Electroosmosis active waterproofing system and method

An electro-osmotic and active technology, applied in protection devices, buildings, infrastructure engineering, etc., can solve problems such as installation of external machines in outer space, high failure rate of equipment, humidity, and stains, etc., to achieve reasonable structural design and large sensing range , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

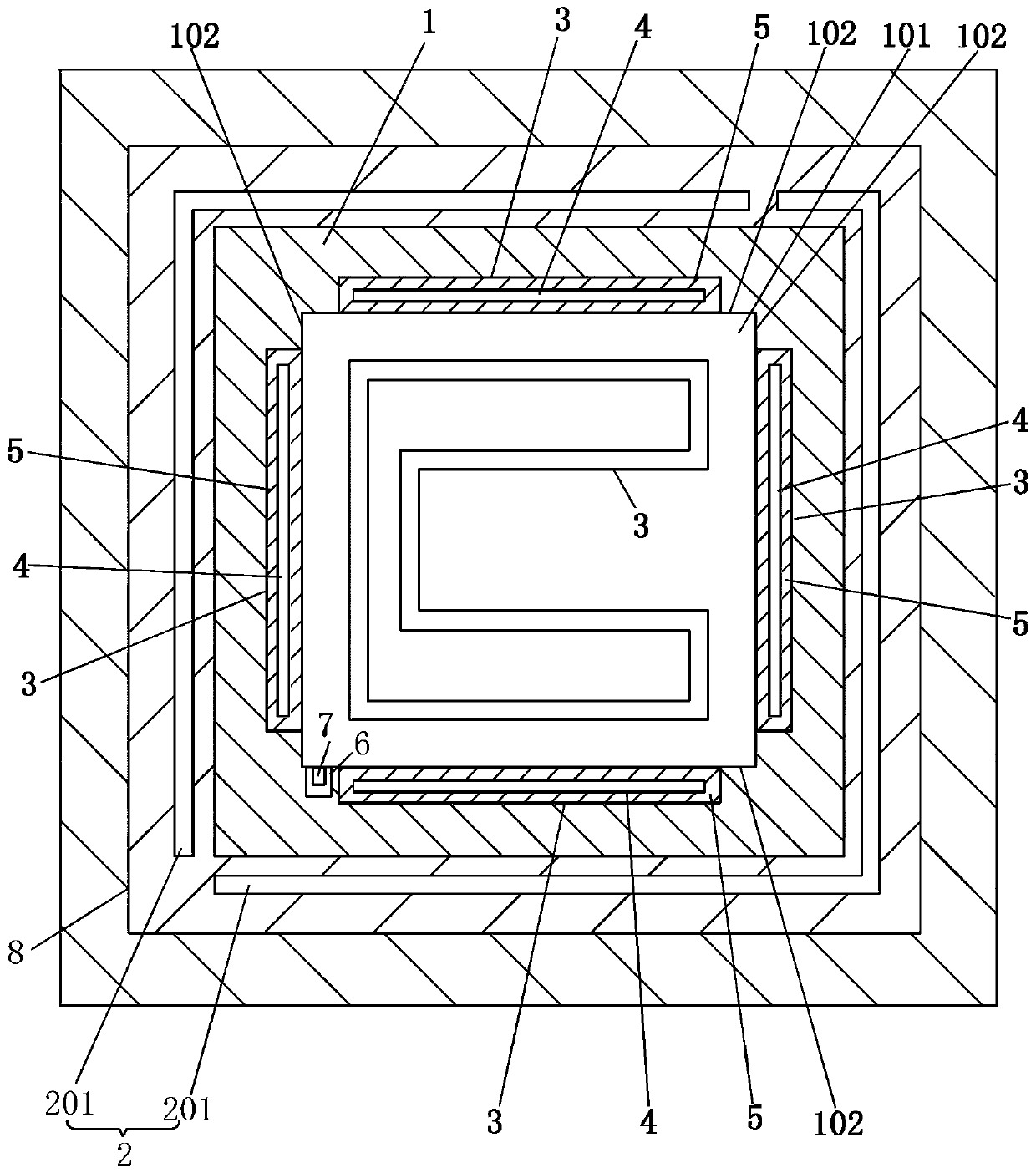

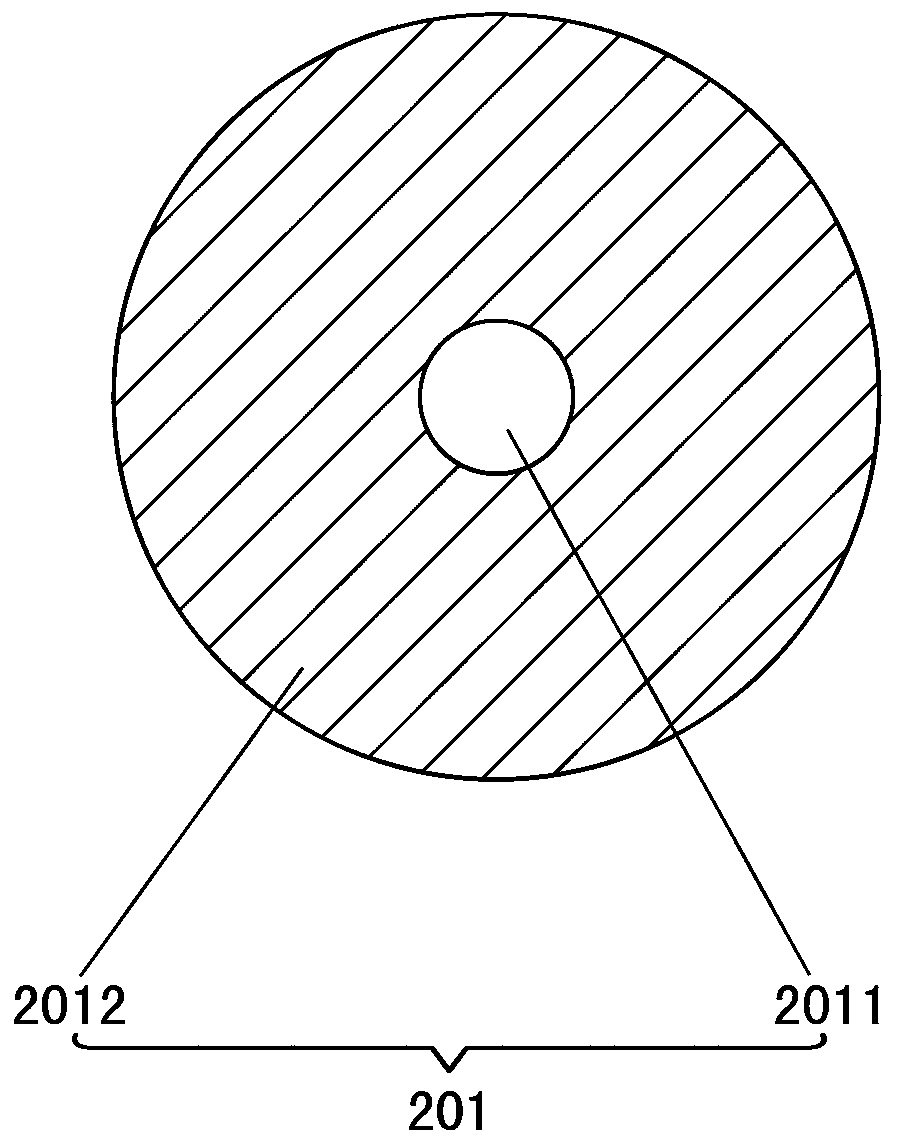

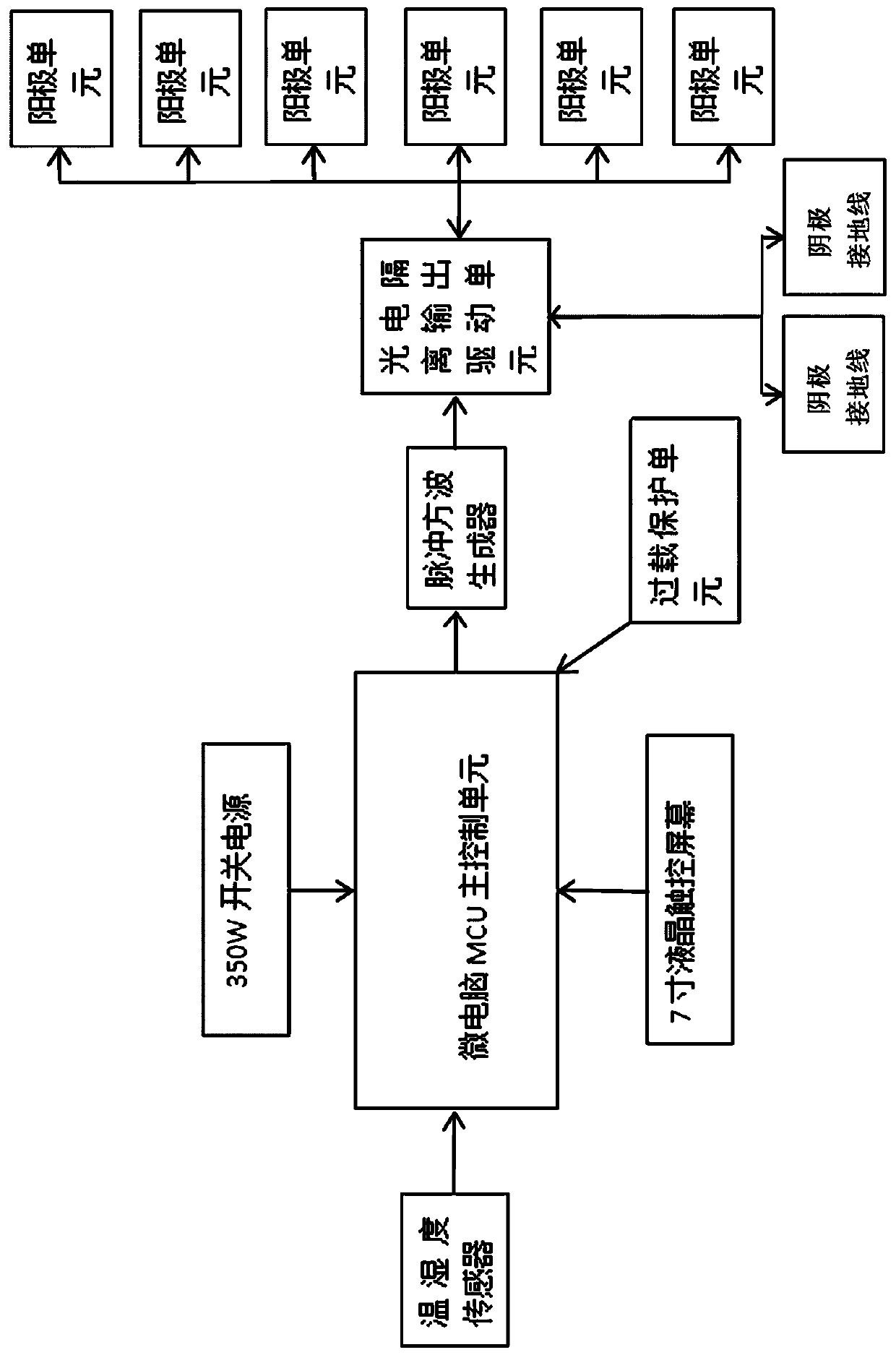

[0031] Such as Figure 1-6 As shown, the electroosmotic active waterproof system in this embodiment includes a cathode unit 2, a temperature and humidity sensor 7, a pulse square wave generator, a switching power supply, a photoelectric isolation output drive unit, a microcomputer MCU main control unit and six