Processing system for improving feed uniformity and use safety

A processing system and uniformity technology, applied in the molding or processing of animal feed, feed, animal feed, etc., can solve the problems of decreased product uniformity, high equipment input cost, low product quality, etc., and achieve uniformity and stability. Good results, low input and operating costs, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

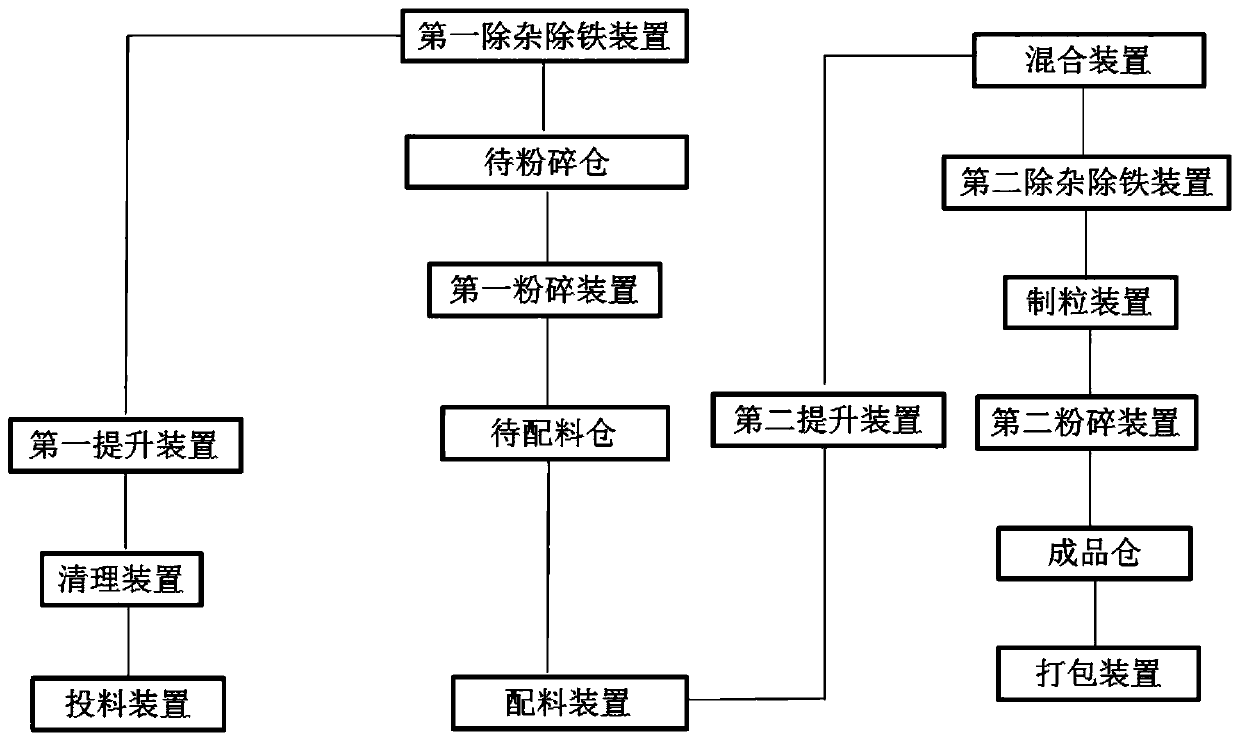

[0057] Such as figure 1 A processing system for improving feed uniformity and use safety, the processing system includes a feeding device, a cleaning device, a first lifting device, a first impurity and iron removal device, a bin to be crushed, a first crushing device, and a bin to be fed , batching device, second lifting device, mixing device, second impurity and iron removal device, granulation device, second crushing device, finished product warehouse, packing device;

[0058] Wherein the feeding device, the cleaning device, the first lifting device, and the first impurity and iron removal device are connected in sequence;

[0059] The batching device, the second lifting device, the mixing device, the second impurity and iron removal device, the granulation device, the second crushing device, the finished product bin, and the packaging device are connected in sequence;

[0060] The bin to be crushed, the first crushing device, the bin to be batched, and the batching device...

Embodiment 2

[0063] A processing system for improving feed uniformity and use safety. The processing system includes a feeding device, a cleaning device, a first lifting device, a first impurity and iron removal device, a bin to be crushed, a first crushing device, a bin to be fed, Dosing device, second lifting device, mixing device, second impurity and iron removal device, granulation device, second crushing device, finished product bin, packaging device; the mixing device is provided with a spray device;

[0064] Wherein the feeding device, the cleaning device, the first lifting device, and the first impurity and iron removal device are connected in sequence;

[0065] The batching device, the second lifting device, the mixing device, the second impurity and iron removal device, the granulation device, the second crushing device, the finished product bin, and the packaging device are connected in sequence;

[0066] The bin to be crushed, the first crushing device, the bin to be batched, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com