Diphenylcyclotrisiloxane and its preparation method and application

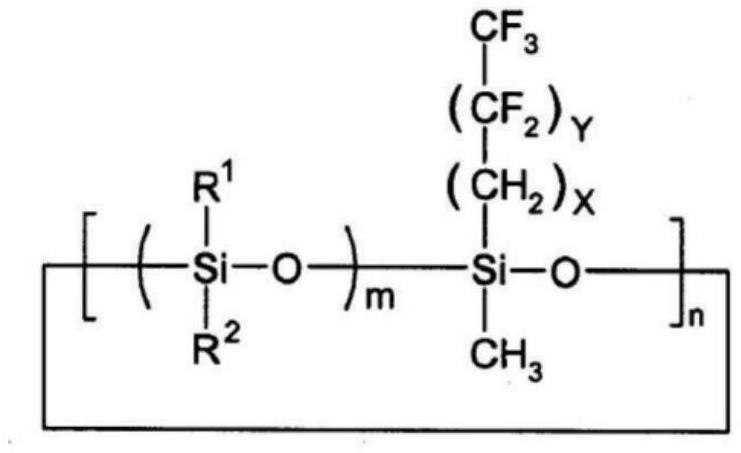

A technology of diphenylcyclotrisiloxane and diphenylsiloxane is applied in the field of synthesis of organosilicon compounds, and can solve the problems of inability to efficiently obtain target products, poor cyclosiloxane selectivity and the like, and achieve copolymerization. The effect of good reaction effect, less impurities and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

