Anti-blocking agent suitable for powder water-soluble fertilizer and preparation method of anti-blocking agent

An anti-caking agent, water-soluble technology, applied in the direction of organic fertilizers, fertilizer mixtures, fertilizers made of biological waste, etc., can solve problems such as high viscosity and high moisture absorption, achieve low production costs, simple production processes, and improve anti-caking The effect of block performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

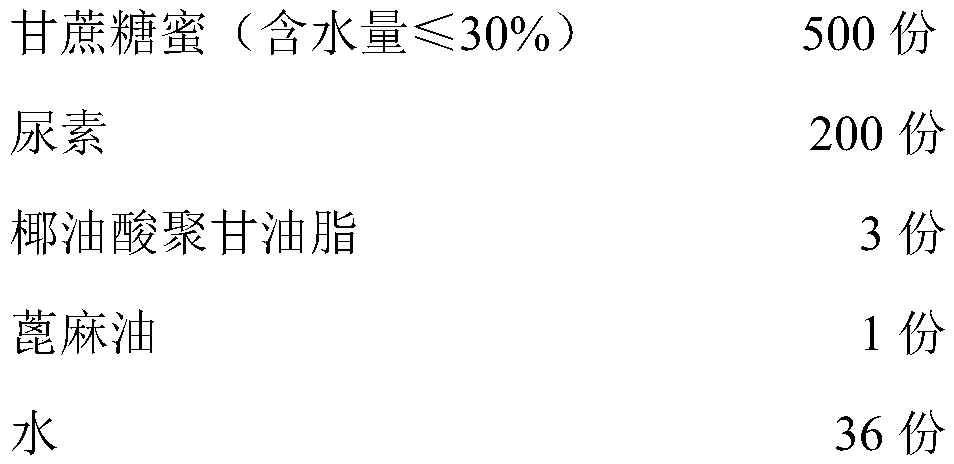

[0026] An anti-caking agent suitable for powder water-soluble fertilizers, comprising the following components in parts by weight:

[0027]

[0028] The preparation method of above-mentioned anti-caking agent for powder fertilizer comprises the following steps:

[0029] S1, adjusting the mixer of the heating and stirring device to a rotating speed of 1000 rpm, adding sugarcane molasses and urea, and stirring evenly to obtain viscosity-reducing sugarcane molasses;

[0030] S2, adding polyglycerol cocoate release agent and castor oil into water, heating and dissolving to prepare a mixed solution with a mass fraction of 10%;

[0031] S3. Add the mixed solution prepared in step S2 to the reduced-viscosity molasses prepared in step S1, turn on the heating switch of the heating and stirring device, and set the heating temperature to 80°C; adjust the speed of the mixer to 800 rpm, set Heating and stirring at low temperature for 30min;

[0032] S4. Filter the heated and stirred s...

Embodiment 2

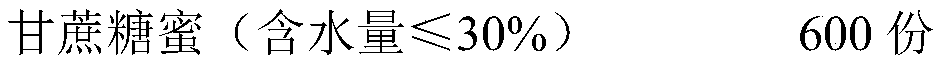

[0034] An anti-caking agent suitable for powder water-soluble fertilizers, comprising the following components in parts by weight:

[0035]

[0036]

[0037] The preparation method of the above-mentioned anti-caking agent suitable for powder water-soluble fertilizer comprises the following steps:

[0038] S1. The mixer of the heating and stirring device is adjusted to a rotating speed of 2000 rpm, adding sugarcane molasses, urea and ammonium chloride, and stirring evenly to obtain viscous molasses;

[0039] S2, adding sucrose fatty acid ester, sucrose polyether, olive oil and palm oil into water, heating and dissolving to prepare a mixed solution with a mass fraction of 10%;

[0040] S3. Add the mixed solution prepared in step S2 to the reduced-viscosity molasses prepared in step S1, turn on the heating switch of the heating and stirring device, and set the heating temperature to 100°C; adjust the speed of the mixer to 400 rpm, set Heating and stirring at high temperatu...

Embodiment 3

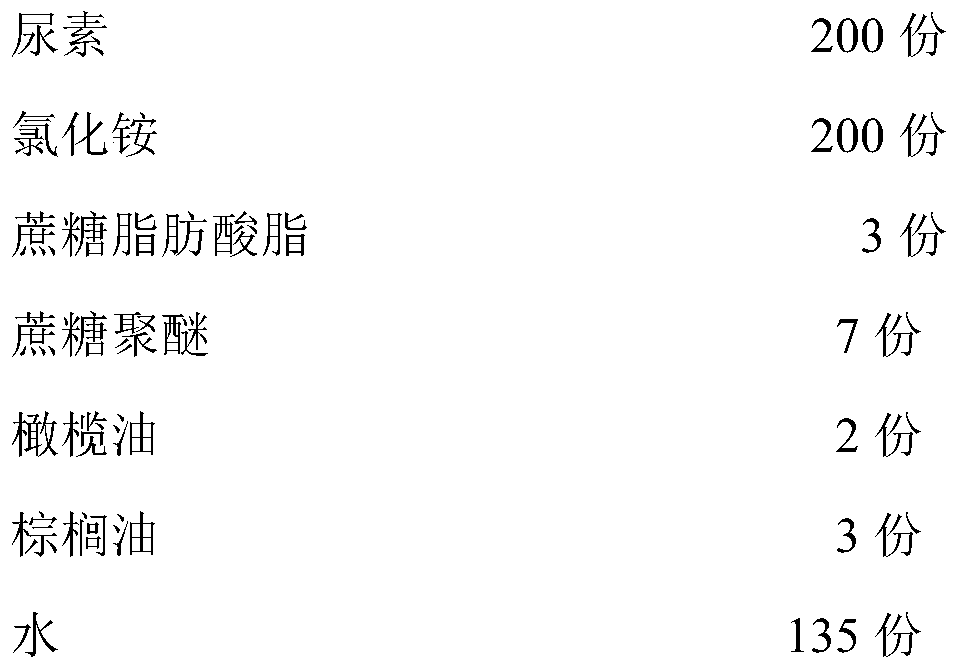

[0043] An anti-caking agent suitable for powder water-soluble fertilizers, comprising the following components in parts by weight:

[0044]

[0045] The preparation method of the above-mentioned anti-caking agent suitable for powder water-soluble fertilizer comprises the following steps:

[0046] S1. Adjust the mixer of the heating and stirring device to a rotating speed of 1250 rpm, add beet molasses and ammonium nitrate, and stir evenly to obtain viscosity-reducing molasses;

[0047] S2, adding sucrose polyether and palm oil into water, heating and dissolving to prepare a mixed solution with a mass fraction of 5%;

[0048] S3. Add the mixed solution prepared in step S2 to the reduced-viscosity molasses prepared in step S1, turn on the heating switch of the heating and stirring device, and set the heating temperature to 100°C; adjust the speed of the mixer to 800 rpm, set Heating and stirring at low temperature for 15 minutes;

[0049] S4. Filter the heated and stirred s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com