System and method for checking gas tightness of soft package battery

An air-tightness inspection and soft-pack battery technology, which is used in liquid/vacuum measurement for liquid tightness and measurement of fluid acceleration and deceleration rates. problem, to reduce the space formed, facilitate rapid pumping, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

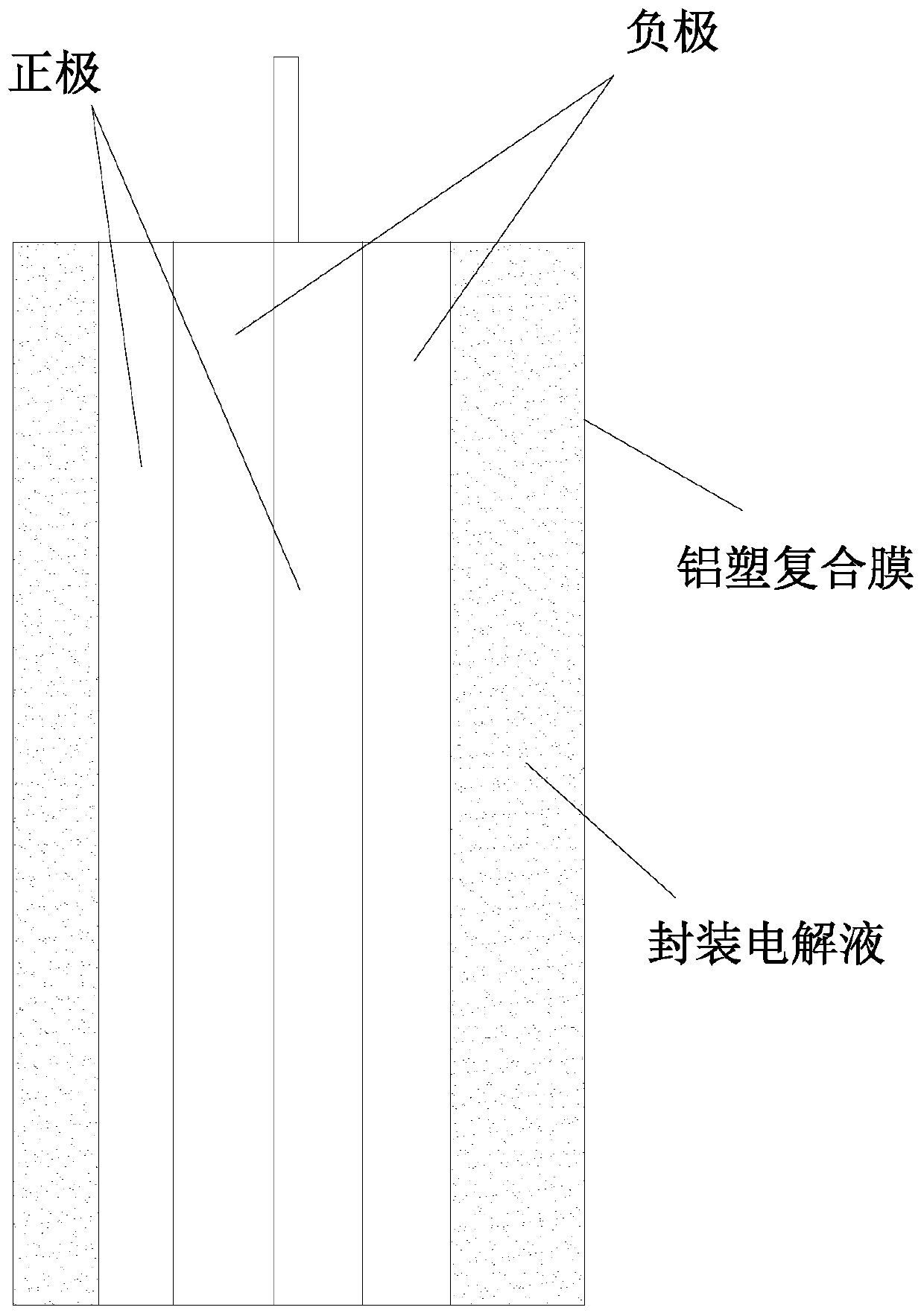

[0031] Embodiment 1: A system and method for checking the airtightness of a pouch battery, such as figure 2 Shown is the internal structure of the pouch battery. Because the aluminum-plastic composite film is easily damaged, the electrolyte in the internal package will overflow, or the electrolyte will dry out after the battery enters the air for a long time, lose its conductivity, and the electromagnetic will bulge and crack.