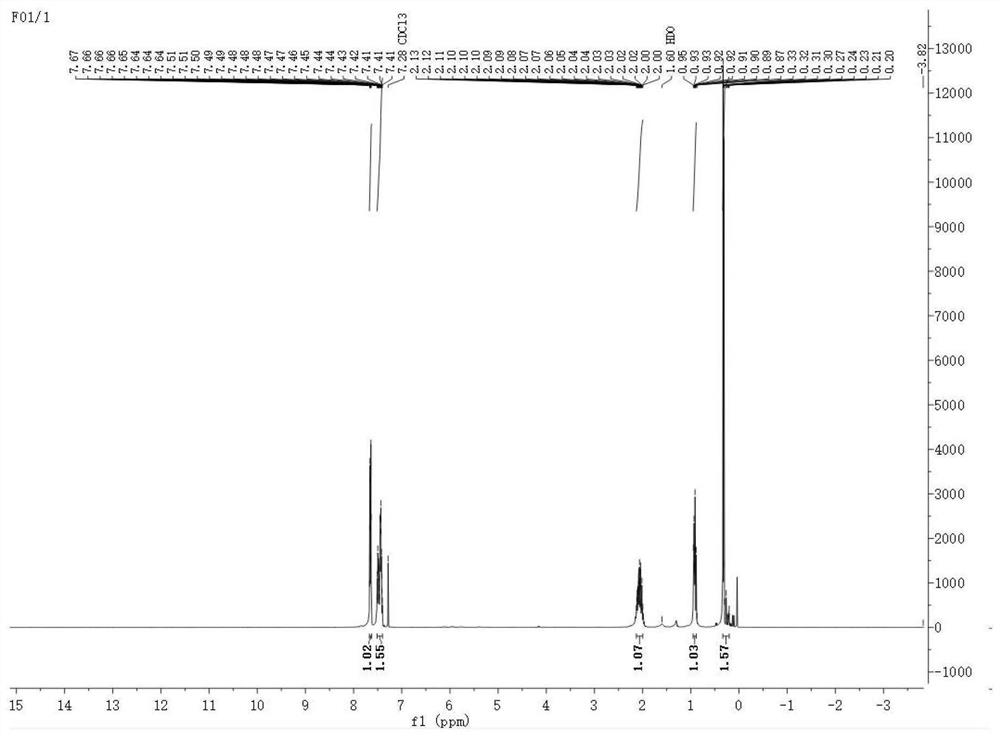

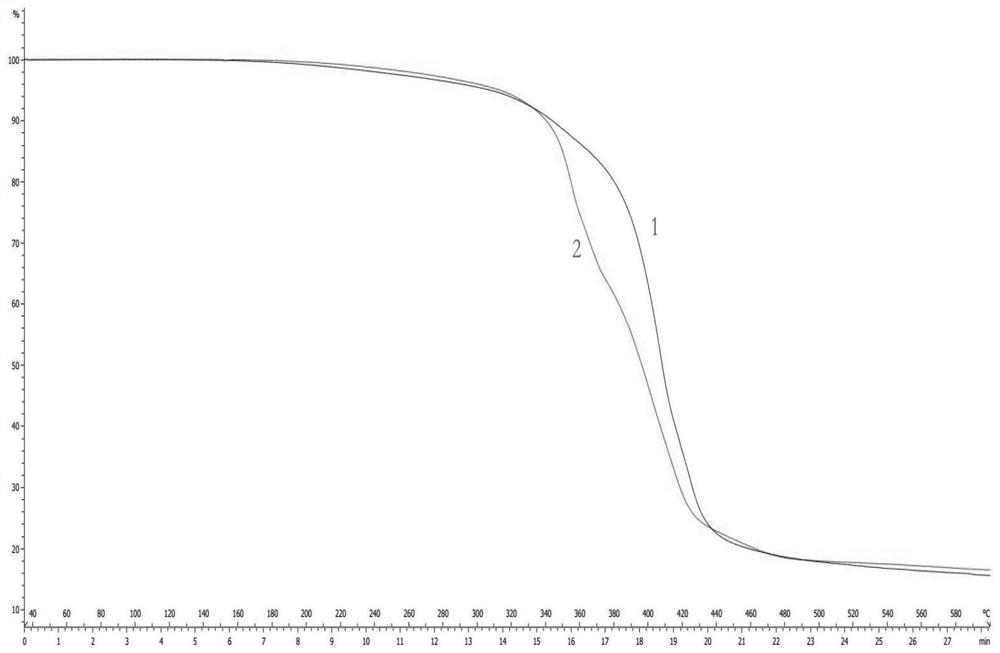

[0049] The preparation method of 1,3-dimethyl-1,3-bis(3,3,3-trifluoropropyl)-5,5-diphenylcyclotrisiloxane comprises the following steps:

[0050] (1) Under nitrogen protection, add 1055g trifluoropropylmethyl dichlorosilane and 540g ethyl acetate to a 5L four-necked flask equipped with a mechanical stirrer, a thermometer, a constant pressure dropping funnel, and a vent tube, and dissolve 1080g acetic acid Ethyl ester, 540g of diphenylsilanediol and 555.5g of triethylamine were mixed uniformly to form a transparent solution and then added to the constant pressure dropping funnel, started stirring, and slowly added the materials in the constant pressure dropping funnel dropwise to the flask, The system is cooled by an ice-water bath, and the reaction is maintained at 0-20°C until the addition of the material is completed, and then kept at 0-20°C and continued to stir for 2h;

[0051] (2) After the reaction is complete, filter the system to remove triethylamine hydrochloride, whe...

Embodiment 2

[0057] The preparation method of 1,3-dimethyl-1,3-bis(3,3,3-trifluoropropyl)-5,5-diphenylcyclotrisiloxane comprises the following steps:

[0058] (1) Under nitrogen protection, add 1107.8g trifluoropropylmethyldichlorosilane and 540g ethyl acetate to a 5L four-necked flask equipped with mechanical stirring, a thermometer, a constant pressure dropping funnel, and a vent tube, and 1080g Ethyl acetate, 540g of diphenylsilanediol and 583.3g of triethylamine were mixed uniformly to form a transparent solution, then added to the constant pressure dropping funnel, started stirring, and slowly added the contents of the constant pressure dropping funnel to the flask , the system is cooled by an ice-water bath, and the reaction is maintained at 0-20°C until the material is added dropwise, and then kept at 0-20°C and continued to stir for 2h;

[0059] (2) After the reaction is complete, filter the system to remove triethylamine hydrochloride, wherein the filter cake is washed with 200 g ...

Embodiment 3

[0064] The preparation method of 1,3-dimethyl-1,3-bis(3,3,3-trifluoropropyl)-5,5-diphenylcyclotrisiloxane comprises the following steps:

[0065] (1) Under nitrogen protection, add 1160.5g trifluoropropylmethyldichlorosilane and 540g ethyl acetate to a 5L four-necked flask equipped with a mechanical stirrer, a thermometer, a constant pressure dropping funnel, and a vent tube, and 1080g Ethyl acetate, 540g of diphenylsilanediol and 611.1g of triethylamine were mixed uniformly to form a transparent solution, then added to the constant pressure dropping funnel, started stirring, and slowly dropped the contents of the constant pressure dropping funnel into the flask , the system is cooled by an ice-water bath, and the reaction is maintained at 5-15°C until the material is added dropwise, and then kept at 5-15°C and continued to stir for 2h;

[0066] (2) After the reaction is complete, filter the system to remove triethylamine hydrochloride, wherein the filter cake is washed with 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com