Environment-friendly urethane foam insulation material and preparation method thereof

A technology of polyurethane foam and thermal insulation materials, applied in the field of thermal insulation materials, can solve problems such as damage, reduce production costs and improve environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

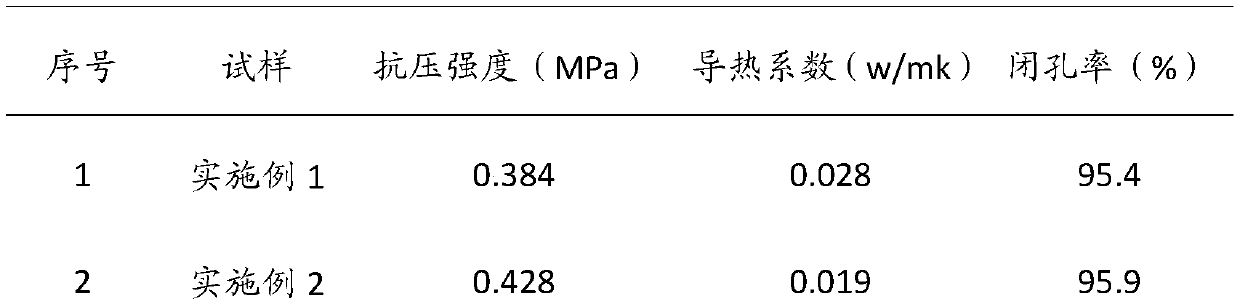

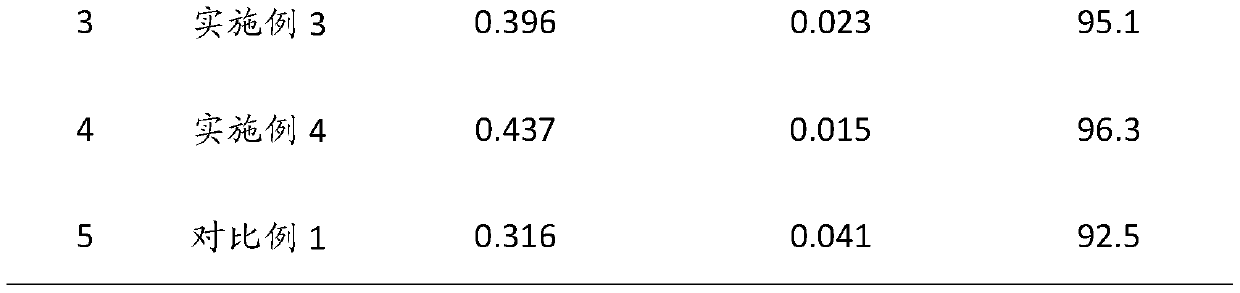

Examples

Embodiment 1

[0024] An environment-friendly polyurethane foam insulation material, made of the following raw materials: 100kg of polyether polyol, 100kg of isocyanate, 1kg of catalyst, 2kg of water, 2kg of pulp waste liquor with a pH of 9 obtained from alkaline pulping, and 1kg of foam stabilizer;

[0025] The above-mentioned environment-friendly polyurethane foam insulation material is prepared by the following steps:

[0026] S1: Weigh the following raw materials respectively, polypolyol (a mixture of pentaerythritol ether and glycerol polyether in a mass ratio of 1:3, with a hydroxyl value of 500mgKOH / g and a viscosity of 3600mPa·s) 100kg, isocyanate 100kg, catalyst ( N, N-dimethylcyclohexylamine) 1kg, water 2kg, pulp waste liquid 2kg, foam stabilizer (silicone oil) 1kg;

[0027] S2: Put polyether polyol, catalyst, water, pulp waste liquid and foam stabilizer in a mixer, and stir evenly for 30 minutes to prepare mixture a;

[0028] S3: under stirring conditions, add isocyanate to the m...

Embodiment 2

[0031] An environment-friendly polyurethane foam insulation material, made of the following raw materials: 120kg of polyether polyol, 130kg of isocyanate, 3kg of catalyst, 4kg of water, 5kg of pulp waste liquor with a pH of 10 obtained from alkaline pulping, and 3kg of foam stabilizer;

[0032] The above-mentioned environment-friendly polyurethane foam insulation material is prepared by the following steps:

[0033] S1: Weigh the following raw materials respectively, polyether polyol (a mixture of pentaerythritol ether and glycerol polyether in a mass ratio of 1:5, the hydroxyl value is 520mgKOH / g, and the viscosity is 3700mPa·s100kg) 120kg, isocyanate 130kg, catalyst ( Diethanol monoisopropanolamine) 3kg, water 4kg, pulp waste liquid 5kg, foam stabilizer (silicone oil) 3kg;

[0034] S2: Put polyether polyol, catalyst, water, pulp waste liquid and foam stabilizer in a mixer, and stir evenly for 40 minutes to prepare mixture a;

[0035] S3: under stirring conditions, add isocy...

Embodiment 3

[0038] An environmentally friendly polyurethane foam insulation material, made of the following raw materials: 140kg of polyether polyol, 150kg of isocyanate, 5kg of catalyst, 6kg of water, 6kg of pulp waste liquor with a pH of 9.2 obtained from alkaline pulping, and 4kg of foam stabilizer;

[0039] The above-mentioned environment-friendly polyurethane foam insulation material is prepared by the following steps:

[0040] S1: Weigh the following raw materials respectively, polyether polyol (a mixture of pentaerythritol ether and glycerol polyether in a mass ratio of 1:4, the hydroxyl value is 510mgKOH / g, and the viscosity is 3650mPa·s100kg) 140kg, isocyanate 150kg, catalyst ( Hydroxyethylethylenediamine) 5kg, water 6kg, pulp waste liquid 6kg, foam stabilizer (silicone oil) 4kg;

[0041] S2: Put polyether polyol, catalyst, water, pulp waste liquid and foam stabilizer in a mixer, and stir evenly for 45 minutes to prepare mixture a;

[0042] S3: under stirring conditions, add iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com