Controllable diameter-variable and color-ratio-variable coated wire and production method thereof

A production method and technology of covering yarn, which can be used in the production of filaments, textiles, papermaking, yarns, etc., and can solve the problems of lack of appearance and style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

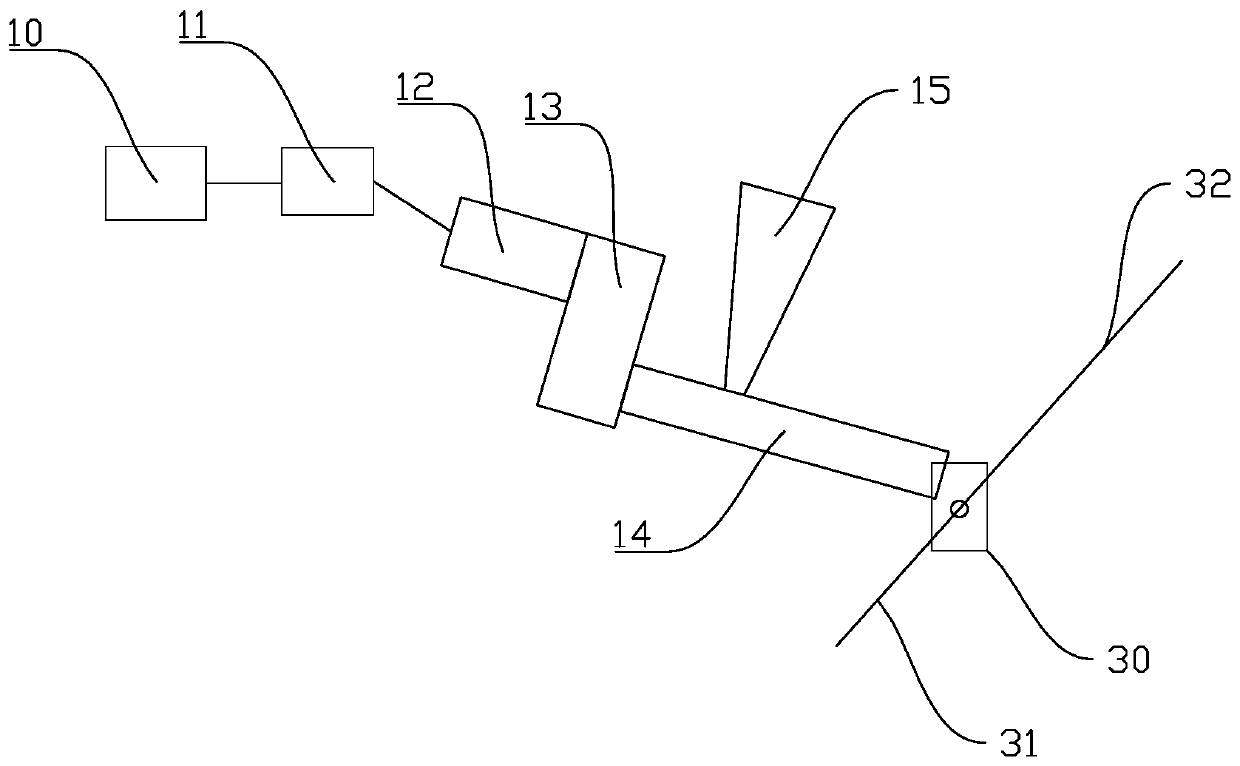

[0032] Control attached figure 1 , the production equipment of embodiment one is: the top of screw extruder is provided with PVC barrel A15, and the screw rod A14 of screw extruder is connected with servomotor A12 through reduction box A13, and described servomotor A12 is connected with programmable PLC controller The servo controller A11 controlled by A10 is connected, the core wire 31 is pulled by the tractor through the diverter 30, the extrusion end of the screw extruder is connected with the diverter 30, and the PVC masterbatch is extruded to the diverter 30 after being heated and plasticized The core wire 31 is wrapped in the middle to obtain the PVC covering wire 32 .

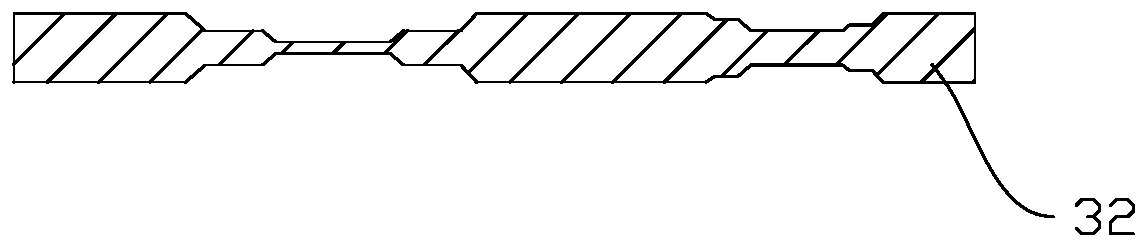

[0033] control figure 2 , the control mode of the screw speed of embodiment one is: based on the screw base speed, 0-15s: 600%; 15-20s: 300%; 20-30s: 100%; 30-35s: 300%; 35-55s : 600%; 55-57s: 500%; 57-65s: 300%; 65-67s: 400%; 67-75s: 600%.

