Method for improving quality of green tea by high-voltage electric field treatment

A technology of high-voltage electric field and high-voltage electrostatic field, which is applied in the field of improving the quality of green tea by using high-voltage electric field treatment. It can solve the problems of affecting soil management, disease and insect pests, high cost, and insignificant effect, and achieves low cost, short processing time, and freshness. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

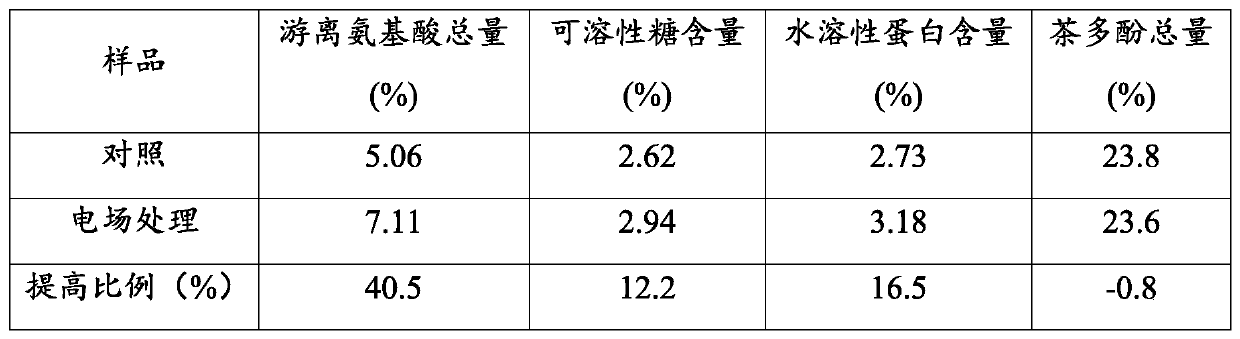

Examples

Embodiment 1

[0024] A kind of method utilizing high-voltage electric field treatment to improve the quality of green tea, specifically comprises the following steps:

[0025] (1) Picking: In fine weather, pick the fresh leaves of Longjing 43 variety tea with one bud and two leaves, and avoid damaging the young leaves when picking;

[0026] (2) Spreading and drying: Put the picked fresh leaves into the spreading and drying environment, and carry out spreading and drying treatment. The temperature of spreading and drying is controlled at 20°C, the spreading and drying thickness is 5cm, and the spreading and drying time is 4 hours, so as to control the water content of the fresh tea leaves rate at 70%;

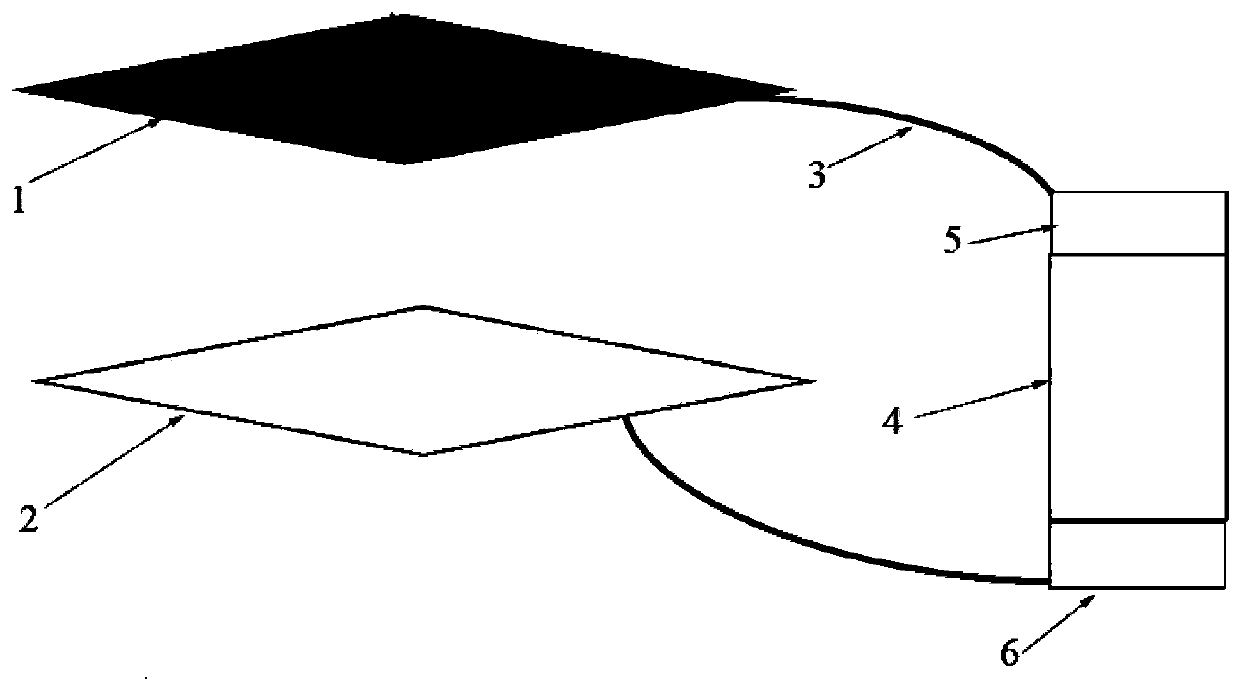

[0027] (3) Electric field treatment: in the process of electric field treatment, figure 1 The middle device is carried out, and this device comprises upper metal plate 1, lower metal plate 2 and power supply 4, and upper metal plate 1 is connected with the power positive pole 5 of power supp...

Embodiment 2

[0037] (1) Picking: In fine weather, pick fresh tea leaves with one bud and two leaves, and avoid damaging the tender leaves when picking;

[0038] (2) Spreading and airing: put the picked fresh tea leaves into the airing environment, and carry out spreading and drying treatment. The temperature of spreading and drying is controlled at 22°C, the thickness of spreading and drying is 10cm, and the spreading time is 6 hours, so as to control the water content of the tea leaves rate at 65%;

[0039] (3) Electric field treatment: Utilize the electric field treatment device among the embodiment 1 to process, tea leaves are transferred in batches in the high voltage electric field, utilize the electric field strength of high voltage electrostatic field to be 8kv / cm, processing time is 60min, fresh tea leaves are processed The amount is 5kg / m 2 ;

[0040] (4) Finishing: place the tea leaves that have been treated by the electric field in a drum-type fixing machine, and fix them at 3...

Embodiment 3

[0047] (1) Picking: In fine weather, pick fresh tea leaves with one bud and two leaves, and avoid damaging the tender leaves when picking;

[0048] (2) Spreading and airing: put the picked fresh tea leaves into the spreading and drying environment, and carry out spreading and drying treatment. The temperature of spreading and drying is controlled at 25°C, the spreading and drying thickness is 8cm, and the spreading and drying time is 5 hours, so as to control the water content of the tea leaves rate at 68%;

[0049] (3) Electric field treatment: Utilize the electric field treatment device among the embodiment 1 to process, tea leaves are transferred in batches in the high-voltage electric field, utilize high-voltage electrostatic field to process, the electric field strength of high-voltage electrostatic field is 20kv / cm, processing time 10min, fresh tea processing capacity is 5kg / m 2 ;

[0050] (4) Finishing: place the tea leaves that have been treated by the electric field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com