Metal and ceramic compounded material

A technology of ceramic composite materials and ceramic materials, which is applied in the direction of additive processing, etc., can solve the problems of poor repeatability of the spatial structure of composite materials, inability to precisely control the distribution of preforms, and complicated preparation methods, and achieve high repeatability and molding. The effect of good effect and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

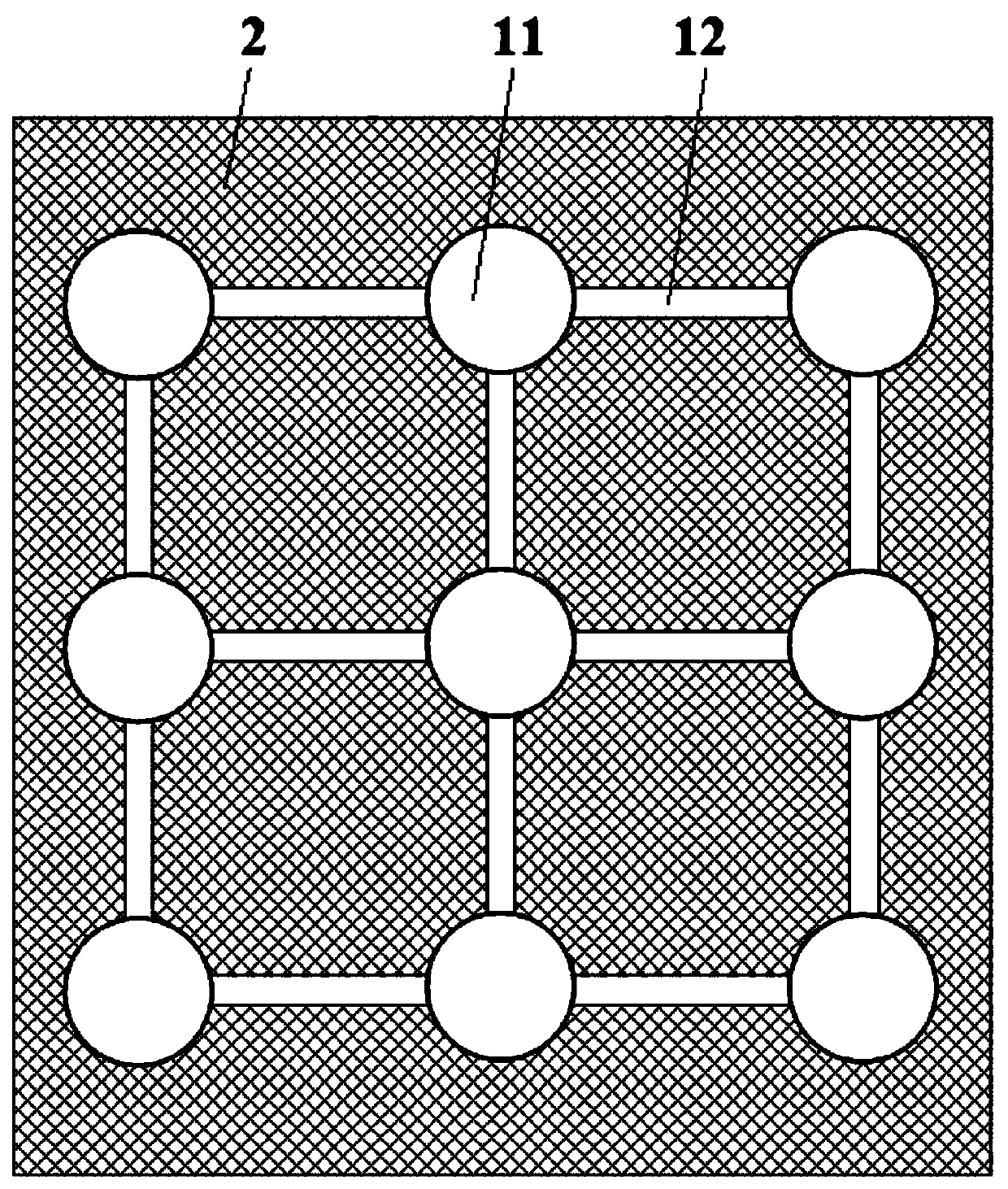

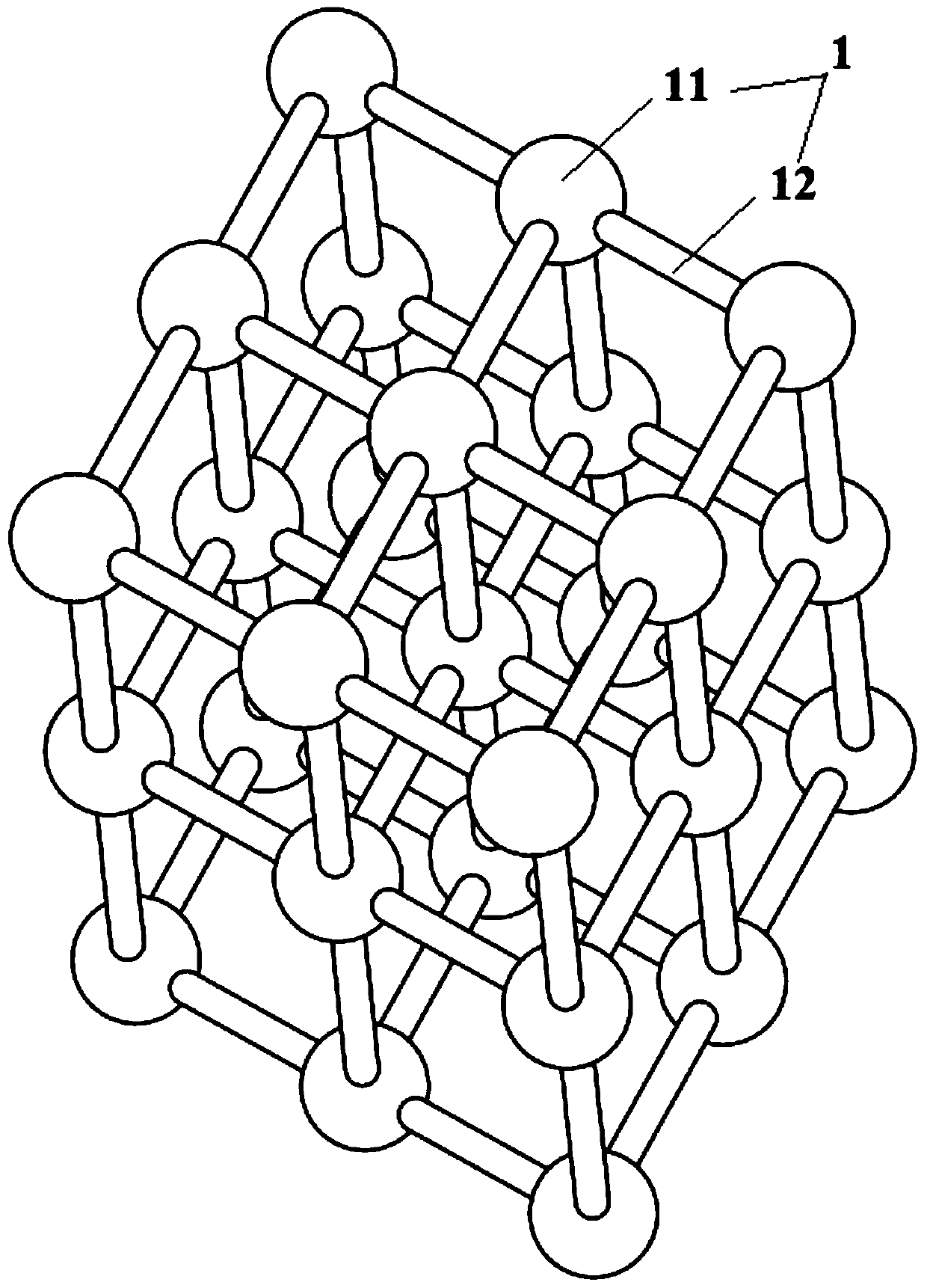

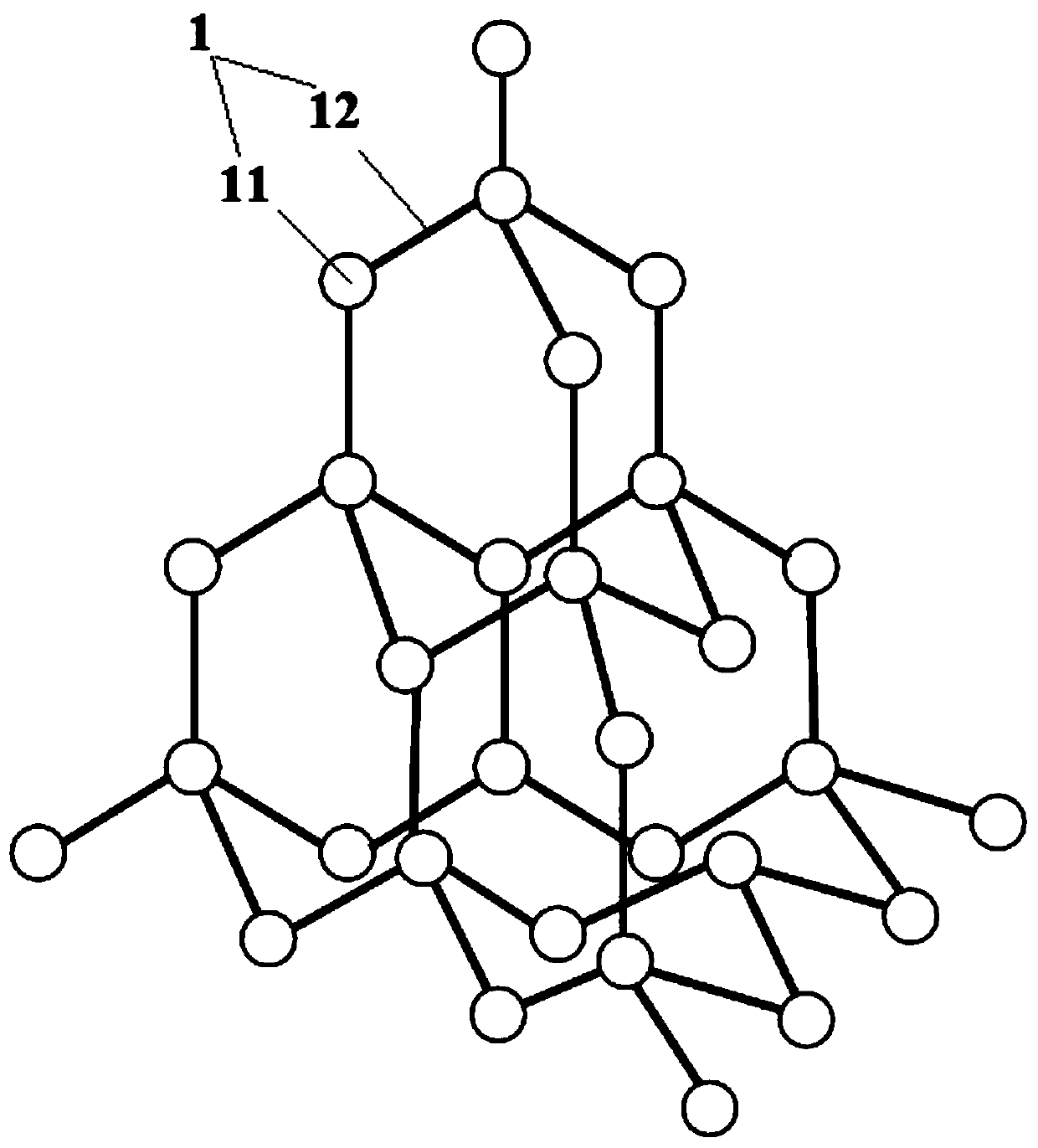

[0029] see Figure 1-3 , the present invention provides a technical solution, a metal and ceramic composite material, including a ceramic skeleton 1 and a metal matrix 2, the interior of the metal matrix 2 is provided with a ceramic skeleton 1, and the ceramic skeleton 1 is composed of several hollow ceramics A three-dimensional network structure composed of balls 11 and several ceramic rods 12 for connecting two adjacent hollow ceramic balls 11.

