Bacillus subtilis wettable powder and preparation process thereof

A technology for Bacillus subtilis and wettable powder, which is applied to the field of Bacillus subtilis wettable powder and its preparation technology, can solve the problems of inflexible use, single-weight mixing pulverization structure, reduced application scope, etc., and achieves flexible raw material conveying operation. , the effect of increasing the scope of application and improving the efficiency of cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

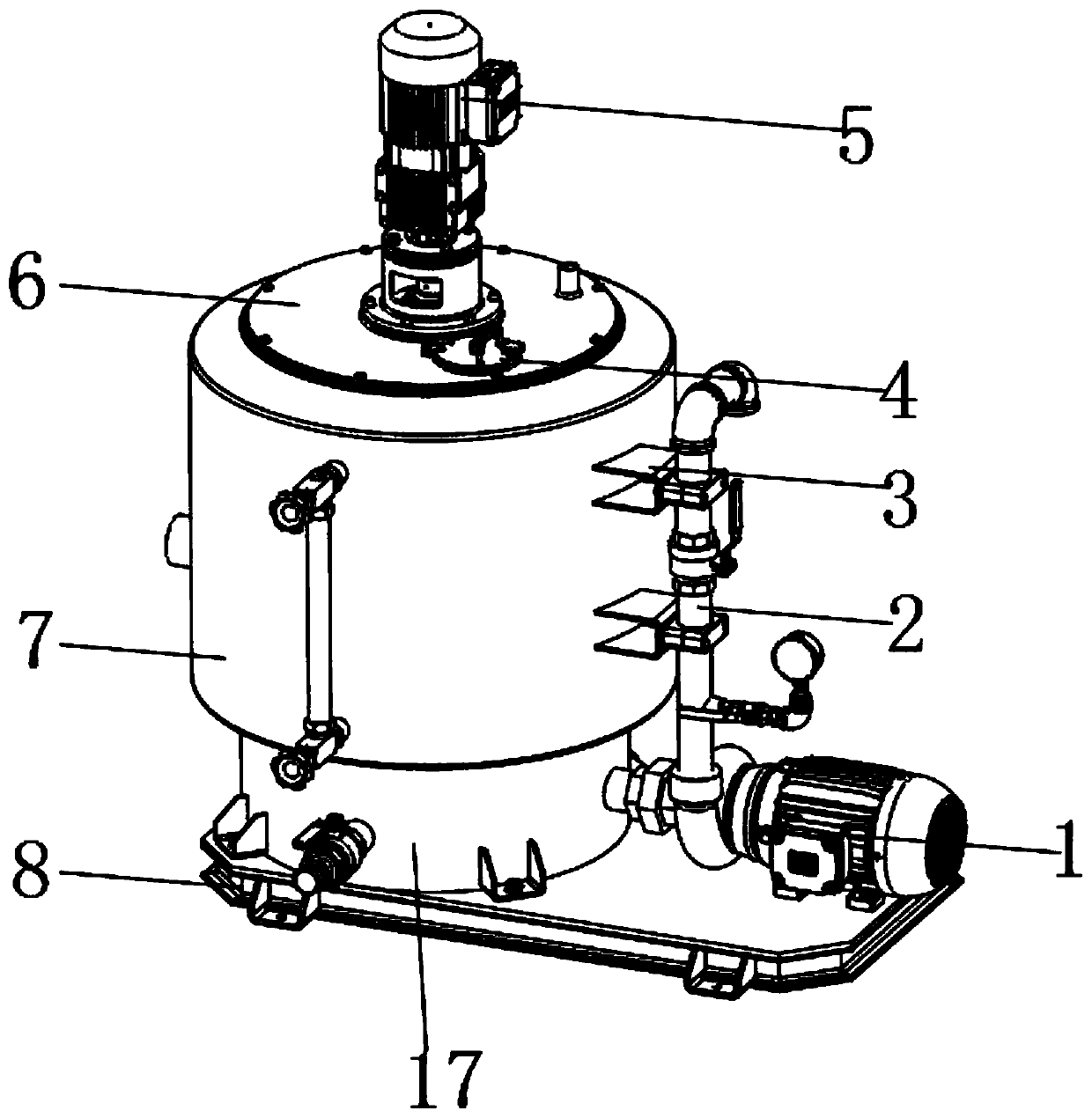

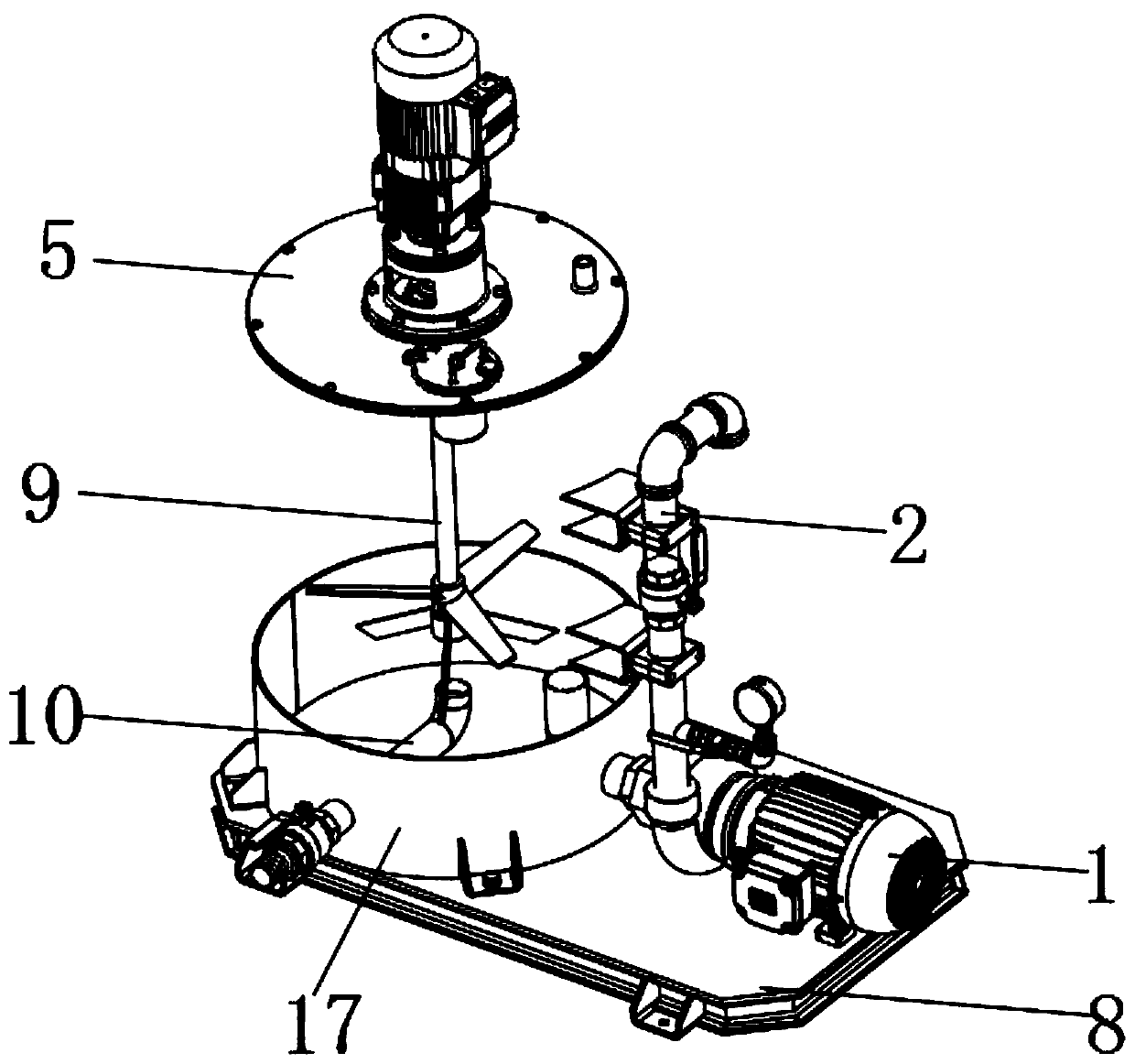

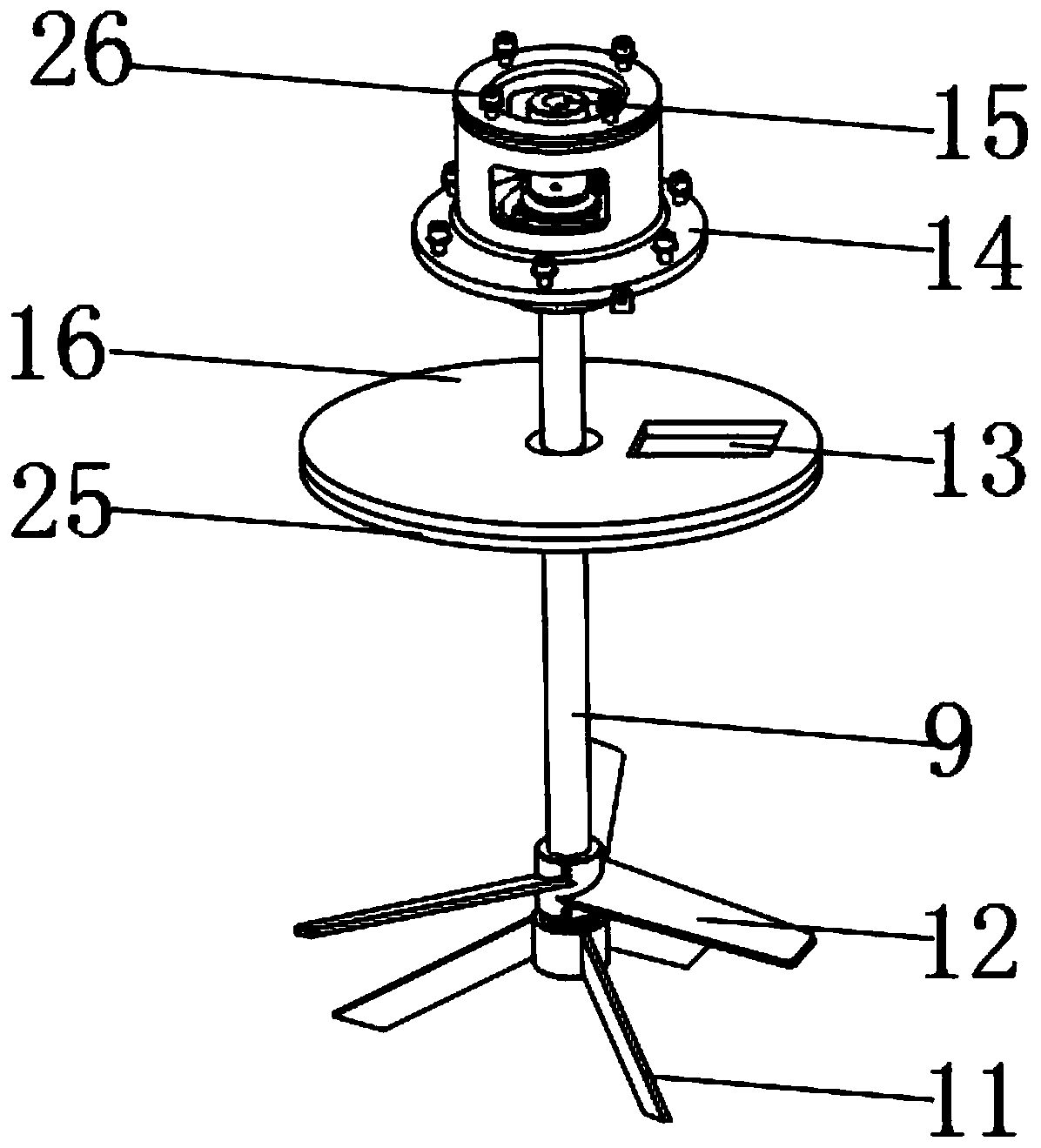

[0042] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0043] A Bacillus subtilis wettable powder, each 1000g wettable powder is prepared from the following raw materials: Bacillus subtilis 800g, distilled water 450g, glucose 250g, peptone 150g, sodium chloride 5g, beef extract 200g, agar 20g;

[0044] Bacillus subtilis is made by the following steps;

[0045] S1: After the strain is cut obliquely, put it into a test tube containing liquid complete medium in sheet form;

[0046] S2: Heat the test tube to 37°C, shak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com