Nitrogen oxide catalytic reaction net

A catalytic reaction and nitrogen oxide technology, applied in the field of reaction nets, can solve the problems of catalytic reaction nets that cannot withstand high temperatures, low reaction efficiency, and long distances, and achieve high resistance to peeling, effective reactions, and good high temperature resistance. Effects of Corrosion and Oxidation Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

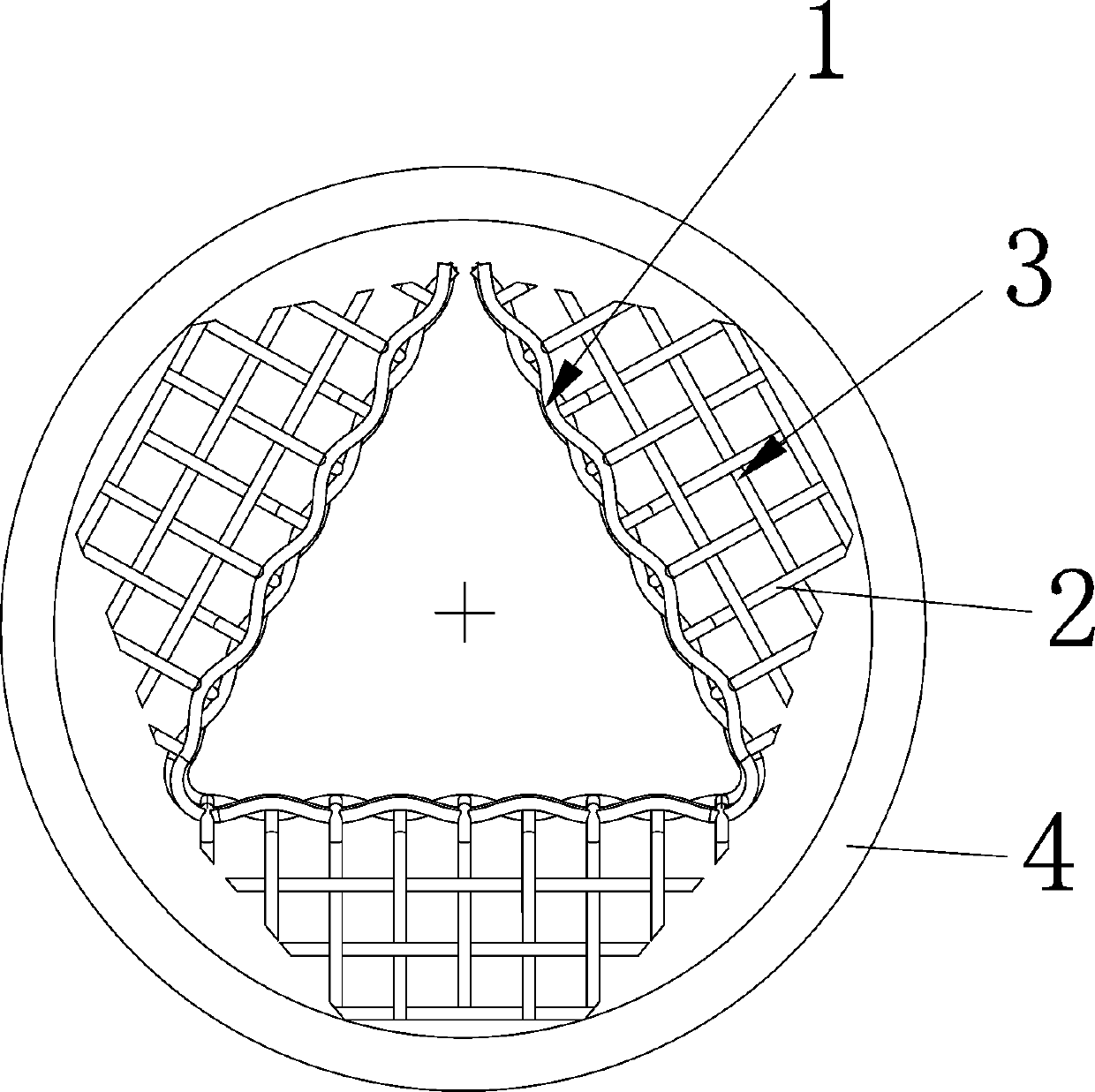

Image

Examples

Embodiment 2

[0025] Embodiment 2: Compared with Embodiment 1, the difference lies in the shape of the flanging, and the rest are the same.

[0026] The shape of the flanging can also directly adopt a trapezoidal shape, which reduces the process and can also effectively contact the flame, which is beneficial to the reaction.

Embodiment 3

[0027] Embodiment 3: Compared with Embodiment 1, the difference is that the mass fraction of silk thread is different, and the rest are the same.

[0028] The silk thread includes the following components in parts by mass: 0.031 parts of carbon, 0.4 parts of silicon, 0.12 parts of manganese, 0.0043 parts of sulfur, 58.1 parts of nickel, 23.1 parts of chromium, 0.28 parts of titanium, 1.61 parts of aluminum, 0.023 parts of calcium, boron 0.0005 parts and iron 16.3312 parts. One of the advantages of using this formula is that it can withstand high temperatures above 1200°C.

[0029] According to the experiment, compared with the original structure, the emission of the reaction net of the present invention is reduced from 34 joules to 15 joules.

Embodiment 4

[0030] Embodiment 4: Compared with Embodiment 1, the difference is that the mass fraction of the thread, the side length of the through hole, the diameter of the thread, and the density of the thread are different, and the rest are the same.

[0031] The side length of the through holes formed by interweaving silk threads in the reaction net is 2.51 mm, the diameter of the silk threads is 0.8 mm, and the shape of the through holes is square. In this way, the rate of reaction can be achieved the fastest.

[0032] The thread has a density of 8.21 g / cm³.

[0033] The silk thread includes the following components in parts by mass: 0.032 parts of carbon, 0.41 parts of silicon, 0.19 parts of manganese, 0.0038 parts of sulfur, 57.7 parts of nickel, 22.9 parts of chromium, 0.27 parts of titanium, 1.35 parts of aluminum, 0.018 parts of calcium, boron 0.0004 parts and iron 17.3258 parts. One of the advantages of using this formula is that it can withstand high temperatures above 1200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com