Nuclear fuel pellet having enhanced thermal conductivity and method for manufacturing the same

A technology of nuclear fuel and thermal conductivity, which is applied in the direction of reactor fuel elements, reactor fuel materials, nuclear engineering, etc., can solve the problem that the improvement effect of large thermal conductivity cannot be expected, and achieve the effect of increasing thermal conductivity, improving performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

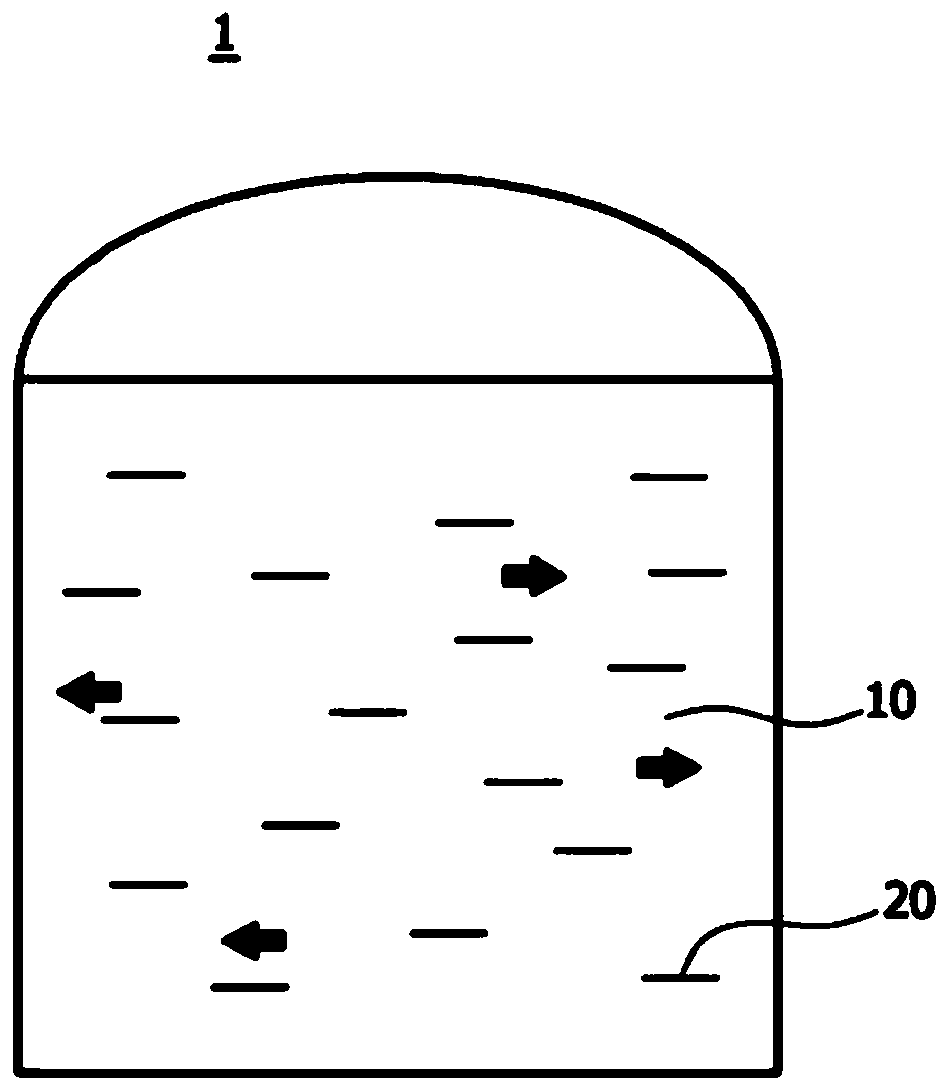

[0030] Preparation method of nuclear fuel sintered body with improved thermal conductivity

