Chemical looping combustion device using ash

A technology of chemical looping combustion and separation device, which is applied in the direction of fluidized bed combustion equipment, fuel burned in molten state, combustion type, etc., and can solve the problem of low effective utilization of metal oxygen carriers, large demand for metals, complex equipment, etc. problems, to achieve the effect of promoting widespread use, saving metal raw materials, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

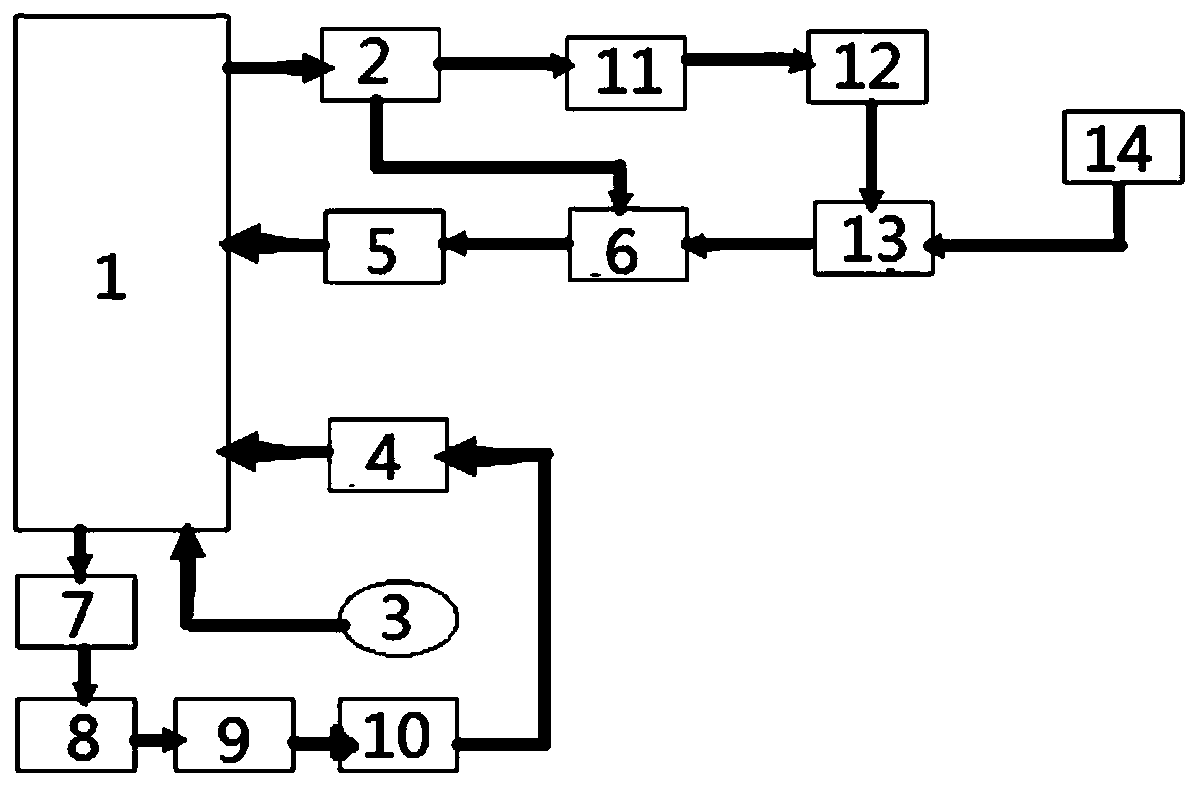

[0017] Such as figure 1 As shown, the chemical looping combustion device using ash of the present invention is mainly used for low emission of fluidized bed boilers and resource-saving circular combustion. The device is composed of a circulating fluidized bed system, a cinder treatment system, an ash treatment system and a fly ash circulation system.

[0018] The circulating fluidized bed system includes a fluidized bed 1, a cyclone separator 2, a blower 3, a gas burner 4, a swirl burner 5, and a coke pretreatment device 6. The cinder treatment system includes a drum type slag cooler 7 and an ash separation device 8 . The ash processing system includes a coagulation device 9 and a ball mill 10 . The fly ash circulation system includes a heat exchanger 11 , a dust collector 12 , a coal mill 13 and a coal feeding system 14 .

[0019] The outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com