Viscosity homogenizing/bubble removing integrated device and method for preceramic polymer spinning melt

A technology of ceramic precursors and polymers, which is applied in the fields of spinning solution filtration, filament forming treatment, textiles and papermaking, etc. It can solve the problems of adverse effects of fiber spinning, inability to melt degassing, and degradation of raw silk quality. Achieve the effects of improving the defoaming efficiency and melt viscosity uniformity, reducing the defects of the original fiber, and avoiding chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

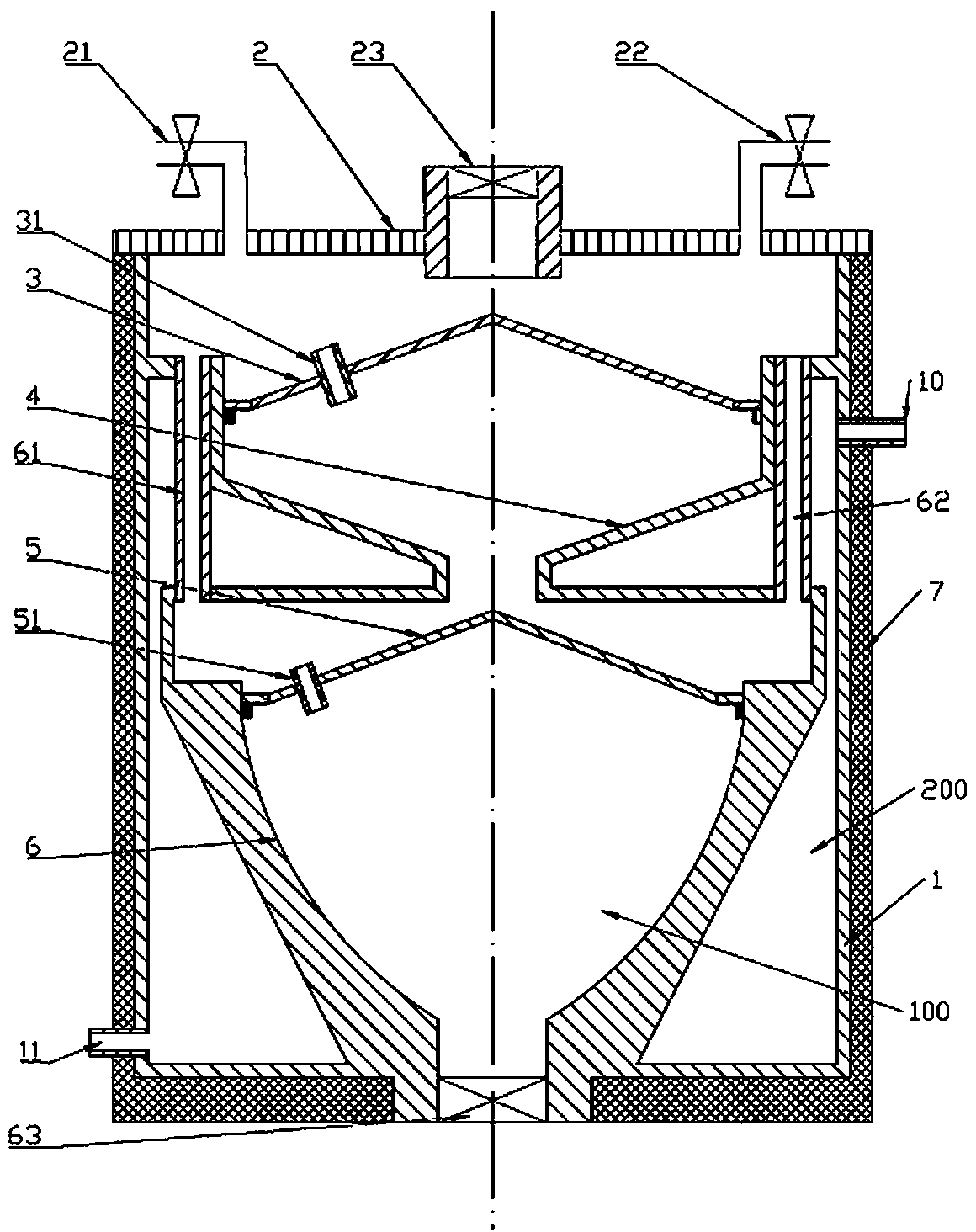

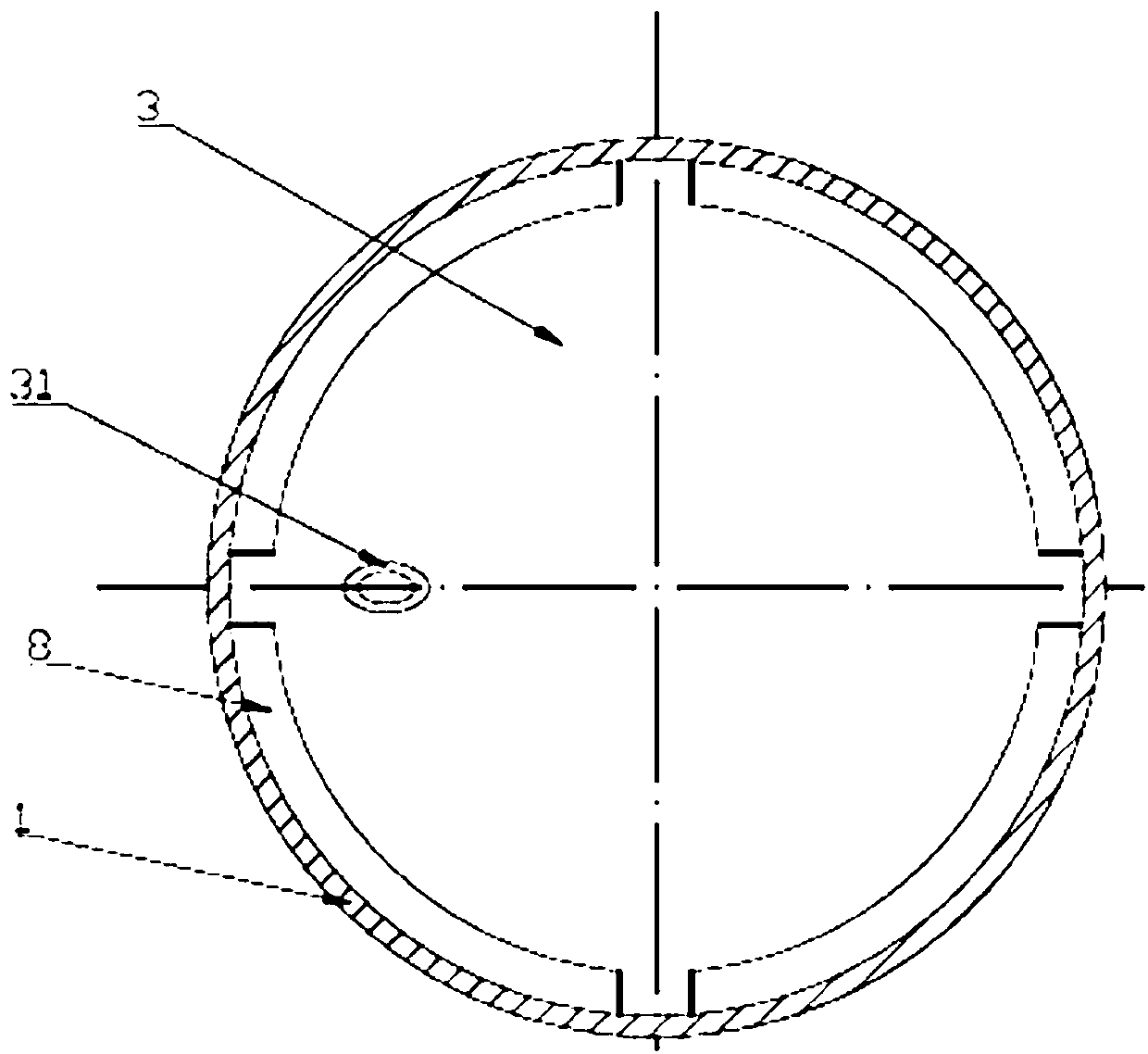

[0035] refer to figure 1 , the uniform viscosity / degassing integrated device of the ceramic precursor polymer spinning melt, comprising a defoaming kettle body 1, the top of the defoaming kettle body 1 is provided with a kettle body upper cover 2, the inner wall surface of the defoaming kettle body 1 and The airtight cavity surrounded by the lower surface of the kettle body upper cover 2 is the inner cavity 100 of the degassing kettle body. Spinning metering pump 63 is provided, and No. 1 umbrella-shaped diversion surface 3, No. 2 anti-umbrella-shaped diversion surface 4, No. 3 umbrella-shaped diversion surface 5, and No. The No. 1 diversion uniform temperature curved surface 6, the No. 1 umbrella-shaped diversion surface 3, the No. 2 anti-umbrella-shaped diversion surface 4, and the No. 3 umbrella-shaped diversion surface 5 are all connected to the inner wall of the degassing kettle body 1, and the No. 1 umbrella-shaped diversion surface The junction of the umbrella-shaped ...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is:

[0054] The melt to be defoamed is the precursor polymer polyaluminocarbosilane (PACS) containing aluminum silicon carbide fibers, and its softening point is 220°C.

[0055] According to the softening point of the polymer to be spun, the temperature of the heat medium in the heat medium inner cavity 200 of the homogenizing / defoaming integrated device is set, the temperature of the heat medium is set to 310° C., and the heat preservation time of the heat medium circulation system is started for 3 hours. When the degree of vacuum in the inner chamber 100 of the degassing kettle of the homogenizing / degassing integrated device is -80kPa, close the valve on the first vacuum connecting pipe 22 . The speed of the feed metering pump 23 was 20 rpm and the pump speed of the spinning metering pump was 19 rpm.

[0056] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com