Inorganic flexible resistive memory and preparation method thereof

A resistive memory and flexible technology, which is applied in the field of inorganic flexible resistive memory and its preparation, can solve the problems of cracks, the deterioration of storage characteristics of resistive devices, and mechanical fatigue of devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

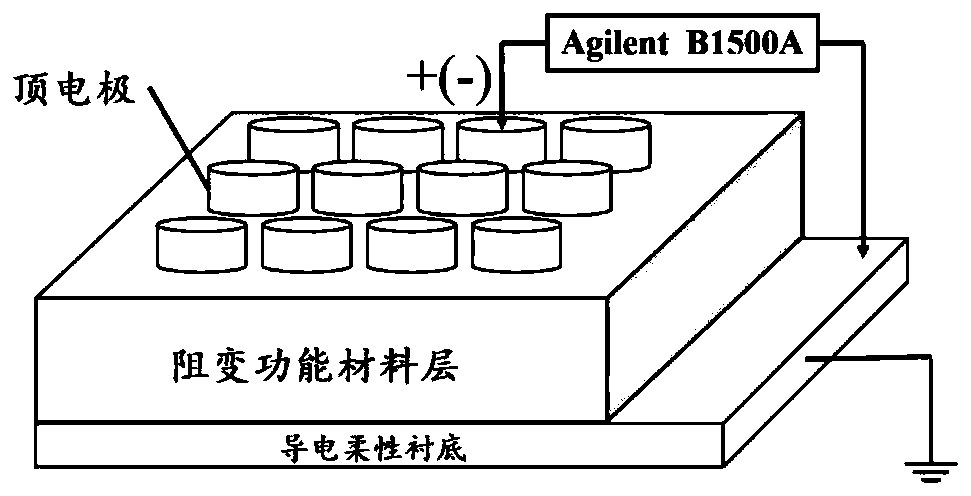

[0039] The present invention also provides a preparation method of the inorganic flexible resistive memory described in the above technical solution, comprising the following steps:

[0040] hydrothermally growing metal oxide nanorod arrays on the surface of the conductive flexible substrate to obtain a resistive functional material layer;

[0041] A top electrode layer is deposited on the surface of the resistive variable functional material layer to obtain an inorganic flexible resistive variable memory.

[0042] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0043] In the present invention, a metal oxide nanorod array is hydrothermally grown on the surface of the conductive flexible substrate to obtain a resistance-switching functional material layer; in the present invention, before the metal oxide nanorod array is hydrothermally grown on the surface of the cond...

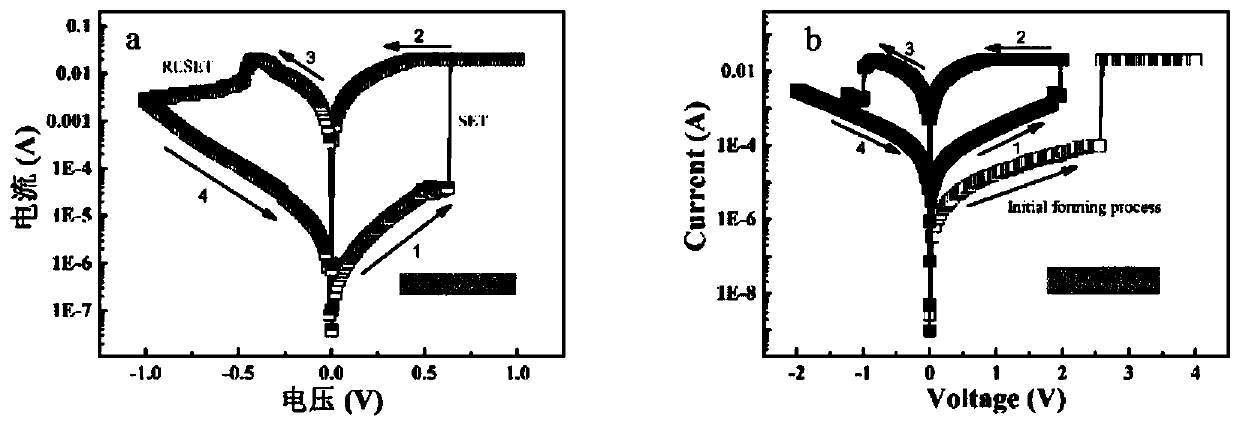

Embodiment 1

[0059] Provide TiO 2 Nanorod array precursor solution:

[0060] With saturated sodium chloride solution, 4.113g of TiCl 3 Set the volume to 40mL, stir at 30°C for 45min, add 0.48g of urea to the above solution, stir for 5h, filter to obtain TiO 2 Nanorod array precursor solution;

[0061] The titanium sheet was ultrasonically cleaned with 0.5mol / L sulfuric acid solution, acetone, deionized water, and absolute ethanol for 10-20 minutes, and then dried at 80°C for 30-50 minutes to obtain a pretreated titanium sheet (0.2mm). ;

[0062] The pretreated titanium sheet is placed in a hydrothermal reaction kettle, one end of the pretreated titanium sheet contacts the bottom of the hydrothermal reaction kettle, and the other end contacts the inner wall of the hydrothermal reaction kettle (after the pretreatment The angle between the titanium sheet and the horizontal direction is 60°C), the TiO 2 After the nanorod array precursor solution was added dropwise into the hydrothermal re...

Embodiment 2

[0067] Provide ZnO nanorod array precursor solution:

[0068] The zinc nitrate hexahydrate of 0.3005g and the hexamethylenetetramine of 0.1409g were fixed to 40ml with deionized water to obtain the ZnO nanorod array precursor solution;

[0069] The titanium sheet was ultrasonically cleaned with 0.5mol / L sulfuric acid solution, acetone, deionized water, and absolute ethanol for 10-20 minutes, and then dried at 80°C for 30-50 minutes to obtain a pretreated titanium sheet (0.2mm). ;

[0070] The pretreated titanium sheet is placed in a hydrothermal reaction kettle, one end of the pretreated titanium sheet contacts the bottom of the hydrothermal reaction kettle, and the other end contacts the inner wall of the hydrothermal reaction kettle (after the pretreatment The included angle between the titanium sheet and the horizontal direction is 60°C), the ZnO nanorod array precursor solution is added dropwise into the hydrothermal reaction kettle, and the hydrothermal reaction (90°C, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com