Preparation method and application of biomass carbon tube assisted MoS2 hydrogen evolution catalyst

A biomass carbon and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of limited natural resources and high cost, and achieve good conductivity, low cost, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation method of biomass carbon tube assisted MoS2 hydrogen evolution catalyst

[0026] In this implementation, proceed in the following order of steps:

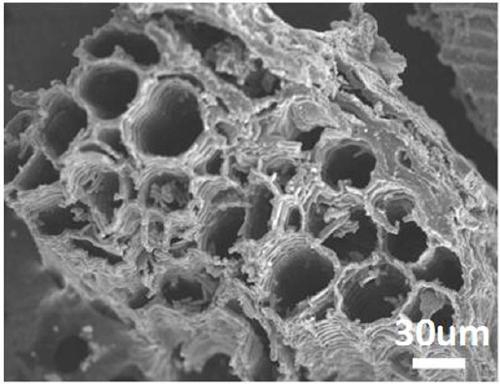

[0027] (1) Carbonization of biomass

[0028] Soak the washed celery sticks in 5wt% acid for 2.5 hours to remove K + and other impurities; then utilize ultra-pure water to rinse the celery stalks after acid soaking treatment 7 times, remove the acid attached to the celery stalks, put the celery stalks into a freeze dryer and dry until the water content is 7 wt%. . The dried celery was placed in a tube furnace, and under the protection of nitrogen, the celery stalks were heated from room temperature to 760 ˚C at a heating rate of 5 ˚C / min and kept for 2.8 hours to prepare biomass carbon tubes Matrix A;

[0029] (2) Biomass carbon tube assisted MoS 2 preparation of

[0030] Dissolve the powder of ammonium molybdate: thiourea: biomass carbon tube substrate A in water according to the mass ratio of 1:2...

Embodiment 2~8

[0031] Examples 2-8 Biomass carbon tube assisted MoS 2 Preparation method of hydrogen evolution catalyst

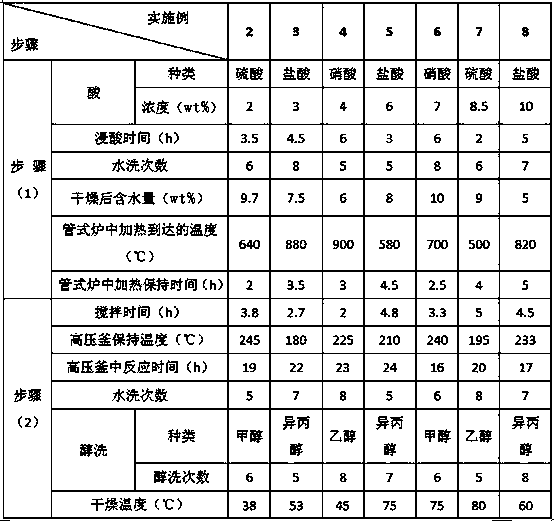

[0032] Examples 2-8 are respectively a kind of biomass carbon tube assisted MoS 2 The preparation method of the hydrogen evolution catalyst, the preparation method is the same as the preparation method of Example 1, the difference is that the reaction conditions involved in each step, the substances used and the amount are different, specifically see Table 1

[0033] Table 1

[0034]

Embodiment 9

[0035] Example 9 Biomass carbon tube assisted MoS 2 Application of hydrogen evolution catalyst

[0036] This embodiment provides a kind of biomass carbon tube assisted MoS using any one of embodiments 1-8. 2 Biomass carbon tube assisted MoS prepared by the preparation method of hydrogen evolution catalyst 2 The application of the hydrogen evolution catalyst, which is used as a catalyst in the industrial electrocatalytic hydrogen evolution reaction to prepare hydrogen.

