Flue gas white-smoke eliminating system of heating boiler

A heating boiler and flue gas technology, applied in the field of flue gas whitening system and hot water heating boiler, can solve the problems of inconvenient chimney discharge, affecting the discharge efficiency and discharge effect, etc., to eliminate water molecules, avoid air pressure fluctuations, and improve smoke The effect of air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

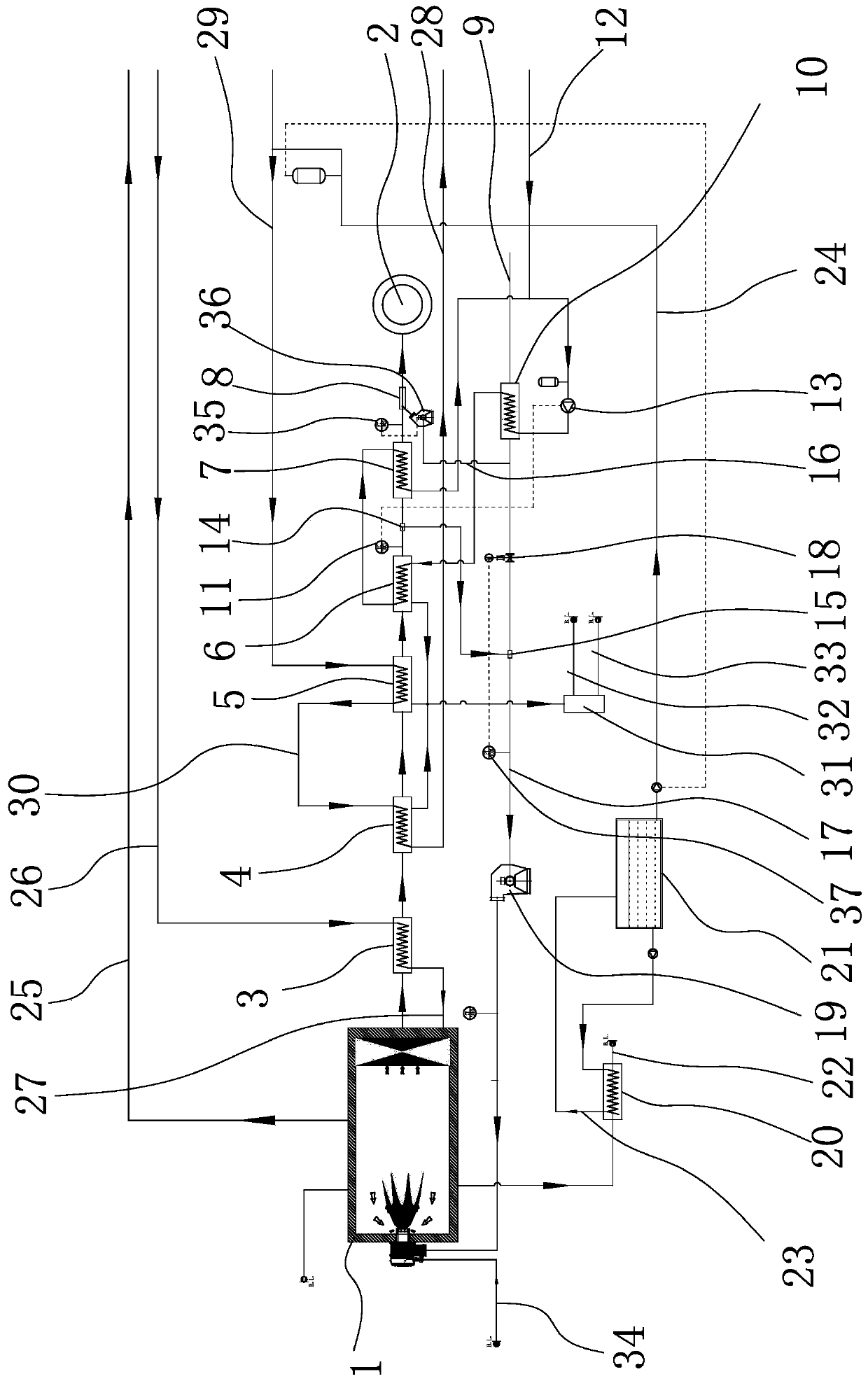

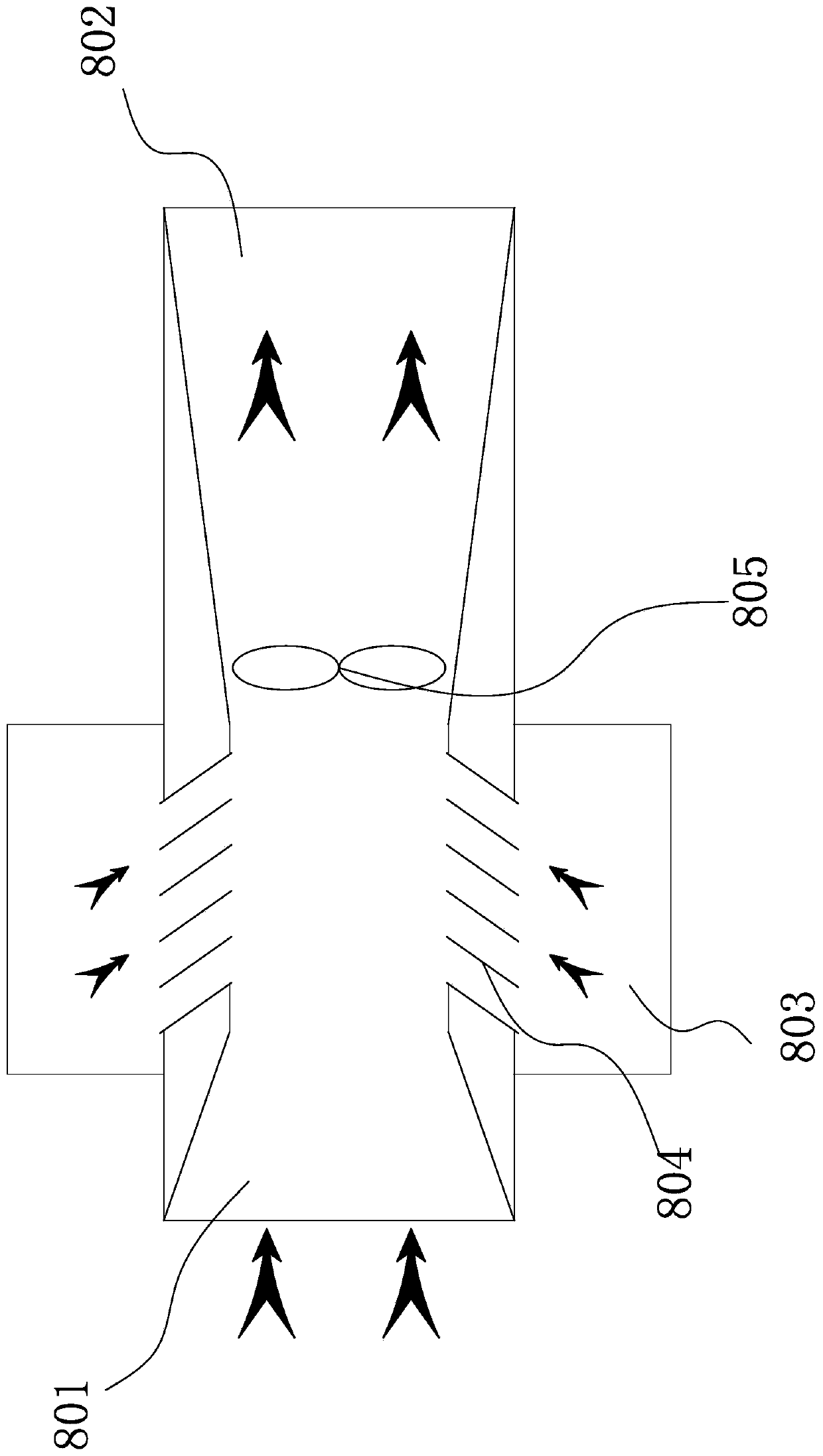

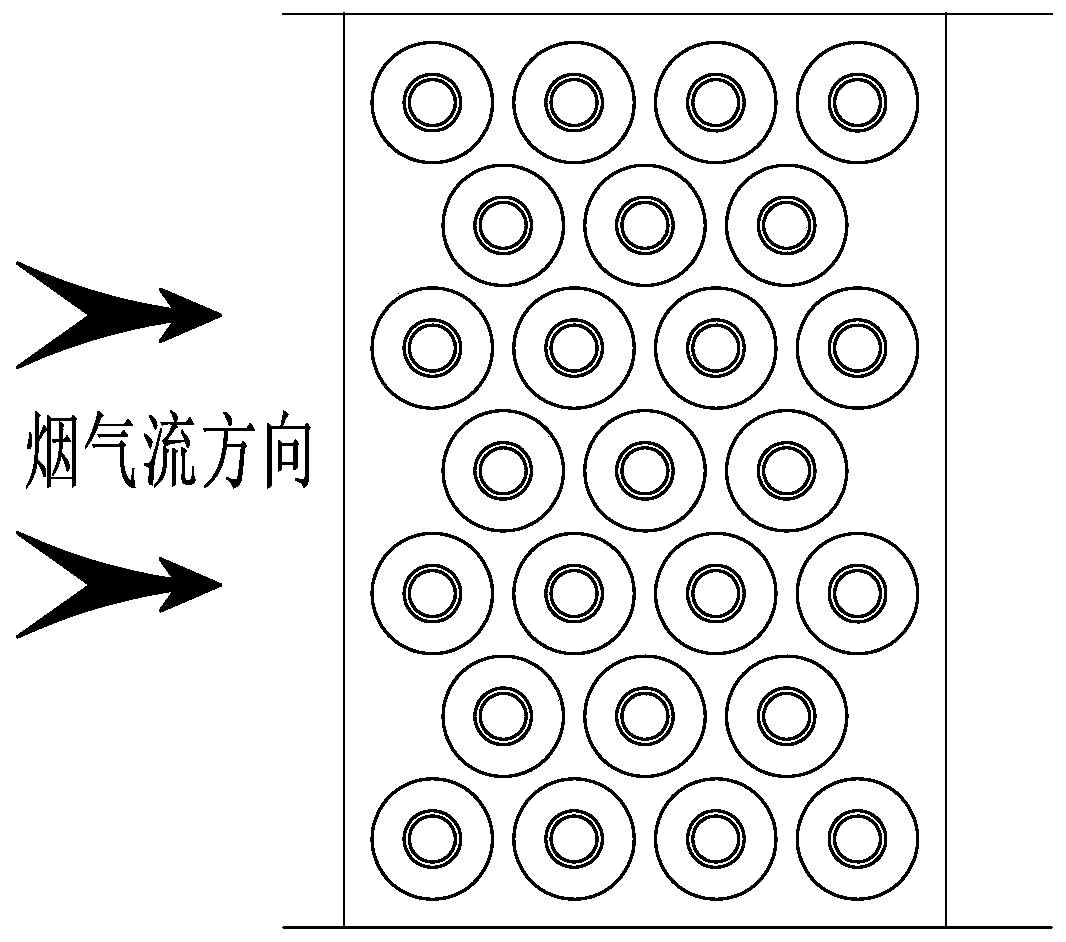

[0031] refer to figure 1, this embodiment is a flue gas whitening system for heating boilers, including a boiler body 1 and a chimney 2, a natural gas supply pipeline 34 is connected to the boiler body 1, and a first-level energy-saving 3, secondary economizer 4, condenser 5, condensing device 6, preheating whitening device 7, mixing speed increasing device 8 and chimney 2, a primary heating water circulation pipeline is set between the boiler body 1 and primary economizer 3 , a secondary heating water circulation pipeline is arranged between the secondary economizer 4 and the condenser 5, and an air pipeline 9 that introduces preheated air through an induced draft fan 36 is connected to the mixing speed increasing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com