a tio 2 Base electrothermal coating and preparation method thereof

A coating and electric heating technology, applied in the coating, electric heating device, ohmic resistance heating and other directions, can solve the problems of uneven heating and short life, and achieve the effect of restoring the heating effect, low cost and improving the uniformity of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

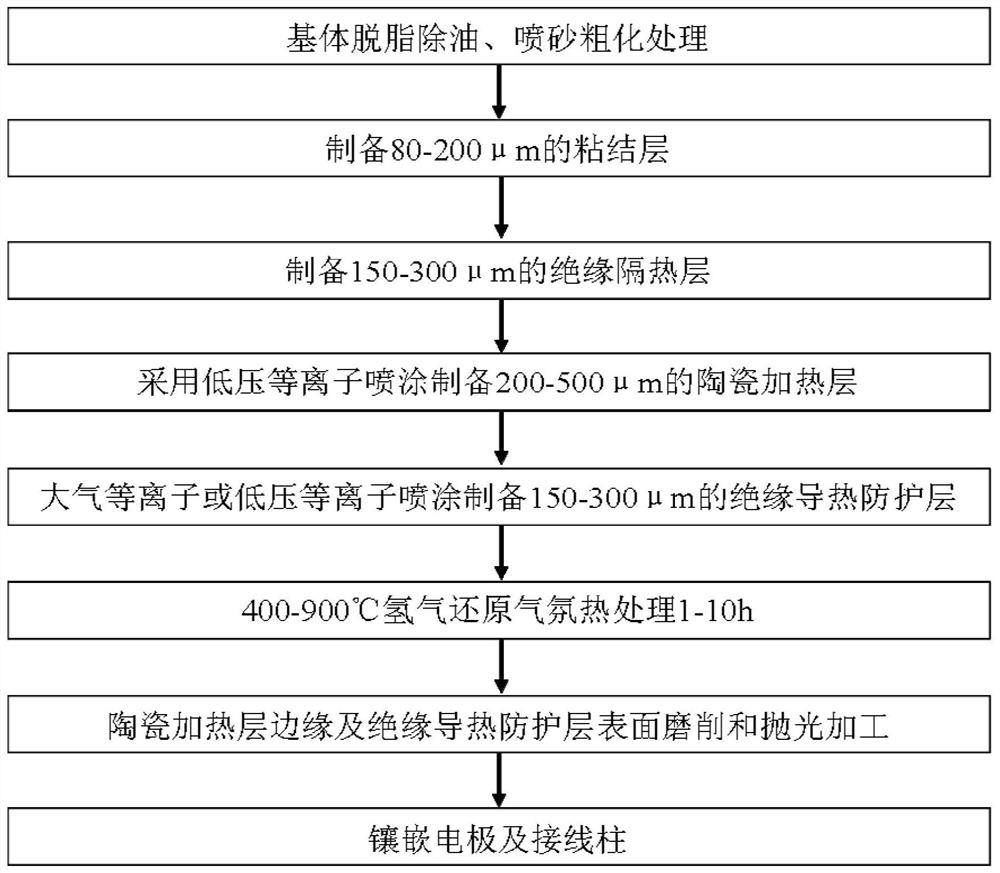

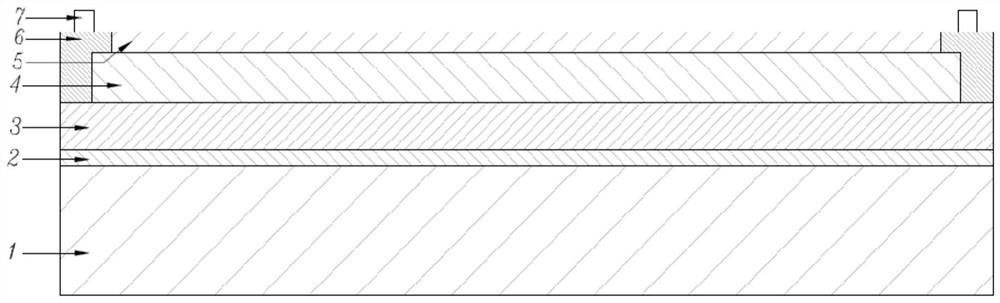

[0043] a TiO 2 Base electrothermal coating, its preparation method is as figure 1 shown, including the following steps:

[0044] (1) Degrease and degreasing the substrate, roughen the surface by sandblasting until the surface roughness Ra>3μm and preheat treatment, spray NiCr bonding layer with a thickness of 100μm and MgAl with a thickness of 200μm in turn 2 O 4 insulating layer;

[0045] (2) in MgAl 2 O 4 A ceramic heating layer is prepared on the surface of the insulating and heat insulating layer. The material of the ceramic heating layer is TiO 2 -40wt%MgAl 2 O 4 . Among them, TiO 2 Grain size 15-45μm, MgAl 2 O 4 The particle size is 10-45 μm. The spraying chamber is evacuated to below 100Pa, and then filled with a protective atmosphere to make the pressure in the spraying chamber 6kPa, the current of the plasma spray gun is 600A, the argon gas is 45L / min, the hydrogen gas is 12L / min, the spray distance is 270mm, and the gun speed is 400mm / s to obtain a cer...

Embodiment 2

[0051] a TiO 2 Base electrothermal coating, its preparation method comprises the steps:

[0052] (1) Degrease and degreasing the substrate, roughen the substrate by sandblasting until the surface roughness Ra>3μm and preheat treatment, spray NiAl bonding layer with a thickness of 120μm and Al with a thickness of 250μm in turn 2 O 3 insulating layer;

[0053] (2) in Al 2 O 3 A ceramic heating layer is prepared on the surface of the insulating and heat insulating layer. The material of the ceramic heating layer is TiO 2 -30wt% Al 2 O 3 . Among them, TiO 2 The particle size is 15-45μm, Al 2 O 3The particle size is 5-22 μm. The spraying chamber is evacuated to below 100Pa, and then filled with a protective atmosphere to make the pressure in the spraying chamber 13kPa, the current of the plasma spray gun is 620A, the argon gas is 42L / min, the hydrogen gas is 10L / min, the spray distance is 240mm, and the gun speed is 300mm / s to obtain a ceramic heating layer with a thi...

Embodiment 3

[0058] a TiO 2 Base electrothermal coating, its preparation method comprises the steps:

[0059] (1) Degrease and degreasing the substrate, roughen the substrate by sandblasting until the surface roughness Ra>3μm and preheat treatment, spray NiCrAlY adhesive layer with thickness of 90μm and YSZ insulation layer with thickness of 180μm in turn;

[0060] (2) A ceramic heating layer is prepared on the surface of the YSZ insulating layer. The material of the ceramic heating layer is TiO 2 -45wt% YSZ. Among them, TiO 2 The particle size is 10-45 μm, and the YSZ particle size is 22-45 μm. The spraying chamber is evacuated to below 100Pa, and then filled with a protective atmosphere to make the pressure in the spraying chamber 30kPa, the current of the plasma spray gun is 650A, the argon gas is 42L / min, the hydrogen gas is 9L / min, the spray distance is 180mm, and the gun speed is 500mm. / s to obtain a ceramic heating layer with a thickness of 260 μm;

[0061] (3) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com