A centralized collection and disposal system for leaked chlorine gas

A disposal system and chlorine gas technology, applied in gas treatment, separation method, dispersed particle separation, etc., can solve the problem of increasing the difficulty of cleaning the lye absorption tank, and achieve the effect of reducing the frequency and difficulty of cleaning, solving pollution, and avoiding physical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

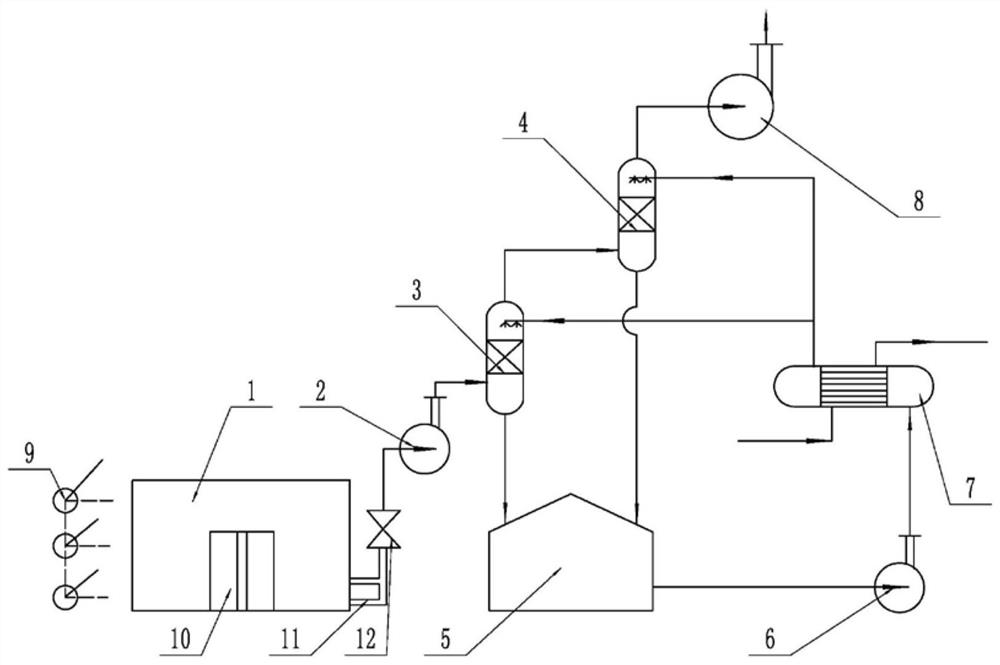

[0028] A chlorine leakage treatment system consists of an accident treatment room 1, an accident fan 2, a first lye absorption tower 3, a second lye absorption tower 4, an lye circulation tank 5, an lye circulation pump 6, an lye cooler 7, Vacuum pump 8 and flammable and poisonous alarm instrument 9 are implemented in combination. The accident treatment room 1 is composed of a main structure, a passage port 10, a gas outlet pipe 11 and an outlet pipe control valve 12, which can realize the centralized collection of leaked chlorine gas caused by the failure of the bottle body structure during the vaporization process. Functional relatively closed space structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com