[0034] Gradient adjustment is used when switching between ...

Embodiment 2

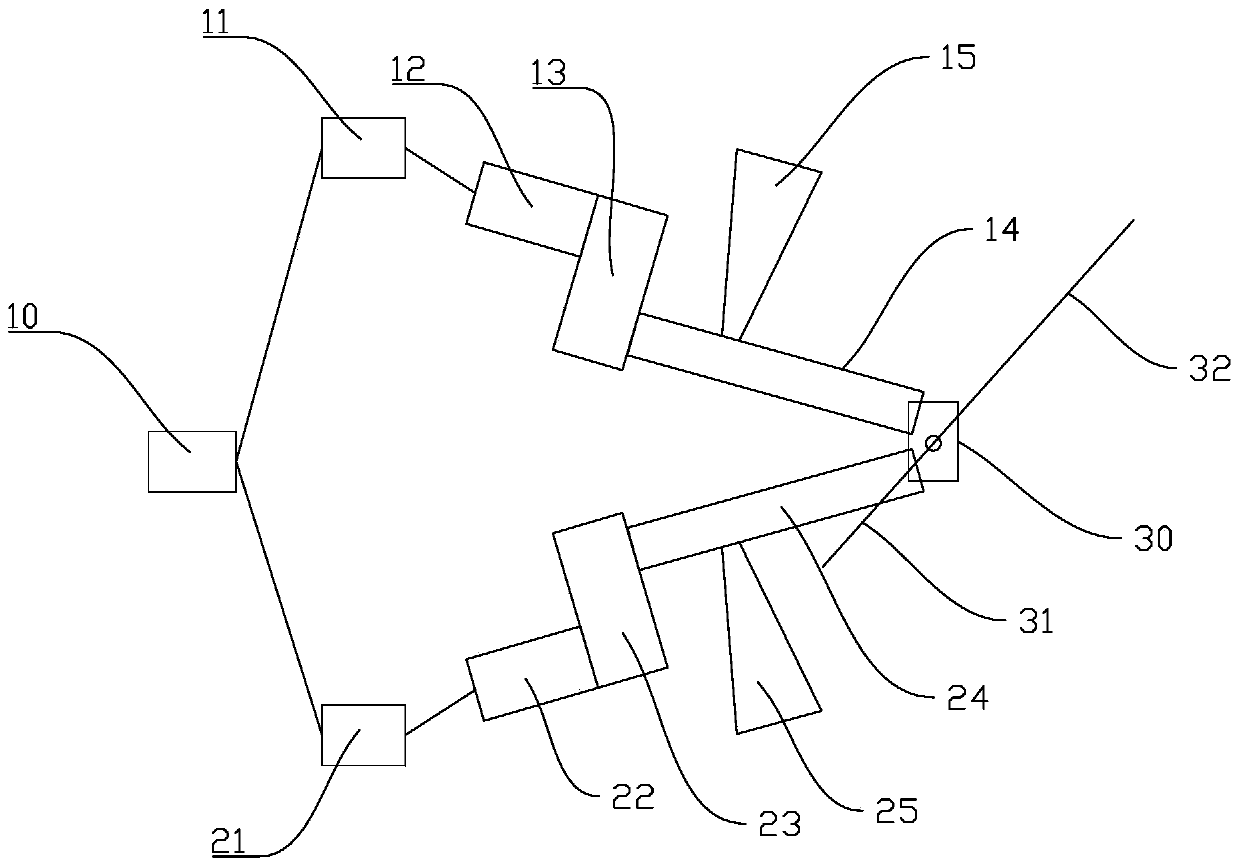

[0036] Control attached image 3 , the production equipment of embodiment two is: comprise two screw extruders, the top of the first screw extruder is provided with PVC barrel A15, the screw rod A14 of screw extruder links to each other with servomotor A12 through reduction box A13, The servo motor A12 is connected with the servo controller A11 controlled by the programmable PLC controller A10, and the top of the second screw extruder is provided with a PVC barrel B25, and the screw B14 of the screw extruder is connected to the servo motor through the reduction box B13. B12 is connected, and the servo motor B12 is connected with the servo controller B11 which is also controlled by the programmable PLC controller A10. The extrusion ends of the two screw extruders are connected with the splitter 30. After melting, extrude into the shunt 30 to wrap the core wire 31 together to obtain the PVC coated wire 32, and the PVC coated wire is composed of the PVC coated wire 32A of the fir...

Embodiment 3

[0040] control attached Figure 5 , the production equipment of embodiment three is: comprise two screw extruders, the top of the first screw extruder is provided with PVC barrel A15, the screw rod A14 of screw extruder links to each other with servomotor A12 through reduction box A13, The servo motor A12 is connected to the servo controller A11 controlled by the programmable PLC controller A10, the PVC barrel B25 is arranged above the second screw extruder, and the screw B14 of the screw extruder is connected to the servo motor through the reduction box B13. B12 is connected, the servo motor B12 is connected with the servo controller B11 controlled by the programmable PLC controller B10, the extrusion ends of the two screw extruders are connected with the flow divider 30, and the two PVC masterbatches are heated and plasticized Extruded into the shunt 30 to wrap the core wire 31 together to obtain the PVC coated wire 32, the PVC coated wire is composed of the PVC coated wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com