[0030] Wherein, in this embodiment, the ceramic skeleton 1 is made of ceramic material, wherein the ceramic material includes ceramic powder and binder, and the ceramic powder includes oxide ceramic particles, carbide ceramic particles or nitride ceramic particles. One or more mixtures, the average particle size range is 0.1-3mm.

[0031] Wherein, in this embodiment, the oxide ceramic particles are one or more of white corundum particles, brown corundum particles or ZrO2-Al2O3 particles.

[0032] Wherein, in this embodiment, the c...

Embodiment 2

[0047] see Figure 1-3 , the present invention provides a technical solution, a metal and ceramic composite material, including a ceramic skeleton 1 and a metal matrix 2, the interior of the metal matrix 2 is provided with a ceramic skeleton 1, and the ceramic skeleton 1 is composed of several hollow ceramics A three-dimensional network structure composed of balls 11 and several ceramic rods 12 for connecting two adjacent hollow ceramic balls 11.

[0048]Wherein, in this embodiment, the ceramic skeleton 1 is made of ceramic material, wherein the ceramic material includes ceramic powder and binder, and the ceramic powder includes oxide ceramic particles, carbide ceramic particles or nitride ceramic particles. One or more mixtures, the average particle size range is 0.1-3mm.

[0049] Wherein, in this embodiment, the oxide ceramic particles are one or more of white corundum particles, brown corundum particles or ZrO2-Al2O3 particles.

[0050] Wherein, in this embodiment, the ca...

Embodiment 3

[0065] see Figure 1-3 , the present invention provides a technical solution, a metal and ceramic composite material, including a ceramic skeleton 1 and a metal matrix 2, the interior of the metal matrix 2 is provided with a ceramic skeleton 1, and the ceramic skeleton 1 is composed of several hollow ceramics A three-dimensional network structure composed of balls 11 and several ceramic rods 12 for connecting two adjacent hollow ceramic balls 11.

[0066] Wherein, in this embodiment, the ceramic skeleton 1 is made of ceramic material, wherein the ceramic material includes ceramic powder and binder, and the ceramic powder includes oxide ceramic particles, carbide ceramic particles or nitride ceramic particles. One or more mixtures, the average particle size range is 0.1-3mm.

[0067] Wherein, in this embodiment, the oxide ceramic particles are one or more of white corundum particles, brown corundum particles or ZrO2-Al2O3 particles.

[0068] Wherein, in this embodiment, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com