anode units 4 The anode unit 4 comprises a plurality of transversely extending titanium wires 401 and a plurality of longitudinally extending titanium wires 401, the transversely extending titanium wires 401 and the longitudinally extending titanium wires 401 are arranged alternately and connected end to end to form a The reciprocating bending planar titanium wire mesh that is continuously curved and extended in an S shape is buried in the anode groove 3 opened on the inner surface of the underground concrete wall 1 that needs to be waterproofed; the cathode unit 2 includes two cathode grounding wires 201 , two cathode grounding wires 201 are buried head to tail in seque...

Embodiment 2

[0062] The difference between the electroosmotic active waterproofing system in this embodiment and the electroosmotic active waterproofing system in Embodiment 1 is that:

[0063] This electro-osmotic active waterproofing system is installed in the tunnel. The underground concrete wall 1 has two wall feet, and the outside of the two wall feet is respectively provided with a cathode trench 8, and a cathode ground wire 201 is arranged in each of the two cathode trenches 8, and each cathode ground wire 201 is connected in parallel with the photoelectric isolation output drive The unit is electrically connected. When the underground concrete wall body 1 belongs to the bottom of the tunnel, it has two wall feet and belongs to this structure.

[0064] The inner surface of the underground concrete wall 1 to be waterproofed includes a bottom surface 101, a top surface and two side surfaces 102. In this embodiment, the bottom surface 101, the top surface ( figure 2 (not visible in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com