Foamed sodium alginate hydrogel, preparation method thereof, and fire extinguishing device

A sodium alginate and hydrogel technology, applied in fire protection equipment and other directions, can solve the problems of high density, easy foam rupture, rupture and failure, etc., and achieve the effect of wide application range, improved fire extinguishing effect, and strong universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

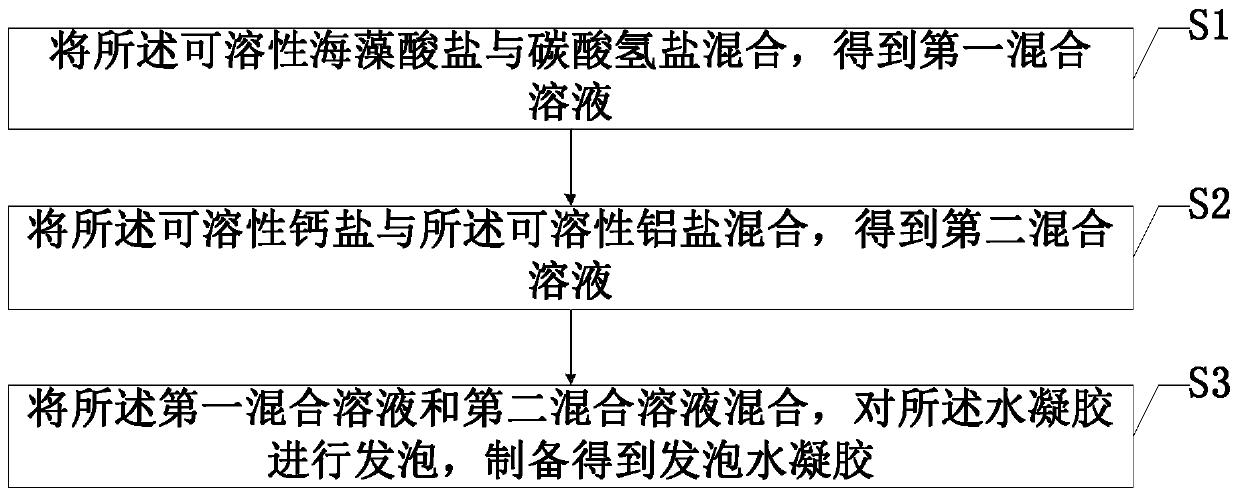

[0041] The second embodiment of the present invention also provides a method for preparing foamed sodium alginate hydrogel, the hydrogel comprising soluble alginate, soluble calcium salt and water, figure 2 It is a schematic diagram of the steps of the preparation method of the foamed sodium alginate hydrogel of the embodiment of the present invention, as figure 2 Shown, this preparation method comprises the following steps:

[0042] S1. Mix the soluble alginate and bicarbonate to obtain a first mixed solution.

[0043] S2. Mixing the soluble calcium salt and the soluble aluminum salt to obtain a second mixed solution;

[0044] S3. Mix the first mixed solution and the second mixed solution, and foam the hydrogel to prepare foamed sodium alginate hydrogel.

[0045] In step S1, in the first mixed solution, the mass fraction of the soluble alginate in water is 0.2-1 wt%, and the mass fraction of the bicarbonate in water is 4-6 wt%;

[0046] In step S2, in the second mixed so...

Embodiment 1

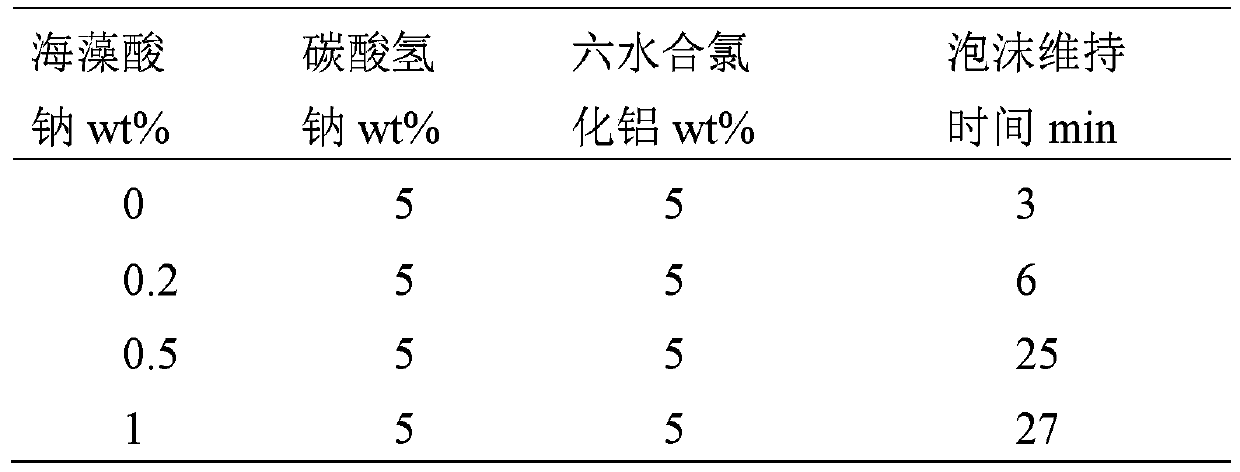

[0050] A foaming sodium alginate hydrogel prepared from the following raw material components: A. sodium alginate, B. sodium bicarbonate, C. calcium chloride, D. aluminum chloride hexahydrate, E. water, Concrete preparation, use method comprise the following steps:

[0051] (1) 2g sodium alginate, 40g sodium bicarbonate are evenly mixed and dissolved in 1000g deionized water to obtain mixed solution I;

[0052] (2) 10g of calcium chloride and 30g of aluminum chloride hexahydrate were mixed and dissolved in 1000g of deionized water to obtain mixed solution II;

[0053] (3) First spray the mixed solution I onto the surface of the combustion object, and then spray the mixed solution II onto the surface of the combustion object, the sodium alginate and calcium and aluminum ions are instantly cross-linked, and the sodium bicarbonate and aluminum ions are instantly foamed to form a hydrogel The foam layer covers the surface of the burning object and extinguishes the fire source.

Embodiment 2

[0055] A foaming sodium alginate hydrogel fire extinguishing agent, prepared from the following raw material components: A. Sodium alginate, B. Potassium bicarbonate, C. Calcium bromide, D. Aluminum sulfate, E. Water, specifically The preparation and use methods comprise the following steps:

[0056] (1) 6g sodium alginate, 45g potassium bicarbonate are evenly mixed and dissolved in 1000g deionized water to obtain mixed solution I;

[0057] (2) Dissolve in 1000g deionized water after mixing 20g calcium bromide and 45g aluminum sulfate to obtain mixed solution II;

[0058] (3) Spray mixed solution I and mixed solution II onto the surface of the combustion object at the same time, sodium alginate and calcium and aluminum ions are instantly cross-linked, potassium bicarbonate and aluminum ions are instantly foamed to form a hydrogel foam layer covering the surface of the combustion object , Extinguish the fire source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com