Regeneration method and system for emulsion containing heavy metal ions

A technology of heavy metal ion and regeneration system, applied in the field of waste emulsion treatment, can solve the problems of decreased stability and uniformity of emulsion, destruction of emulsion oil-water two-phase uniformity, and waste of lubricant environment, etc. The effect of improving utilization and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0032] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

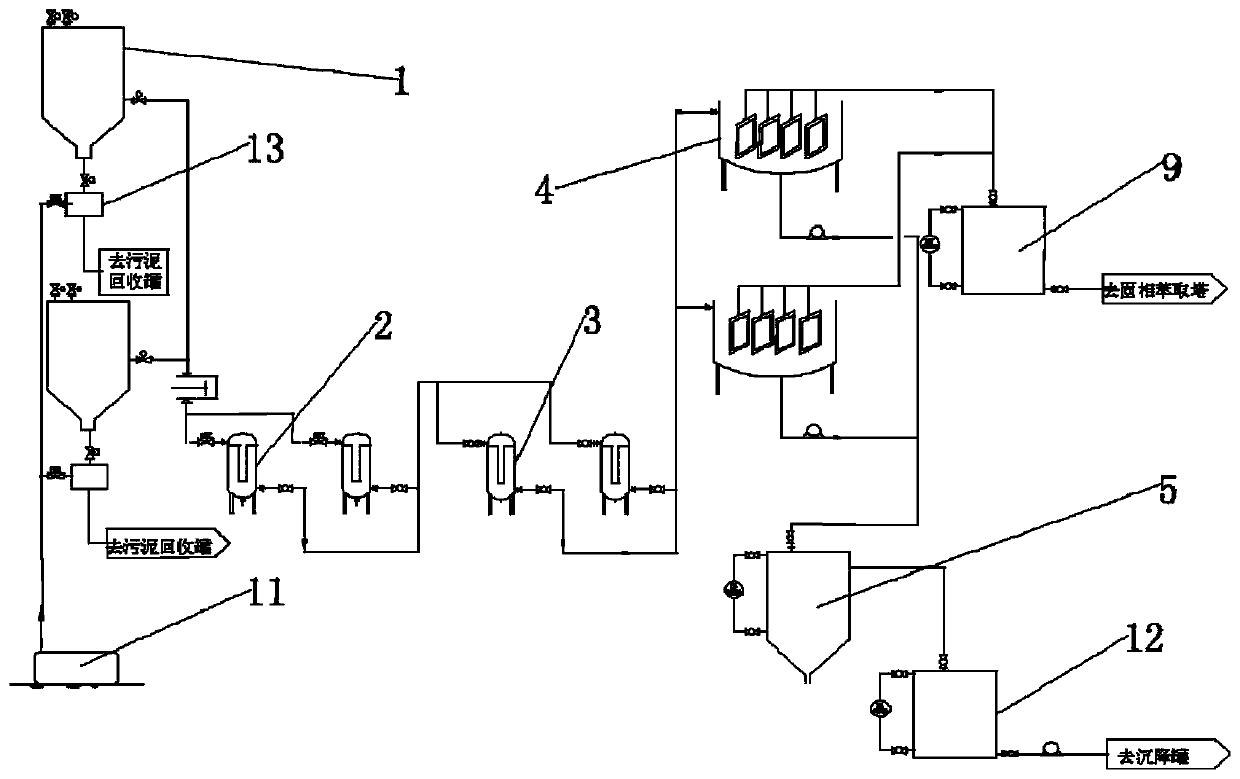

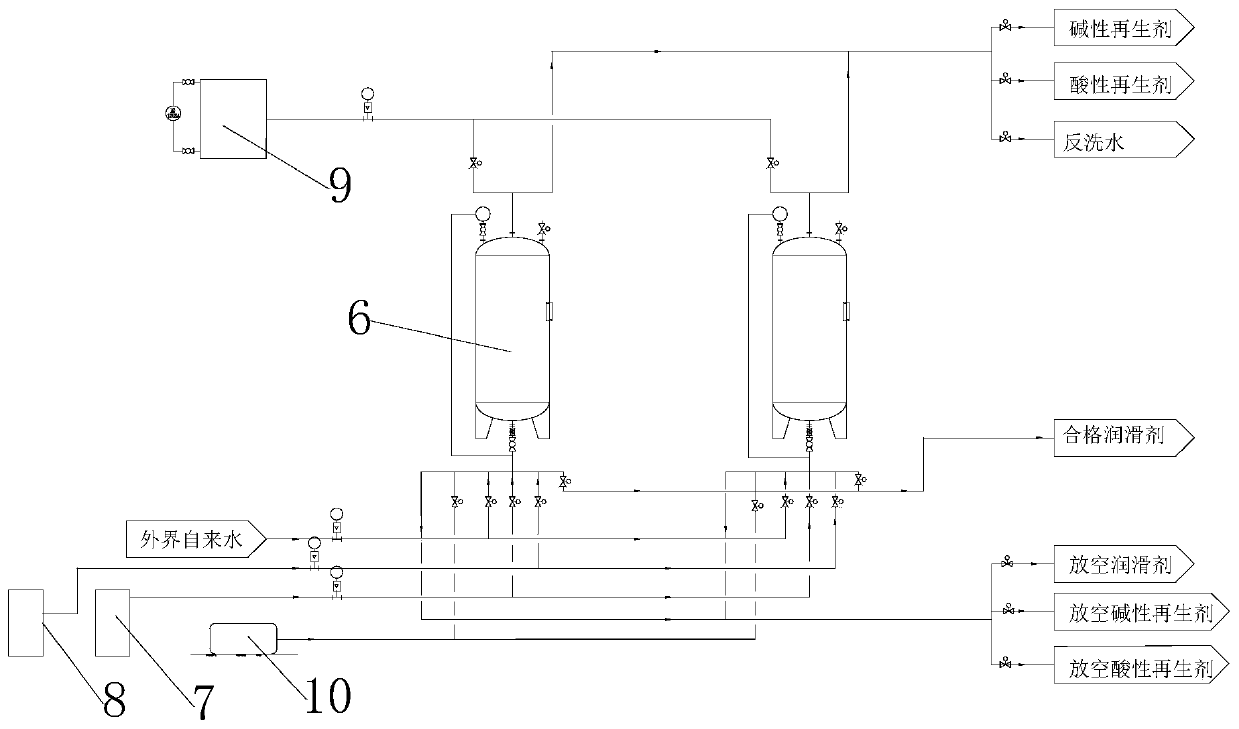

[0033] Such as figure 1 with figure 2 Shown, a kind of regeneration system that contains the emulsion of heavy metal ion, comprises settling tank 1, primary filter 2, secondary filter 3, tertiary filter 4 that are communicated with pipeline successively; Storage tank 9 and solid phase extraction Tower 6; the filtrate outlet of the three-stage filter 4 is communicated with the storage tank 9 through a pipeline, and the liquid outlet of the storage tank 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com