A measurement and analysis implementation system and method of beam quality factor based on labview

A beam quality, measurement and analysis technology, which is applied in the measurement and analysis implementation system and field of beam quality factor based on labview, can solve the problems of ActiveX execution instability, unfavorable development, and troublesome operation, and achieves easy development and maintenance. Debugging, easy to test the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

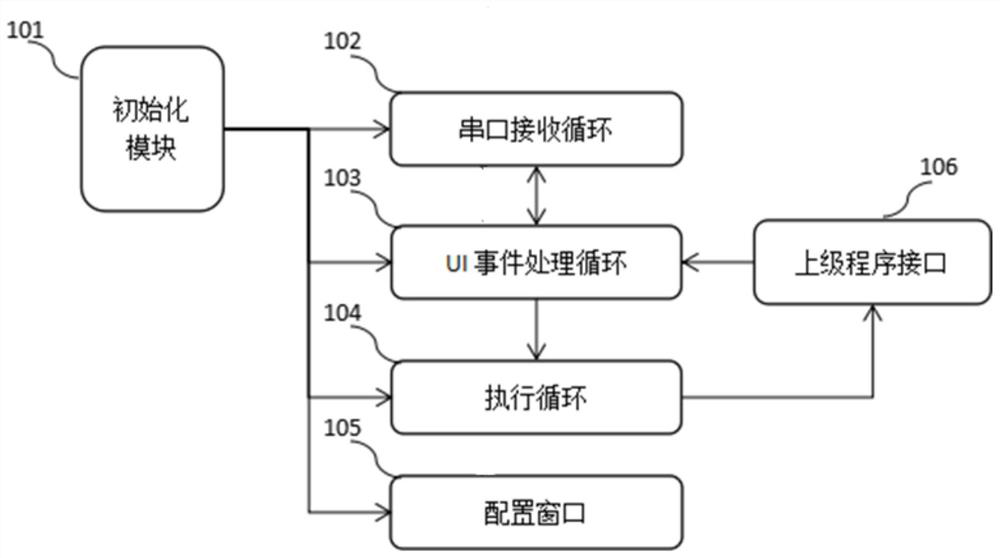

[0083] This embodiment provides a labview-based system for realizing the measurement and analysis of the beam quality factor. The software program adopts the developed labview program, and the hardware adopts a typical measurement system. The system is composed of an adjustable attenuation system, a focusing mirror, a mirror, an automatic guide rail, and a CCD / CMOS beam analyzer. The laser is in the measurement system. After the reflector reaches the camera, the beam diameter at different distance positions is measured by moving the reflector to control the optical path. Among them, the attenuation system and the automatic guide rail are connected with a single-chip microcomputer, and the single-chip microcomputer and the camera are connected with the upper computer. Such as figure 1 As shown, the method of using this system to realize the measurement and analysis of the beam quality factor based on labview is as follows:

[0084] S1. When the upper-level program is running,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com