Method for processing thermoelectric separation substrate for LED

A processing method and technology of thermoelectric separation, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of thermoelectric separation substrates failing to dissipate heat, difficult to control the amount of glue overflowing, affecting heat conduction, etc., to achieve tight integration and improved production efficiency. , the effect of good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

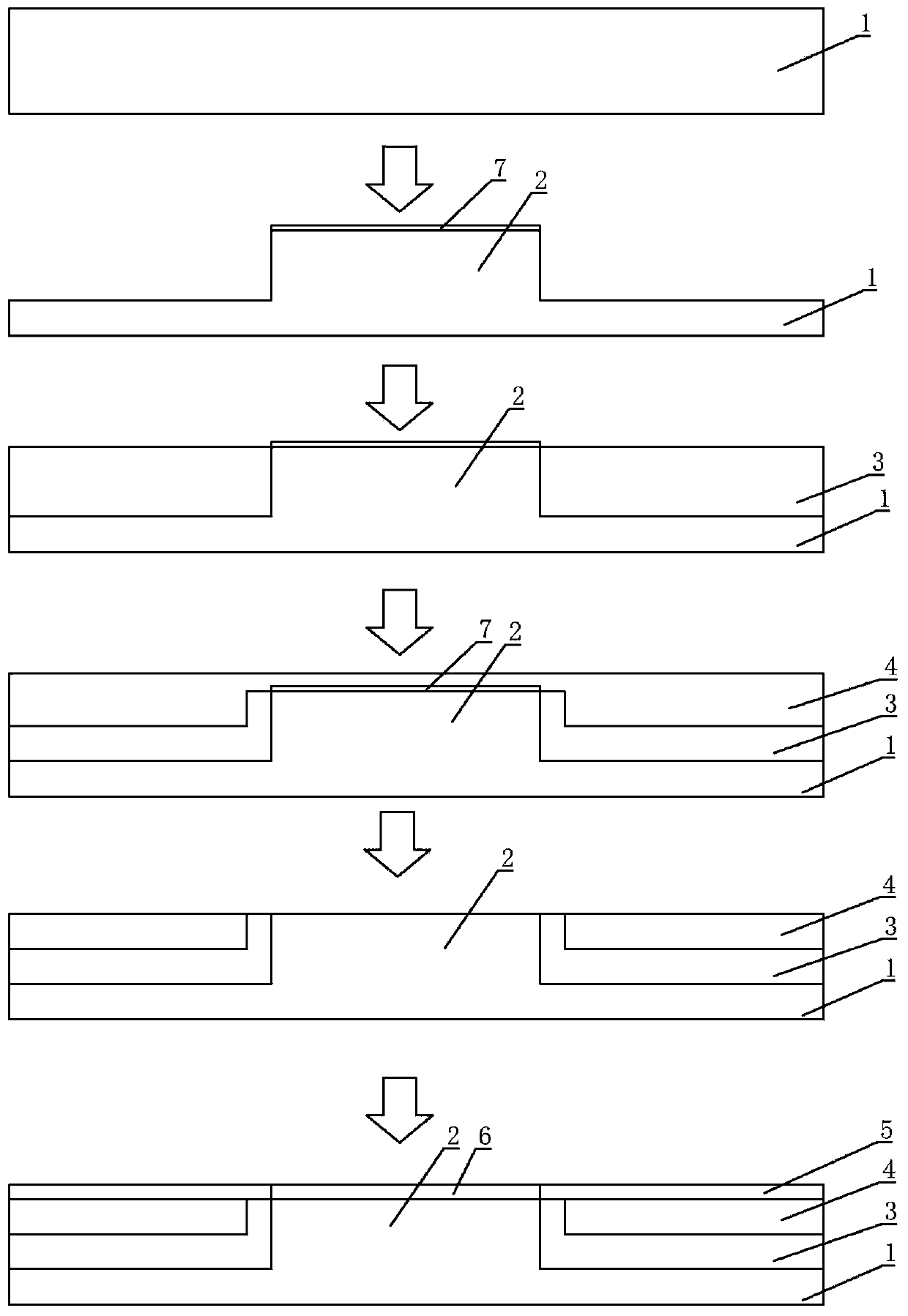

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

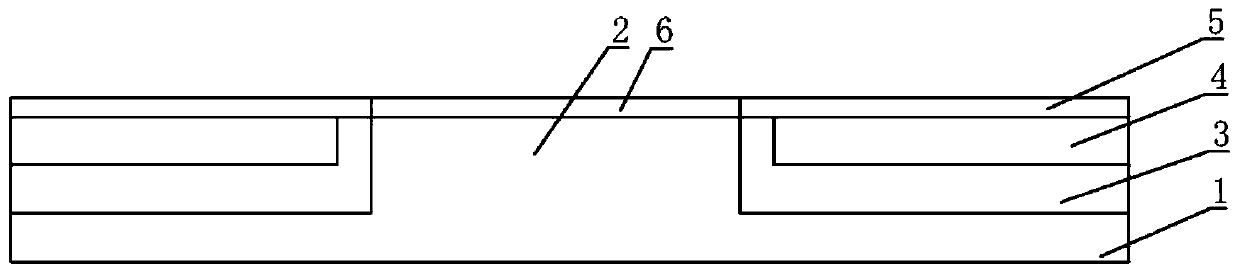

[0021] See figure 1 The thermoelectric separation substrate produced by the processing method of the thermoelectric separation substrate for LED of the present invention includes a copper substrate 1, a boss 2 on the copper substrate, a PP sheet 3 on both sides of the boss 2, and copper on the PP sheet 3. Foil 4, copper foil 4 is coated with ink 5 for solder resist, boss 2 is subjected to OSP surface treatment, and a layer of organic solder protection film 6 is grown chemically on the clean bare copper surface of boss 2 .

[0022] The above-mentioned processing method for a thermoelectric separation substrate for LEDs comprises the following steps: cutting the copper substrate, drilling an alignment tool hole on the copper substrate, then covering the copper substrate with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com