UV-resistant BMC material used outdoors and preparation method of material

A UV-resistant, outdoor technology, applied in the field of BMC materials, can solve problems such as unfavorable promotion and application, and achieve the effects of good storage, good compatibility, increased surface finish and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

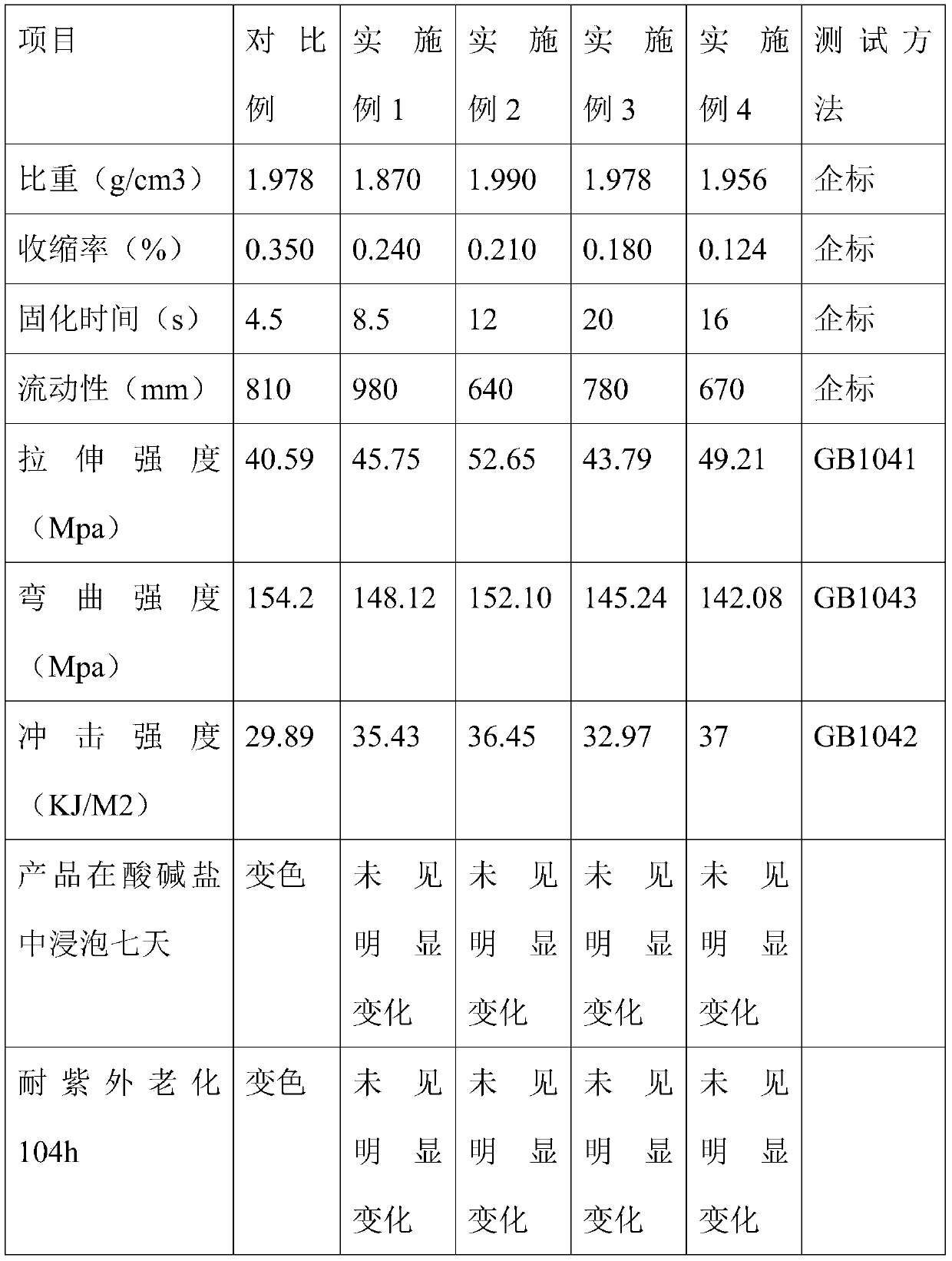

Examples

Embodiment 1-4

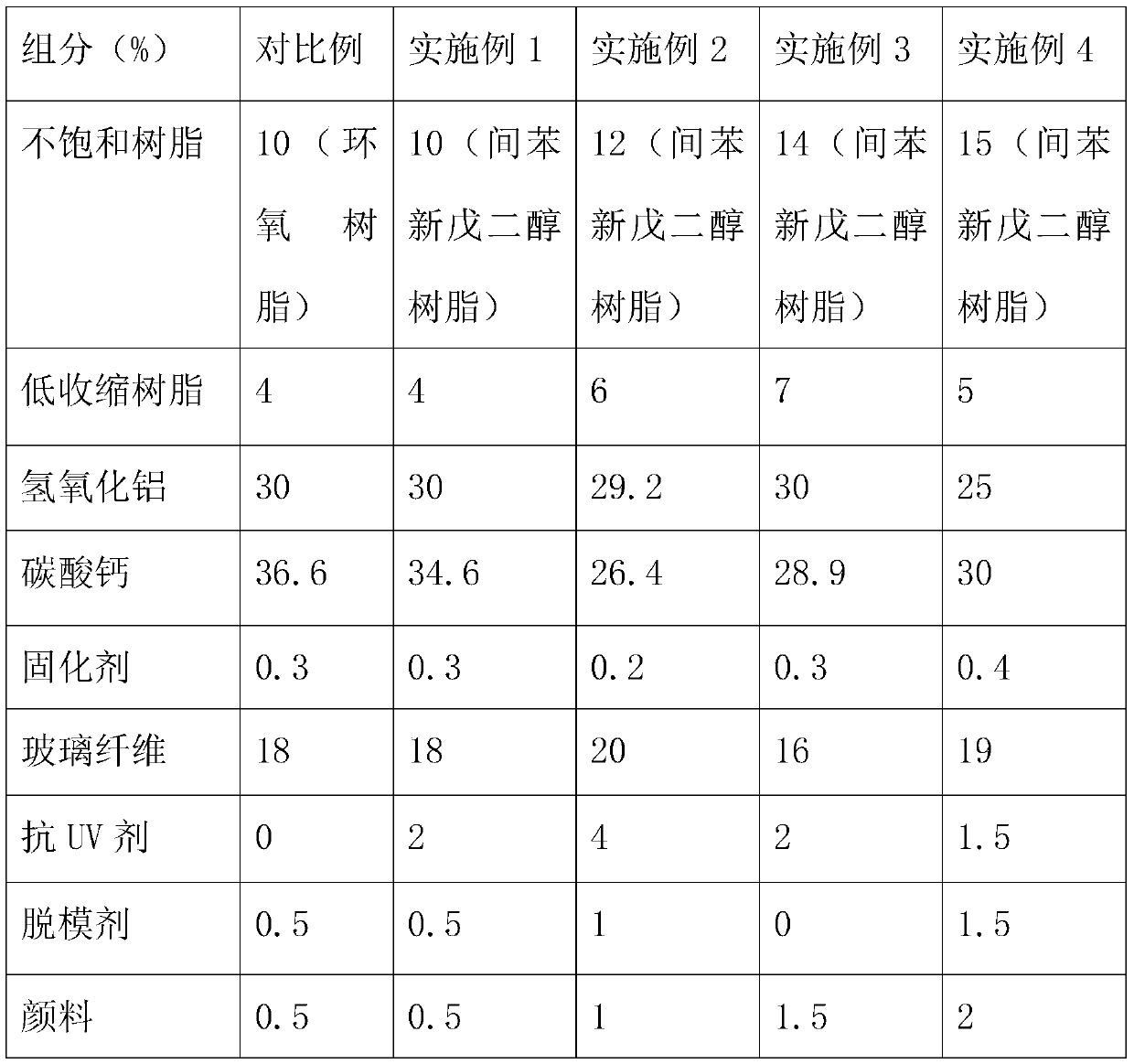

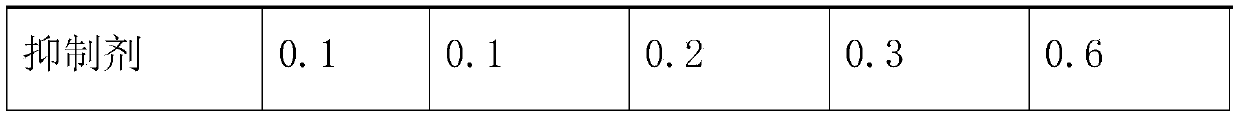

[0026] A UV-resistant BMC material for outdoor use, including unsaturated resin of 4 mass ratio components as shown in the following table, low shrinkage resin, aluminum hydroxide, calcium carbonate, curing agent, glass fiber, anti-UV agent, mold release agent , pigments, inhibitors.

[0027] A method for making an ultraviolet-resistant BMC material for outdoor use, comprising the steps of:

[0028] Step 1: Add resin, curing agent, anti-UV agent, release agent, and pigment into the dispersion tank, disperse and stir for 15-25 minutes, and obtain a uniformly mixed liquid.

[0029] Step 2: Add calcium carbonate and aluminum hydroxide into the kneader and stir for 10-20 minutes to obtain a uniformly stirred powder.

[0030] Step 3: Add the liquid in Step 1 to the powder in Step 2, and stir in a kneader for 10-30 minutes to obtain a uniformly mixed paste;

[0031] Step 4, evenly add glass fiber to the paste in step 3, stir for 5-15 minutes, and obtain a mixed material product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com