A method for automatic temperature measurement and sampling of steelmaking converter door

A steel-making converter and furnace door technology, applied in the metallurgical field, can solve the problems of low success rate of automatic temperature measurement and sampling, single-function automatic device, unreasonable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

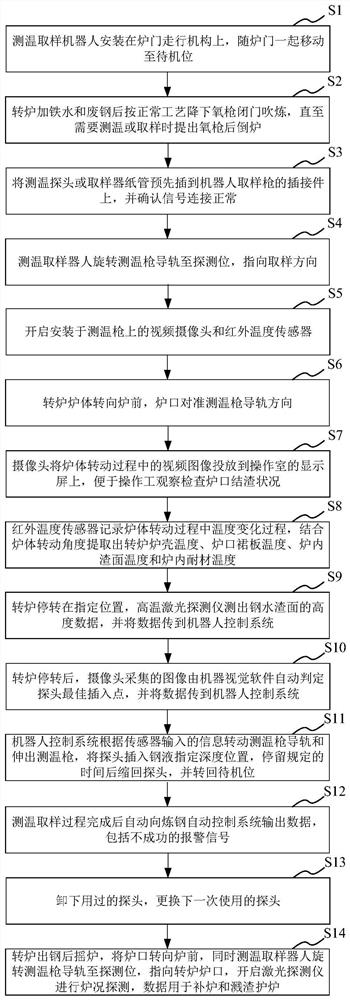

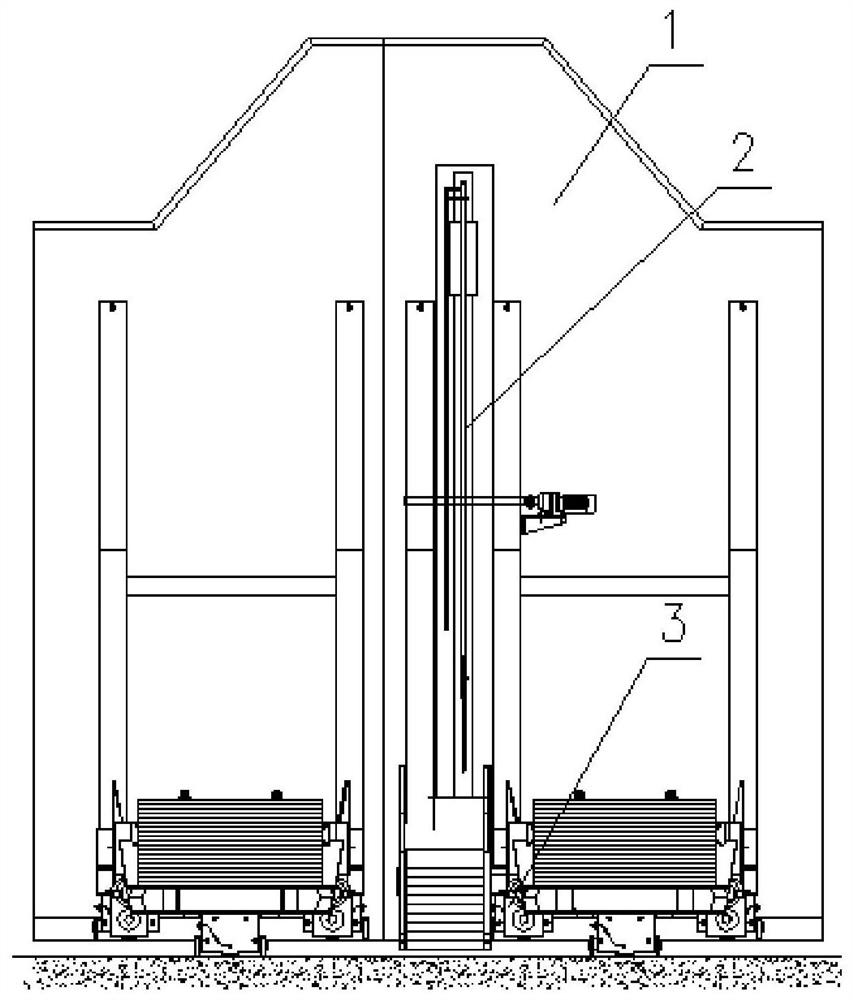

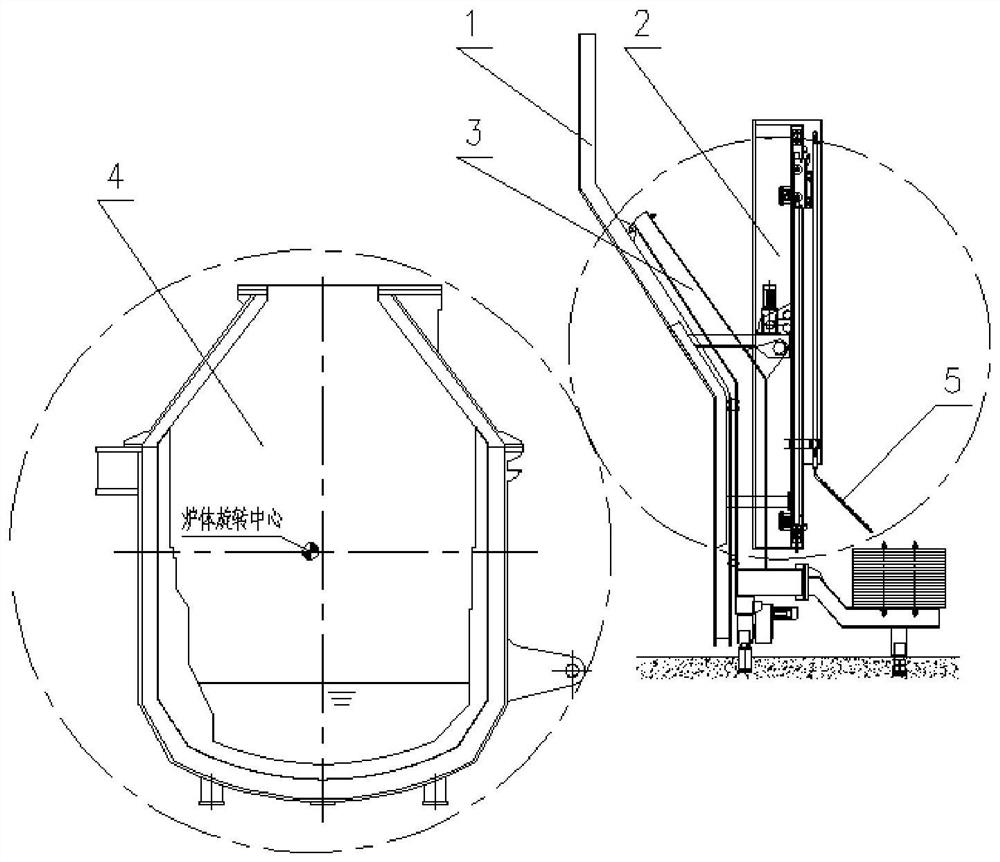

Embodiment 1

[0041]Take the 180tAOD converter metallurgical production of a steel plant as an example. The AOD converter is used to smelt stainless steel, and steel and slag are mixed out, with an average of about 15 furnaces of steel being tapped per day. Its steelmaking process requires six temperature measurement and sampling during the smelting process. Since the slag thickness exceeds 1m in the early stage of smelting, steel samples are often not obtained by the existing sub-lance. The first 5 times have always required manual sampling at the furnace door. However, the AOD converter uses argon-oxygen mixed blowing and stirring on the furnace wall, and molten steel will splash when the furnace is tilted, which will bring obvious hazards to the manual temperature measurement and sampling operation. Warm sampling robot. see figure 1 , a flow chart of a method for automatic temperature measurement and sampling of a steelmaking converter door provided by the invention, specifically as f...

Embodiment 2

[0084] A 100t carbon steel converter in a steel plant does not have sub-gun equipment for the converter due to its small furnace mouth. The temperature measurement and sampling of each furnace needs to be shaken to the front of the furnace. The temperature measurement and sampling operation is performed manually, often facing molten steel splashing danger. Adopt automatic temperature measurement and sampling method of the present invention to replace manual operation, carry out operation according to the following steps:

[0085] 1) The temperature measurement and sampling robot has been installed on the fire door in front of the self-propelled furnace and moves with the furnace door;

[0086] 2) The converter lowers the oxygen lance and blows with the door closed according to the normal process, until the oxygen lance is taken out when temperature measurement or sampling is required, and then the furnace is reversed;

[0087] 3) Manually insert the temperature measuring prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com