Method for continuously peeling graphite oxide in flowing mode and classifying graphene based on size

A technology of oxidized rock and graphene, applied in chemical instruments and methods, nanotechnology for materials and surface science, carbon compounds, etc., can solve the problems of unobvious size grading, uncontrollable size, and inapplicability, and achieve improvement Quality and size uniformity, improved performance, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Graphene oxide preparation:

[0042] Disperse graphite oxide in water to make a concentration of 2g / L. The amount of dispersant added is 1% of the mass of the graphite dispersion. Take 10L of the solution, mix it with 100 polyethylene balls and pour it into the reaction pool. The diameter of the ball is 1cm, density 1.1g / cm 3 . Turn on the ultrasonic device and the stirring device, the ultrasonic frequency is 40 kHz, and the stirring speed is 1000 r / min.

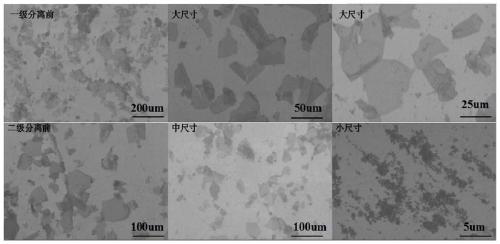

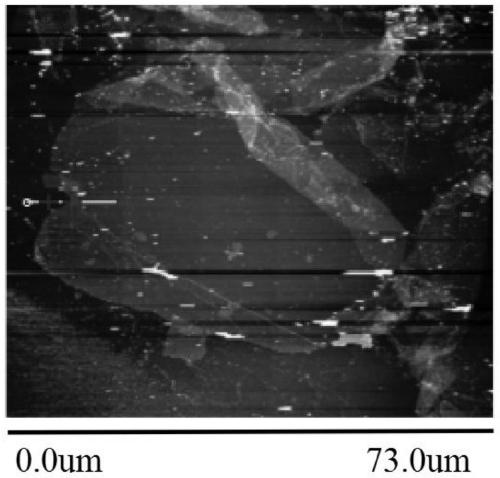

[0043] 2) Graphene oxide size fractionation preparation:

