Sub-nanoscale mandrel for manufacturing grazing-incidence reflection lens by replication and manufacturing process

A sub-nano-scale, manufacturing process technology, applied in the field of ultra-smooth sub-nano-scale mandrel manufacturing process, can solve the problems of large-area collection of X-rays, difficult surface roughness of nickel-phosphorus alloys, low X-ray reflection efficiency, etc. , to achieve the effect of ensuring surface quality, reducing processing costs and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

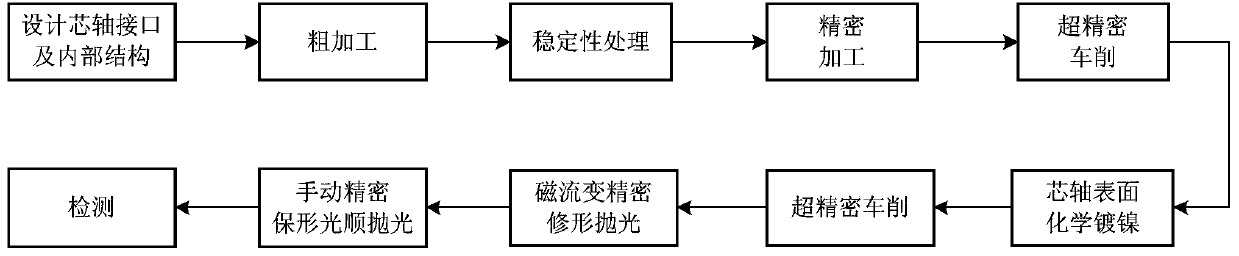

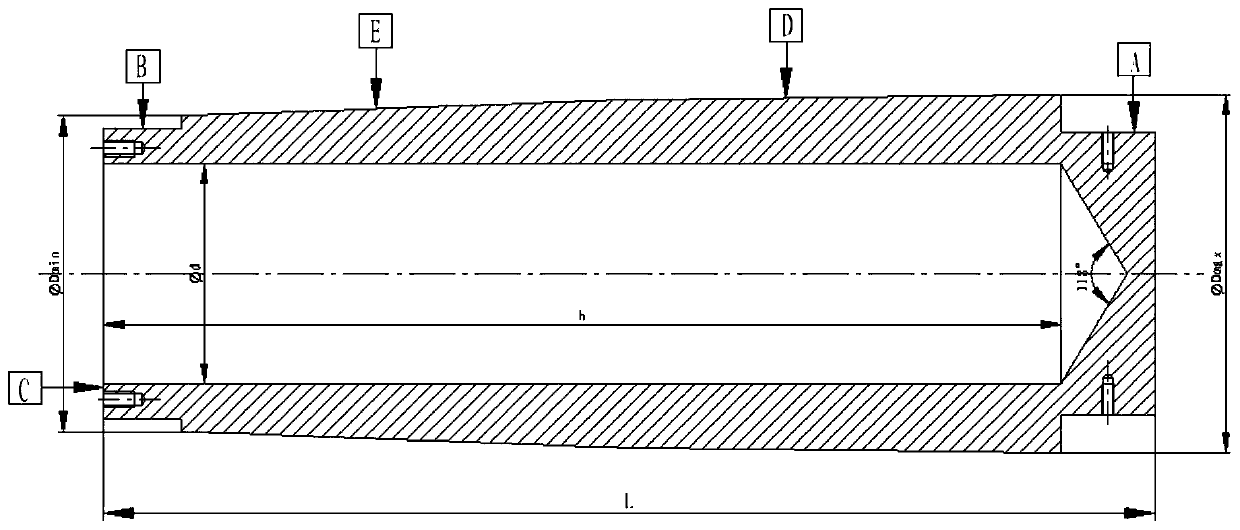

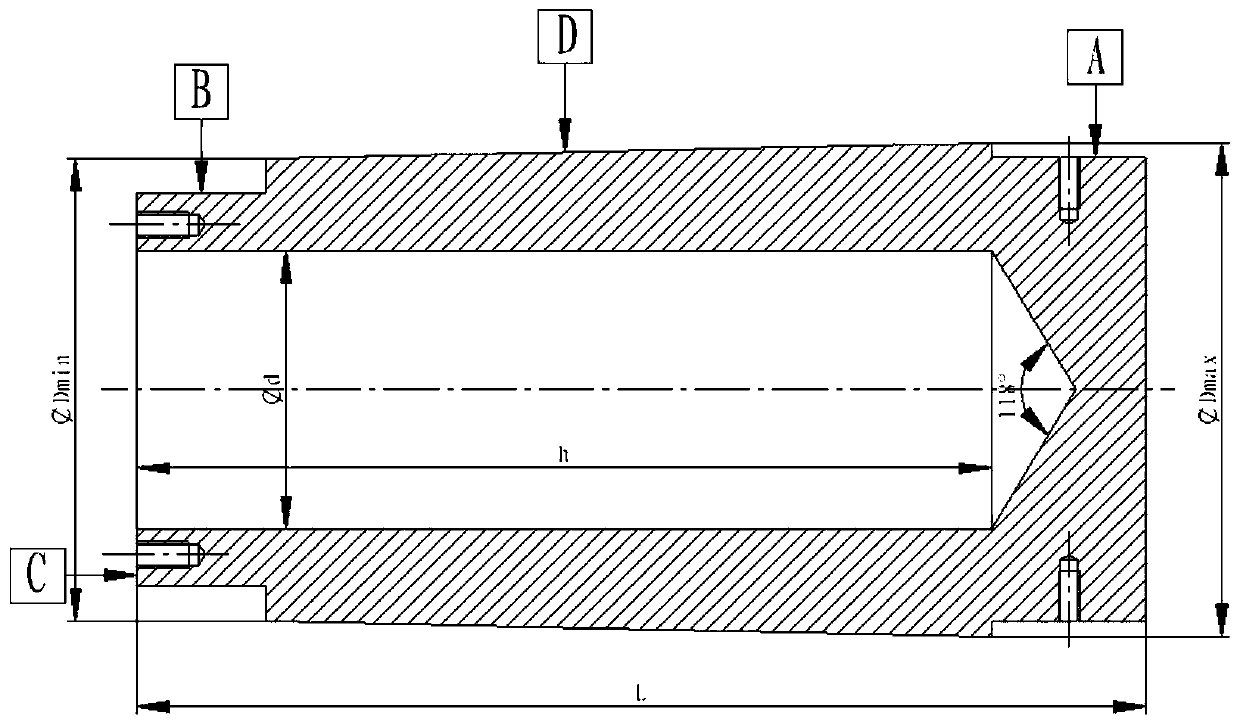

[0072] Using this manufacturing process to process a certain size of double reflection grazing incidence precision mandrel, as attached Figure 2b ) As shown in the figure, the maximum diameter of the mandrel is D max =114mm, minimum diameter D min =100.524mm, total length of mandrel L=330mm, diameter of blind hole d=65mm, depth of blind hole h=300mm. After mandrel rough machining, stability treatment, precision machining, ultra-precision turning, then electroless nickel plating with a thickness of 80-90μm, ultra-precision turning to a surface roughness of 9nm, and then magnetorheological modification and polishing, the surface roughness can reach 0.75-0.9nm, and finally manual conformal smooth polishing.

[0073] Implementation effect: After processing, the precision of the grazing incidence mandrel can reach 1 μm, and the surface roughness of the white light interferometer can reach RMS 0.4nm. At the same time, the mandrel has been used as a mold to replicate and process u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com