Permanent magnet transmission device with water-cooled heat dissipation device

A technology of permanent magnet transmission and heat dissipation device, which is applied in the direction of cooling/ventilation device, permanent magnet clutch/brake, electromechanical device, etc., which can solve the problem of poor adaptability and maintenance-free performance, backward system adjustment mode, and mismatched system Reasonable and other issues, to achieve the effect of preventing heat conduction, low maintenance and maintenance costs, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

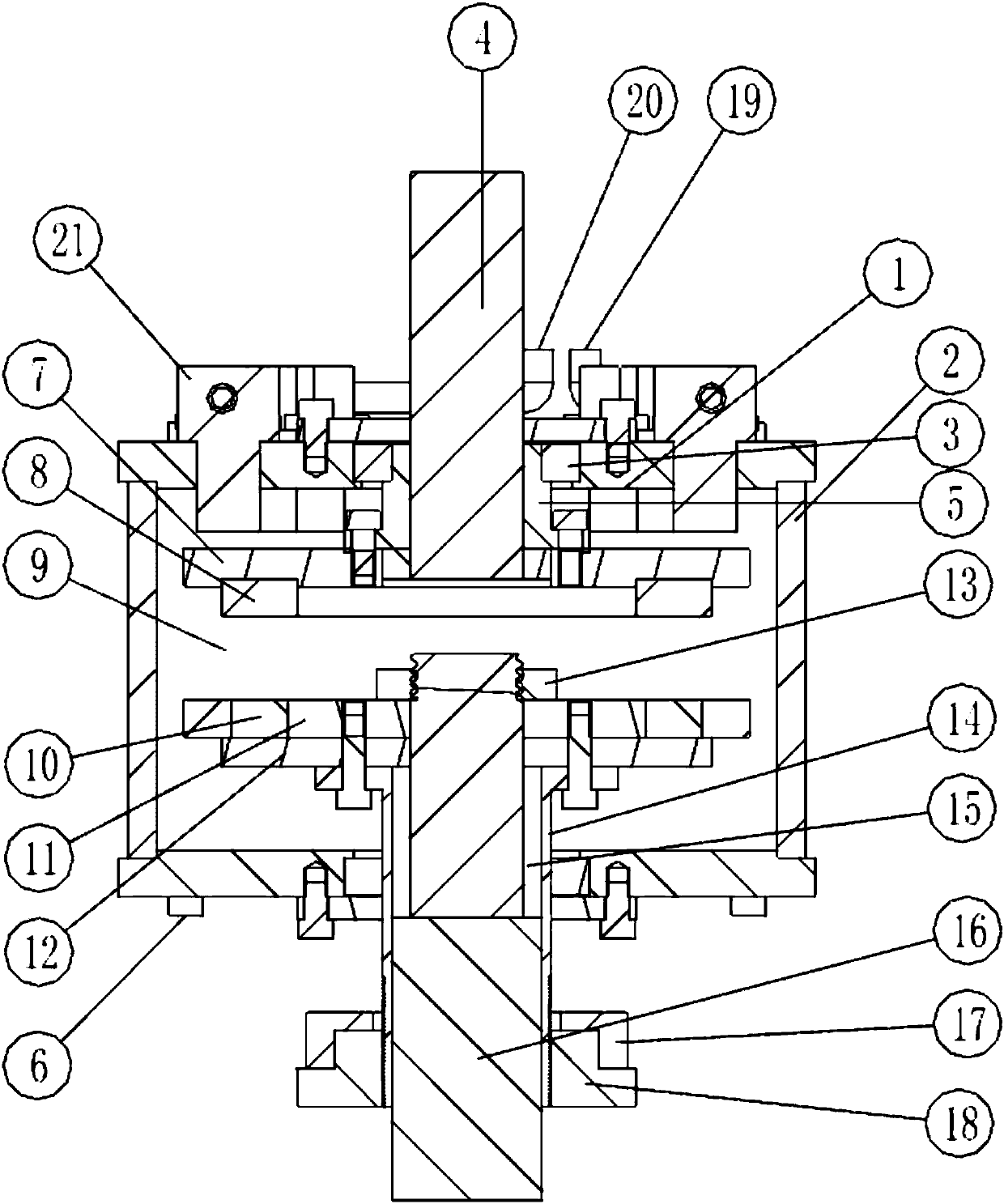

[0018] Such as figure 1 Shown is the device structure diagram of the present invention.

[0019] A water-cooled magnetic transmission energy-saving device, which includes active copper rotor components 7, 8 mounted on the drive shaft 4, permanent magnet rotors 10, 11, 12 assemblies mounted on the driven shaft 15, 16, and a lead screw adjuster 14, 17, 18. The active copper rotor is composed of a disc-shaped steel frame 7 and a copper conductive ring 8, and the copper conductive ring is installed on the surface of the steel plate. Permanent magnets 10 are inlaid on opposite surfaces of the permanent magnet rotor and the active copper rotor. There is an adjustable axial air gap 9 between the opposing surfaces of the active copper rotor and the permanent magnet rotor, and the two are coupled together through magnetic force. When the active cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com