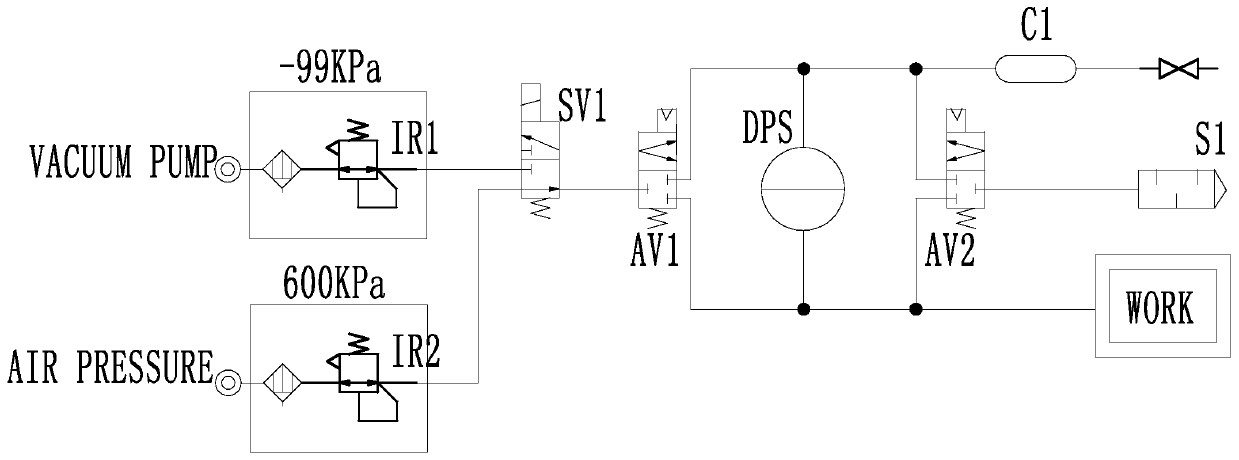

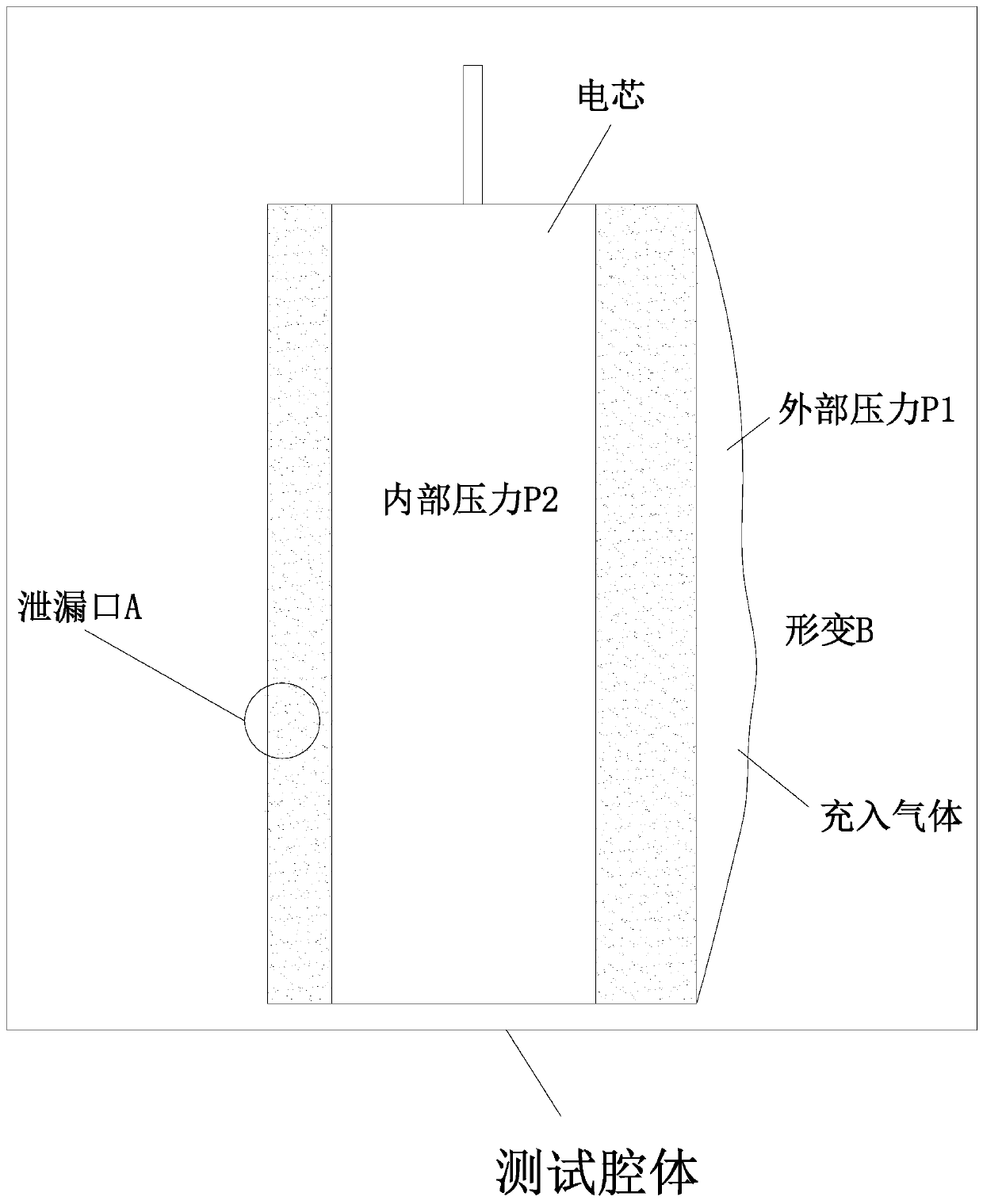

[0032] like image 3 As shown, using the air pressure or volume test, when the gas is injected into the cavity, when the battery is initially inflated, the external soft packaging will be deformed, and the internal pressure and external pressure will soon reach the same P1 = P2, the traditional air tightness inspection instrument test The method is to fill the cavity with gas first, and when the set pressure is reached, close the inflation, balance for a certain period of time, and after the pressure in the standard cavity and the test cavity are stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com