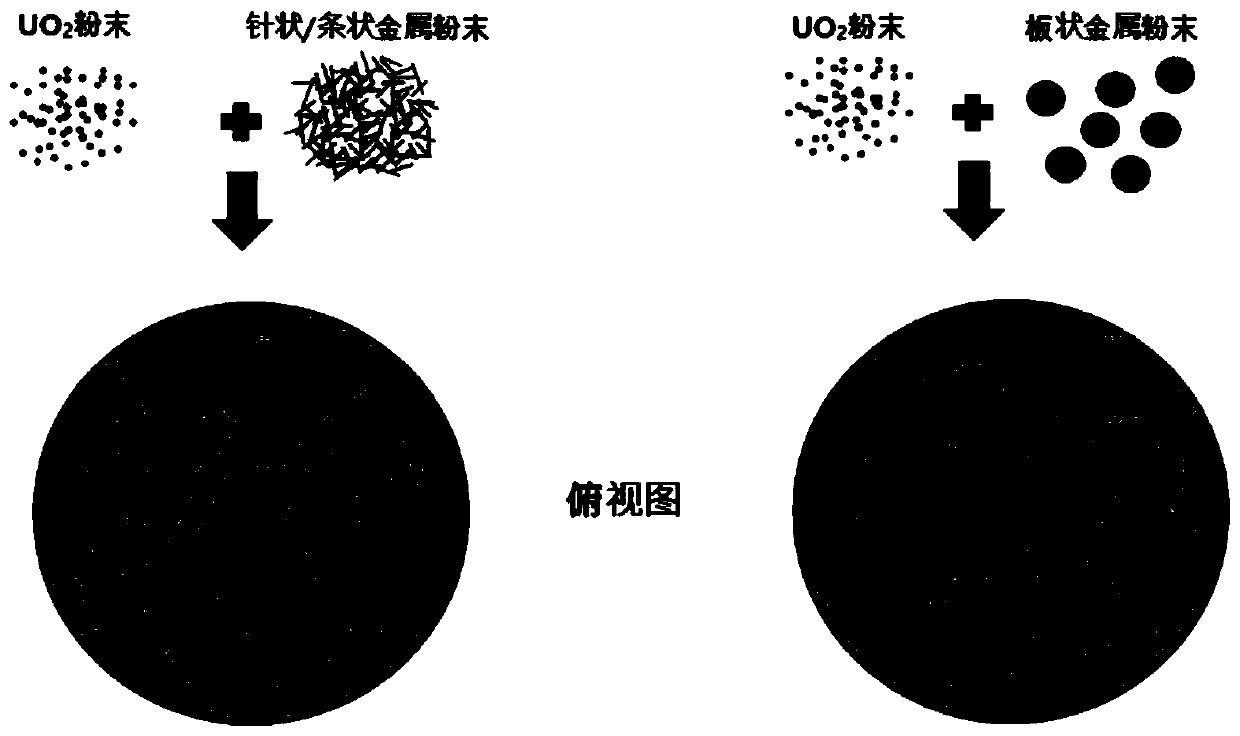

[0031] The present invention provides a method for preparing a nuclear fuel sintered body with improved thermal conductivity, which is characterized in that it includes: step (a), preparing a mixture including oxide nuclear fuel powder and plate-shaped heat-conducting metal powder; and step (b), so that The above-mentioned plate-shaped heat-conducting metal powder in the above-mentioned mixture is molded so as to have orientation in the horizontal direction, and then heat-treated to prepare a sintered body.

[0032] The term "oxide nuclear fuel powder" used in this specification is formed from an oxide nuclear fuel precursor, and refers to a state before the granulation process described below, that is, a distinct concept. Specifically, the above-mentioned oxide nuclear fuel powder refers to a powder having an average particle diameter of 0.1 μm to 50 μm. UO 2 The powder is made as...

Embodiment 1

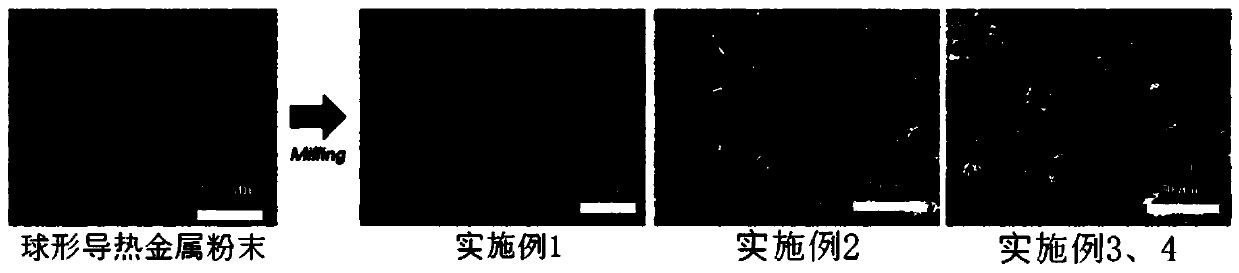

[0074] As oxide nuclear fuel powder, UO with an average particle size of about 0.3 μm was prepared 2 powder. On the other hand, a spherical Mo powder having an average particle diameter of about 0.3 μm was subjected to a grinding process to prepare a plate-like Mo powder. At this time, the prepared platy Mo powder had an average width of about 5 μm and a thickness of about 0.3 μm.

[0075] Afterwards, for prepared UO 2 powder, 5% by volume of the prepared platy Mo powder was mixed to prepare a mixture.

[0076] Then, perform uniaxial press molding under a pressure of about 300 MPa, so that the platy Mo powder has orientation in the horizontal direction in the prepared mixture, and then, in a hydrogen atmosphere, heat treatment at a temperature of about 1700 ° C for 4 hours, To prepare nuclear fuel sintered bodies.

Embodiment 2

[0078] A sintered body was prepared in the same manner as in Example 1, except that the spherical Mo powder with an average particle size of about 5 μm was ground to prepare a plate-like Mo powder with an average width of about 15 μm and a thickness of about 0.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com