Hot-rolled steel sheet pile and its production method

A technology of hot-rolled steel plates and production methods, which can be applied to sheet pile walls, buildings, and infrastructure engineering, etc., and can solve problems such as high prices, hazards in use, waste of resources, etc., to ensure purity and continuity, and reduce production cost, the effect of guaranteeing extended performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

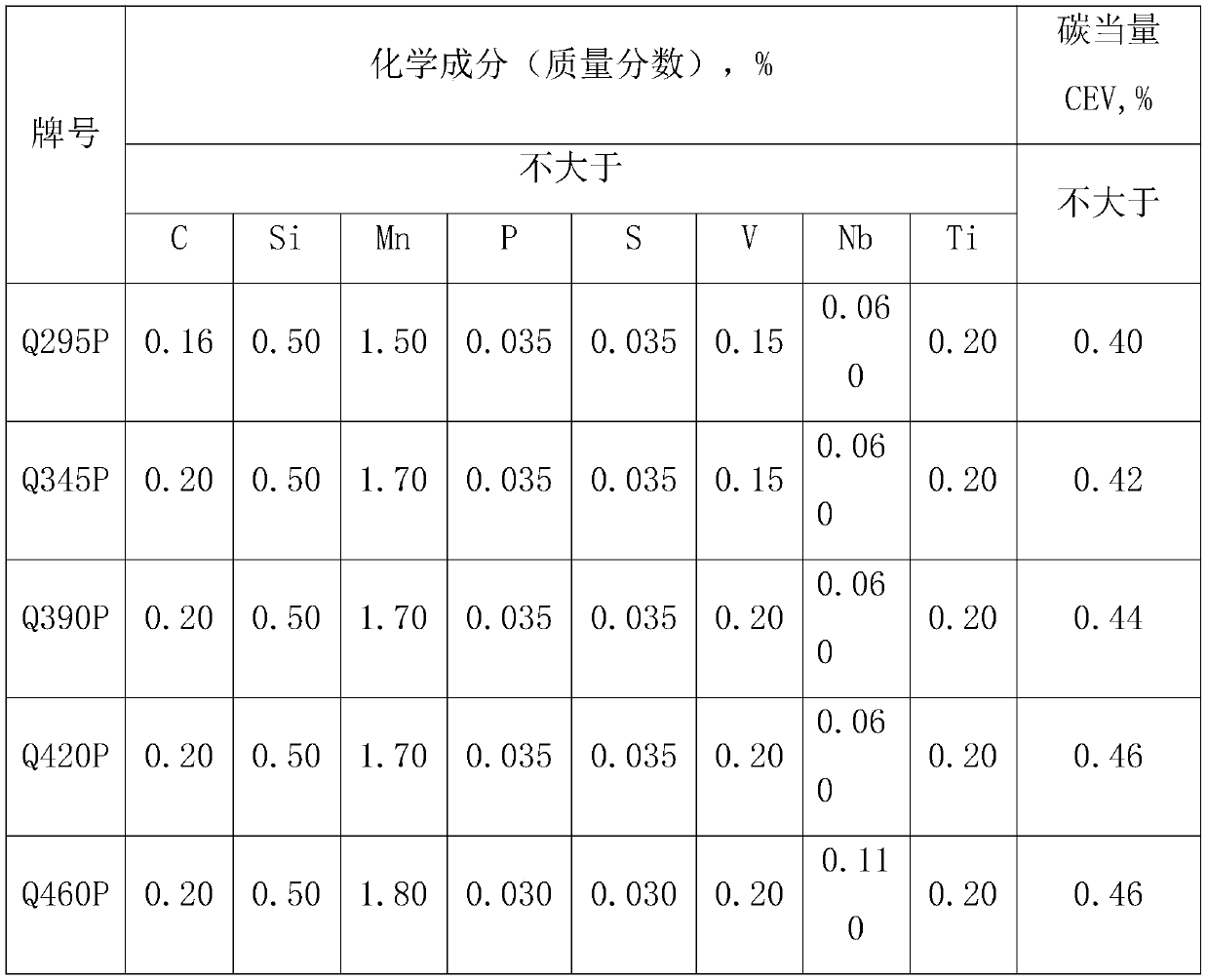

[0042] Example 1: Preparation of hot-rolled steel sheet piles with grade Q295P

[0043] The chemical composition and weight percentage of the steel are: C 0.30%, Si 0.17%, Mn 0.77%, P 0.019%, S0.010%, and the rest are Fe and unavoidable impurities.

[0044] Its production method comprises the following steps:

[0045] (1) Converter or electric furnace smelting; during smelting, the tapping temperature of smelting is controlled to be 1620-1660°C.

[0046] (2) Refining in the refining furnace; control the basicity of the slag to be greater than 3.0.

[0047] (3) Continuous casting and casting; the tundish temperature of the continuous casting machine is 1500-1530°C, the superheat of the tundish is controlled at 20-30°C, and the casting speed is 0.6-0.8m / min.

[0048] (4) Steel billet heating; when the steel billet is heated, the temperature of the steel rolling heating furnace is 1250-1300°C.

[0049] (5) The finished steel sheet pile is obtained by hot rolling; the hot rolli...

Embodiment 2

[0050] Example 2: Preparation of hot-rolled steel sheet piles with grade Q345P

[0051] The chemical composition and weight percentage of the steel are: C 0.32%, Si 0.16%, Mn 0.77%, P 0.023%, S0.019%, and the rest are Fe and unavoidable impurities.

[0052] Its production method comprises the following steps:

[0053] (1) Converter or electric furnace smelting; during smelting, the tapping temperature of smelting is controlled to be 1620-1660°C.

[0054] (2) Refining in the refining furnace; control the basicity of the slag to be greater than 3.0.

[0055] (3) Continuous casting and casting; the tundish temperature of the continuous casting machine is 1500-1530°C, the superheat of the tundish is controlled at 20-30°C, and the casting speed is 0.6-0.8m / min.

[0056] (4) Steel billet heating; when the steel billet is heated, the temperature of the steel rolling heating furnace is 1250-1300°C.

[0057] (5) The finished steel sheet pile is produced by hot rolling; the hot rolli...

Embodiment 3

[0058] Example 3: Preparation of hot-rolled steel sheet piles with the grade Q390P (please add the amount of each element below)

[0059] The chemical composition and weight percentage of the steel are: C 0.37%, Si 0.15%, Mn 0.85%, P 0.018%, S0.018%, and the rest are Fe and unavoidable impurities.

[0060] Its production method comprises the following steps:

[0061] (1) Converter or electric furnace smelting; during smelting, the tapping temperature for smelting is controlled to be 1610-1650°C.

[0062] (2) Refining in the refining furnace; control the basicity of the slag to be greater than 3.0.

[0063] (3) Continuous casting and casting; the tundish temperature of the continuous casting machine is 1490-1520°C, the superheat of the tundish is controlled at 20-30°C, and the casting speed is 0.5-0.75m / min.

[0064] (4) Steel billet heating; when the steel billet is heated, the temperature of the steel rolling heating furnace is 1230-1280°C.

[0065] (5) The finished steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com