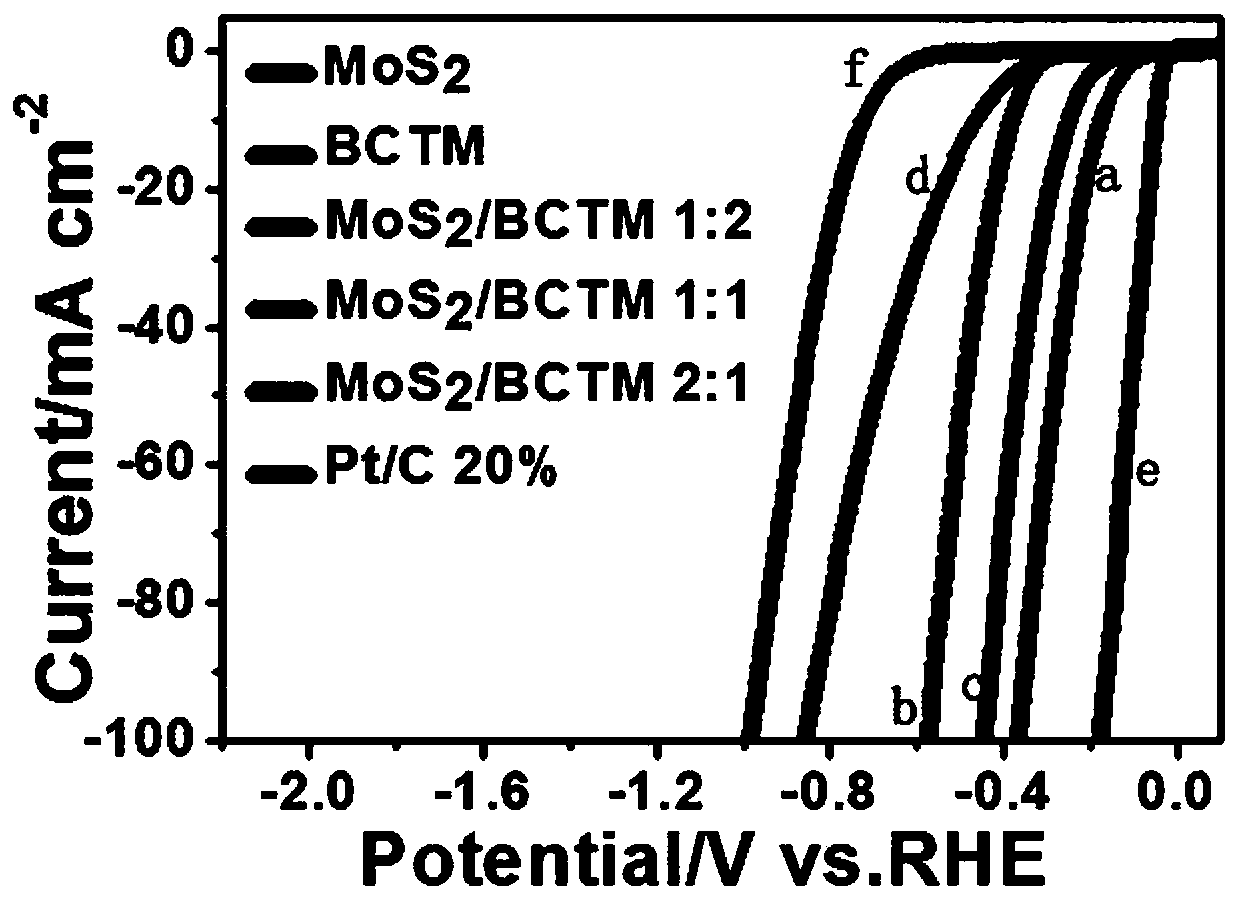

[0037] The biomass carbon tube assisted MoS obtained in embodiment 1~8 2 MoS in hydrogen evolution catalyst 2 : The mass ratio of the biomass carbonization tube matrix A is 1:1. When it is applied to the electrocatalytic hydrogen evolution reaction, the linear scanning curve of the performance is as follows figure 2 As shown in the curve a of , at the same time, according to the preparation method of Examples 1-8, MoS was obtained by changing the powder amounts of ammonium molybdate, thiourea and biomass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com