Thermodynamic cooling power tower

A technology for power generation towers and power generation systems, applied in wind power generation, renewable energy power generation, engines, etc., can solve problems such as high failure rate, large component wear, and low efficiency, and achieve the goal of reducing pollution, reducing consumption, and reducing power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

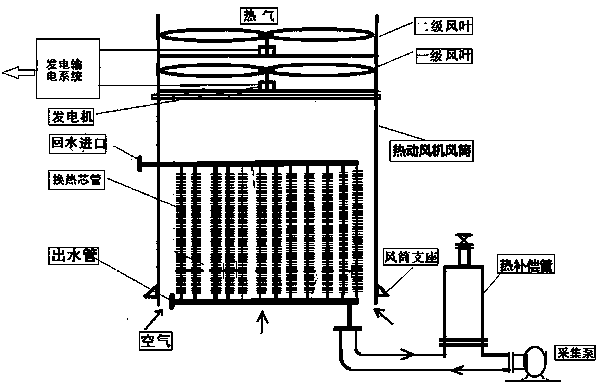

[0024] Such as figure 1 The thermodynamic cooling power generation tower shown has a thermodynamic fan and a vertical fan blade power generation system; the thermodynamic fan consists of an air duct, and a heat medium collection system and a heat medium distribution system arranged in sequence according to the flow direction of the heat medium inside the duct. Tubes and heat exchange core tubes.

[0025] The thermal fan self-suctions a huge amount of air to cool the heat medium in the heat exchange core tube. The heat medium is a high-temperature liquid at the bottom of the distillation tower; the airflow sucked by the thermal fan performs heat exchange with the heat medium in the heat exchange core tube After being heated, it becomes low-density hot air. Under the action of the "chimney effect" of the air duct, a rising hot air flow with a basically constant speed is formed and blown out from the top of the air duct.

[0026] In actual application, the circulating cooling wa...

Embodiment 2

[0028] The return water (heat medium) flow rate of the circulating cooling water in Example 1 is 116m3 / h, the return water pressure is 0.22MPa, and the temperature is 44°C. MPa. The exhaust air velocity at the top of the air duct is 2.2m / s, the exhaust air temperature is 40°C, the rotation speed of the vertical power generation fan blade is 72rpm, and the total power generation is 65kw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com