Water-soluble ammonium phosphate fertilizer wrapping agent and preparation method thereof

A water-soluble, wrapping agent technology, applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc., can solve environmental pollution and other problems, achieve good effect, good anti-caking, and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

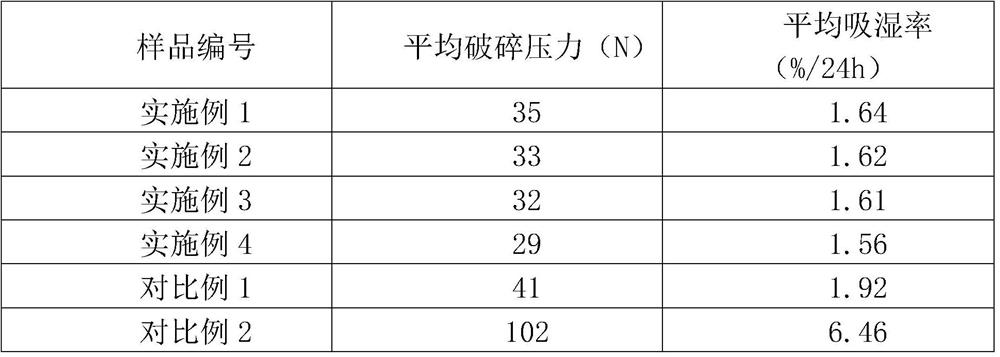

Examples

preparation example Construction

[0019] A water-soluble ammonium phosphate fertilizer coating agent and a preparation method thereof. The coating agent includes the following components in parts by weight: 10-20 parts of plasticized modified polyvinyl alcohol, 10-30 parts of cross-linked starch and 50-80 parts of water; The plasticized modified polyvinyl alcohol is obtained by heat fusion of plasticizer and polyvinyl alcohol, and the cross-linked starch is obtained by cross-linking reaction of cross-linking agent and starch under the action of a catalyst.

[0020] The plasticized modified polyvinyl alcohol and cross-linked starch in the technical solution are used as the main components of the wrapping agent to form a coating layer on the surface of the fertilizer. Polyvinyl alcohol (PVA) is a degradable, water-soluble and film-forming polyhydroxy polymer. However, since the melting point temperature (200-250°C) of PVA is very close to the decomposition temperature, melt blending is currently used to plastici...

Embodiment 1

[0023] This embodiment provides a water-soluble ammonium phosphate fertilizer coating agent, which includes the following components in parts by weight: 10% plasticized modified polyvinyl alcohol, 10% cross-linked starch and 80% water. The preparation method is as follows: add 70g of polyvinyl alcohol and 30g of glycerin-ethylene glycol (wherein the weight ratio of glycerol to ethylene glycol is 4:1) compound plasticizer to a high mixer, mix at a temperature of 80°C for 1 hour, After cooling and crushing, powdery plasticized modified polyvinyl alcohol is obtained; potato starch and water are prepared into 36% starch milk in a reaction kettle, and 0.1% phosphorus oxychloride is added to account for the mass of dry potato starch, and 0.1mol / L Adjust the pH of the sodium hydroxide solution to 10.5, react at 45°C for 1.5h, centrifuge, filter, wash with water, dry, pulverize, and sieve to obtain powdery cross-linked starch; weigh 10g of plasticized modified polysaccharide Dissolve ...

Embodiment 2

[0026] This embodiment provides a water-soluble ammonium phosphate fertilizer coating agent, which includes the following components in parts by weight: 10% plasticized modified polyvinyl alcohol, 30% cross-linked starch and 60% water. The preparation method is as follows: add 70g of polyvinyl alcohol and 30g of urea-triethanolamine (where the weight ratio of urea to triethanolamine is 1:1) compound plasticizer into a high mixer, mix at 80°C for 1 hour, cool and pulverize After that, powdery plasticized modified polyvinyl alcohol is obtained; cornstarch is prepared into 40% starch milk with water, 1% sodium trimetaphosphate accounting for the mass of dry cornstarch is added, and the pH is adjusted with 0.1mol / L sodium hydroxide solution to 10, react at 50°C for 1.5h, centrifuge, filter, wash with water, dry, pulverize, and sieve to obtain powdery cross-linked starch; weigh 10g of plasticized modified polyvinyl alcohol and 30g of modified starch In 60g of water, stir and mix ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com