A process for producing machine-made sand and coal powder from coal gangue

A process method and coal gangue technology, which is applied in the field of producing machine-made sand and coal powder by using coal gangue, can solve the problems of low calorific value, many environmental protection problems, and small scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

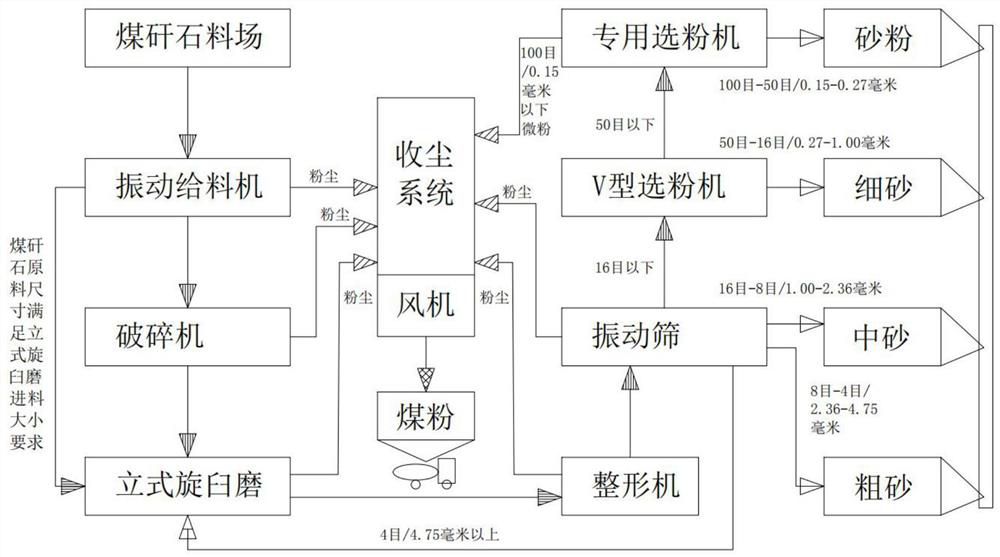

Image

Examples

Embodiment 1

[0031] Step 1: Crushing, the vibrating feeder sends the large pieces of coal gangue from the coal gangue stockyard to the crusher for crushing. After crushing, the particle size is 20~100mm; after crushing, it is sent to the vertical rotary mortar mill;

[0032] Step 2: Grinding. The vertical rotary mortar mill will squeeze the material into the material layer to dissociate the soft and hard substances of the coal gangue and grind the material to the designed particle size range, and then the material is transported to the vibrating screen;

[0033] Step 3: Screening. The vibrating screen is provided with three layers of sieve plates with different apertures, which are respectively the largest aperture sieve plate with an aperture size of 4 mesh, the medium aperture sieve plate with an aperture size of 8 mesh, and the small aperture sieve plate with an aperture size of 16 mesh; The product on the sieve plate with aperture is returned to the rotary mill for re-grinding, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com