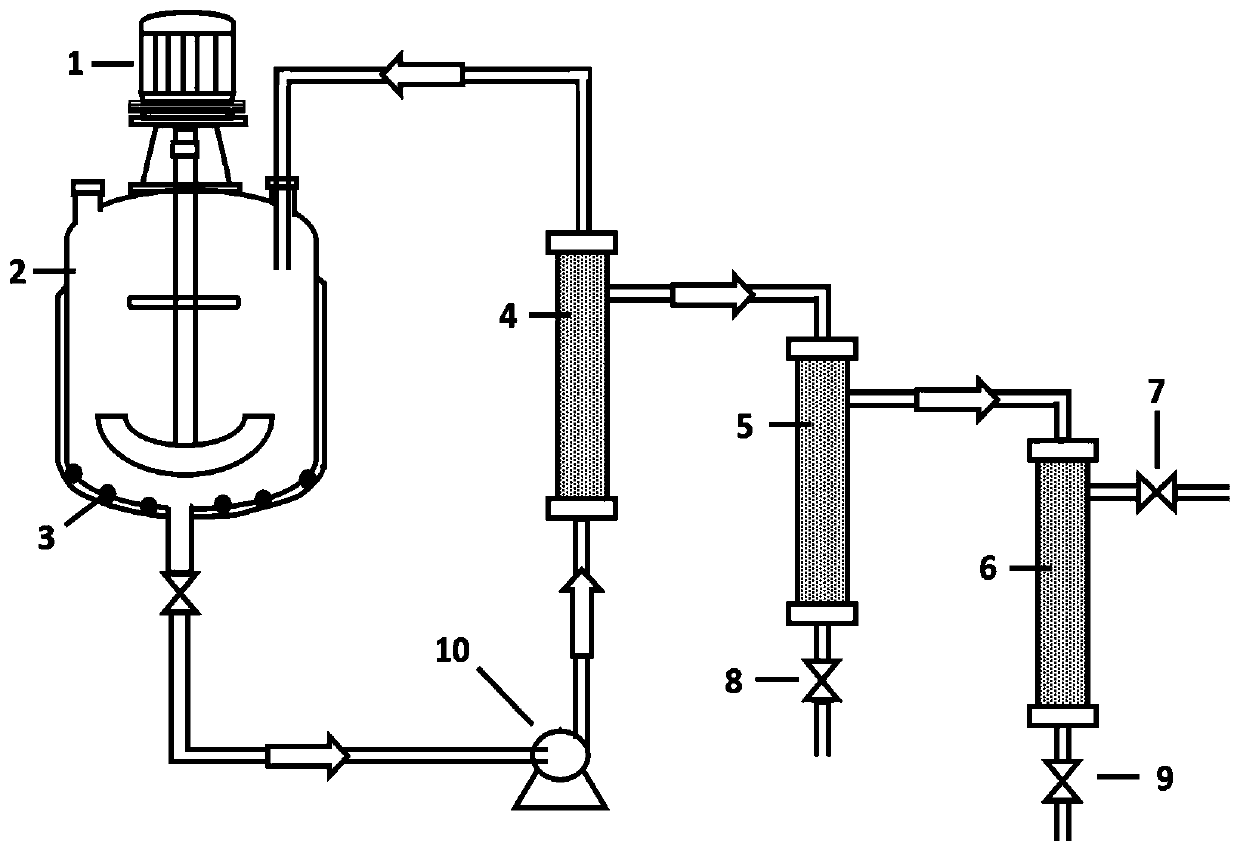

[0044] In the membrane separation device, the pore diameter of the primary separation membrane tube is 50um, the pore diameter of the secondary separation membrane tube is 5um, and the pore diameter of the tertiary membrane tube is 0.5um. Open the valve connected to the membrane separation device, turn on the centrifugal pump, and collect three graphene oxides with different size distributions in beakers.

[0045] figure 1 Process flow chart for the pr...

Embodiment 2

[0047] 1) Graphene oxide preparation:

[0048] Disperse graphite oxide in water to make a concentration of 4g / L. The amount of dispersant added is 2% of the mass of the graphite dispersion. Take 15L of the solution, mix it with 120 polypropylene pellets and pour it into the reaction pool. The diameter of the pellet is 2cm, density 1.2g / cm 3 . Turn on the ultrasonic device and the stirring device, the ultrasonic frequency is 100 kHz, and the stirring speed is 3000 r / min.

[0049] 2) Graphene oxide size fractionation preparation:

[0050] In the membrane separation device, the pore diameter of the primary separation membrane tube is 100um, the pore diameter of the secondary separation membrane tube is 50um, and the pore diameter of the third stage membrane tube is 1um. Open the valve connected to the membrane separation device, turn on the centrifugal pump, and collect three graphene oxides with different size distributions in beakers.

Embodiment 3

[0052] 1) Graphene oxide preparation:

[0053] Disperse graphite oxide in water to a concentration of 1g / L. The amount of dispersant added is 0.5% of the mass of the graphite dispersion. Take 7L of the solution, mix it with 60 polyamide balls and pour it into the reaction pool. The diameter of the ball is 1.5cm, density 1.0g / cm 3 . Turn on the ultrasonic device and the stirring device, the ultrasonic frequency is 60 kHz, and the stirring speed is 2000 r / min.

[0054] 2) Graphene oxide size fractionation preparation:

[0055] In the membrane separation device, the pore diameter of the primary separation membrane tube is 70um, the pore diameter of the secondary separation membrane tube is 2um, and the pore diameter of the tertiary membrane tube is 0.2um. Open the valve connected to the membrane separation device, turn on the centrifugal pump, and collect three graphene oxides with different size distributions in beakers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com