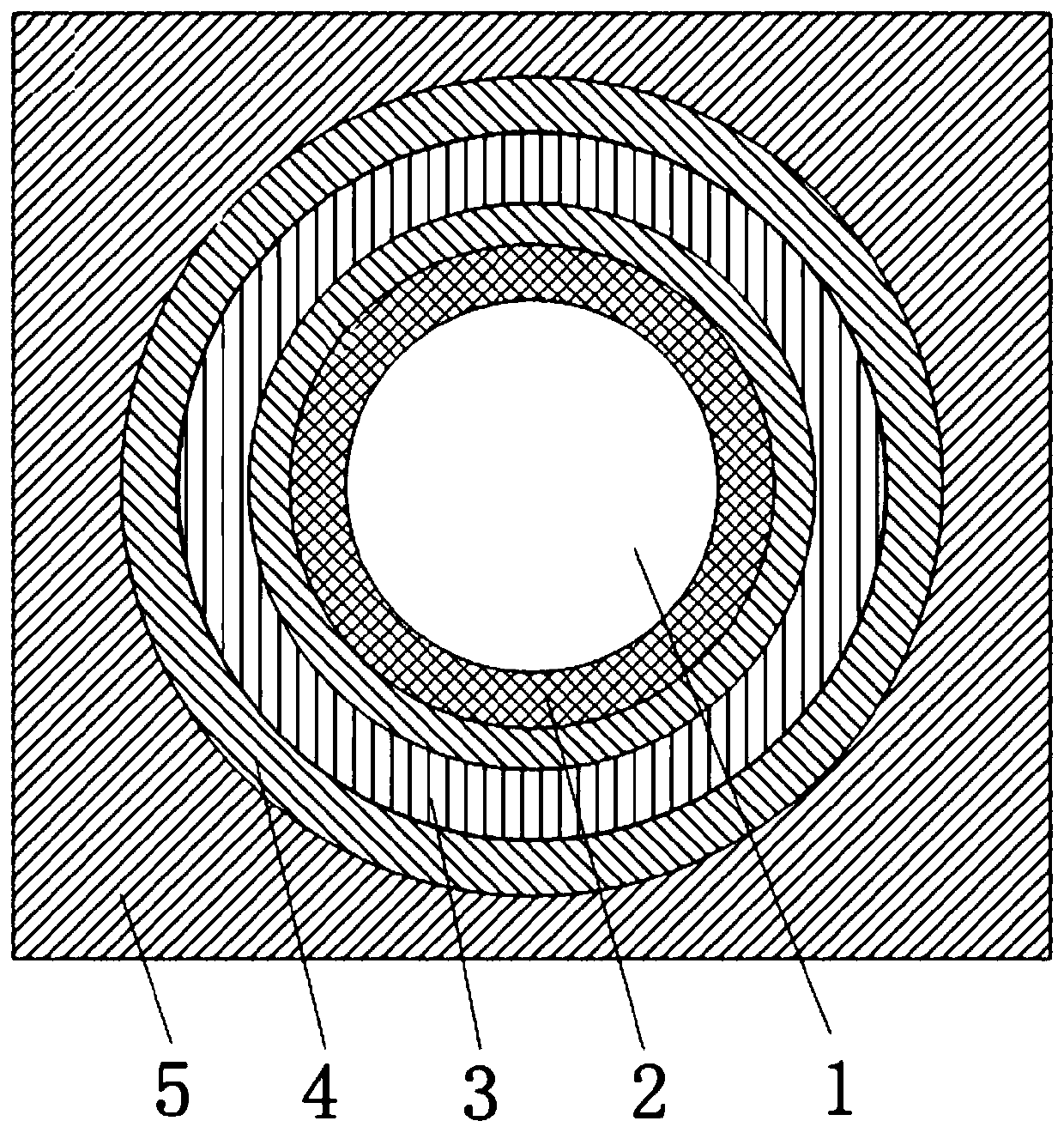

[0033] A kind of preparation method of the accumulation type MOS varactor diode based on TSV of the present invention, comprises the following steps:

[0034] Step 1: Etch vertical through-holes 6 on the P-type silicon substrate 5 by means of reactive ions; use fluoride or chloride reactive gases to decompose fluorine atoms or chlorine atoms in glow discharge, and connect with the silicon substrate The silicon atoms on the surface of the bottom 5 react to form gaseous products to complete the etching of the vertical through hole 6; the pressure of the reaction gas is 14-31Pa, the flow rate of the reaction gas is 11-42 ml / min, and the radio frequency power range is 210-360W; During the process, heat exchangers and helium cooling technology are used to control the temperature of the silicon substrate to ensure that the temperature of the entire silicon substrate 5 during the etching process is uniform and stable at about 145°C.

[0035] Step 2, prepare the dielectric layer 2 on ...

Embodiment 1

[0041] The preparation of a TSV-based accumulation MOS varactor diode specifically includes the following steps:

[0042] Step 1: Etch vertical through-holes 6 on the P-type silicon substrate 5 by means of reactive ions; use chloride reactive gas to decompose chlorine atoms in glow discharge, and silicon atoms on the surface of the silicon substrate 5 The reaction generates gaseous products to complete the etching of the vertical through hole 6; the reaction gas pressure is 14Pa, the reaction gas flow rate is 16 ml / min, and the radio frequency power range is 260W; during the etching process, heat exchanger and helium cooling technology are used Control the temperature of the silicon substrate to ensure that the temperature of the entire silicon substrate 5 during the etching process is uniform and stable at about 145°C;

[0043] Step 2, on the inner wall of the through hole 6, an annular dielectric layer 2 is prepared by the atmospheric pressure chemical vapor deposition metho...

Embodiment 2

[0050] The preparation of a TSV-based accumulation MOS varactor diode specifically includes the following steps:

[0051] Step 1: Etch vertical through holes 6 on the P-type silicon substrate 5 by means of reactive ions; use fluoride reactive gas to decompose fluorine atoms in the glow discharge, and the silicon atoms on the surface of the silicon substrate 5 The reaction generates gaseous products to complete the etching of the vertical through hole 6; the reaction gas pressure is 24Pa, the reaction gas flow rate is 20 ml / min, and the radio frequency power range is 300W; during the etching process, heat exchangers and helium cooling technology are used Control the temperature of the silicon substrate to ensure that the temperature of the entire silicon substrate 5 during the etching process is uniform and stable at about 145°C;

[0052] Step 2, on the inner wall of the through hole 6, the annular dielectric layer 2 is prepared by the atmospheric pressure chemical vapor deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com