Solar monocrystalline battery piece texturing process

A cell and solar energy technology, which is applied in the field of solar monocrystalline cells, can solve the problems of abnormal appearance of cells, low yield and low conversion efficiency of cells, and achieve the effect of improving cell conversion efficiency, increasing yield, and ensuring appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

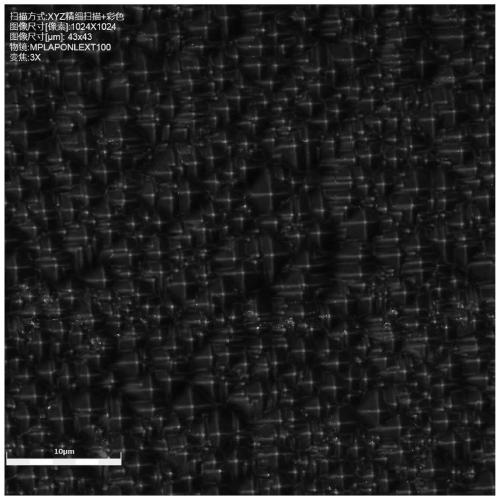

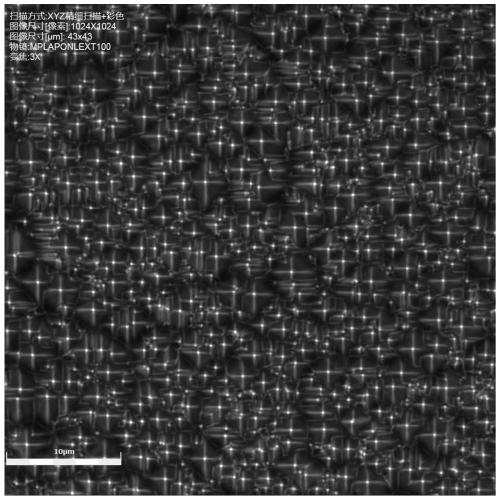

Image

Examples

Embodiment 1

[0040] (1) Put the monocrystalline cells after the silicon inspection into the flower basket through the insertion machine, and then put them into the loading area for loading;

[0041] (2) Polishing the monocrystalline cells processed in step (1) with a concentration of 3wt% sodium hydroxide solution, once for texturing, the polishing temperature is controlled at 70°C; the polishing time is controlled at 130s;

[0042] (3) Rinse the monocrystalline cells processed in step (2) for 100 seconds with pure water;

[0043] (4) The monocrystalline cells processed in step (3) are cleaned with hydrogen peroxide / sodium hydroxide mixed solution; in the hydrogen peroxide / sodium hydroxide mixed solution, the concentration of hydrogen peroxide is 8wt%, the concentration of sodium hydroxide is 3.5wt%, and the cleaning temperature is 60 ℃, cleaning time 130s;

[0044] (5) Carry out secondary rinsing with pure water for 100 s to the monocrystalline cells processed in step (4);

[0045](6) T...

Embodiment 2

[0057] (1) Put the monocrystalline cells after the silicon inspection into the flower basket through the insertion machine, and then put them into the loading area for loading;

[0058] (2) Polishing the monocrystalline cells processed in step (1) with a concentration of 5wt% sodium hydroxide solution, the polishing temperature is controlled at 65°C; the polishing time is controlled at 130s;

[0059] (3) Rinse the monocrystalline cells processed in step (2) for 100 seconds with pure water;

[0060] (4) The monocrystalline cells processed in step (3) are cleaned with hydrogen peroxide / sodium hydroxide mixed solution; in the hydrogen peroxide / sodium hydroxide mixed solution, the concentration of hydrogen peroxide is 8wt%, the concentration of sodium hydroxide is 3.5wt%, and the cleaning temperature is 60 ℃, cleaning time 130s;

[0061] (5) Carry out secondary rinsing with pure water for 100 s to the monocrystalline cells processed in step (4);

[0062] (6) Use sodium hydroxide...

Embodiment 3

[0074] (1) Put the monocrystalline cells after the silicon inspection into the flower basket through the insertion machine, and then put them into the loading area for loading;

[0075] (2) Polishing the monocrystalline cells processed in step (1) with a concentration of 2wt% sodium hydroxide solution, the polishing temperature is controlled at 60°C; the polishing time is controlled at 200s;

[0076] (3) Rinse the monocrystalline cells processed in step (2) for 200 seconds with pure water;

[0077] (4) Cleaning the monocrystalline cells processed in step (3) with hydrogen peroxide / sodium hydroxide mixed solution; the hydrogen peroxide concentration in the hydrogen peroxide / sodium hydroxide mixed solution is 5wt%, the sodium hydroxide concentration is 10wt%, and the cleaning temperature is 50°C , the cleaning time is 200s;

[0078] (5) Carry out secondary rinsing with pure water for 200 s to the monocrystalline cells processed in step (4);

[0079] (6) Use sodium hydroxide / te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com